Challenge: Inspecting a Diesel Storage Tank

Regular inspections must be conducted for industrial tanks to ensure their structural integrity. However, traditional inspection methods present several setbacks:

- Emptying and cleaning the tank to make it safe for human entry

- Building scaffolding to reach various parts of the tank

- Manual measurements for thickness and corrosion checks

These steps are not only time-consuming and expensive but also pose significant risks to workers operating in confined spaces and at heights.

Birdseye Solution

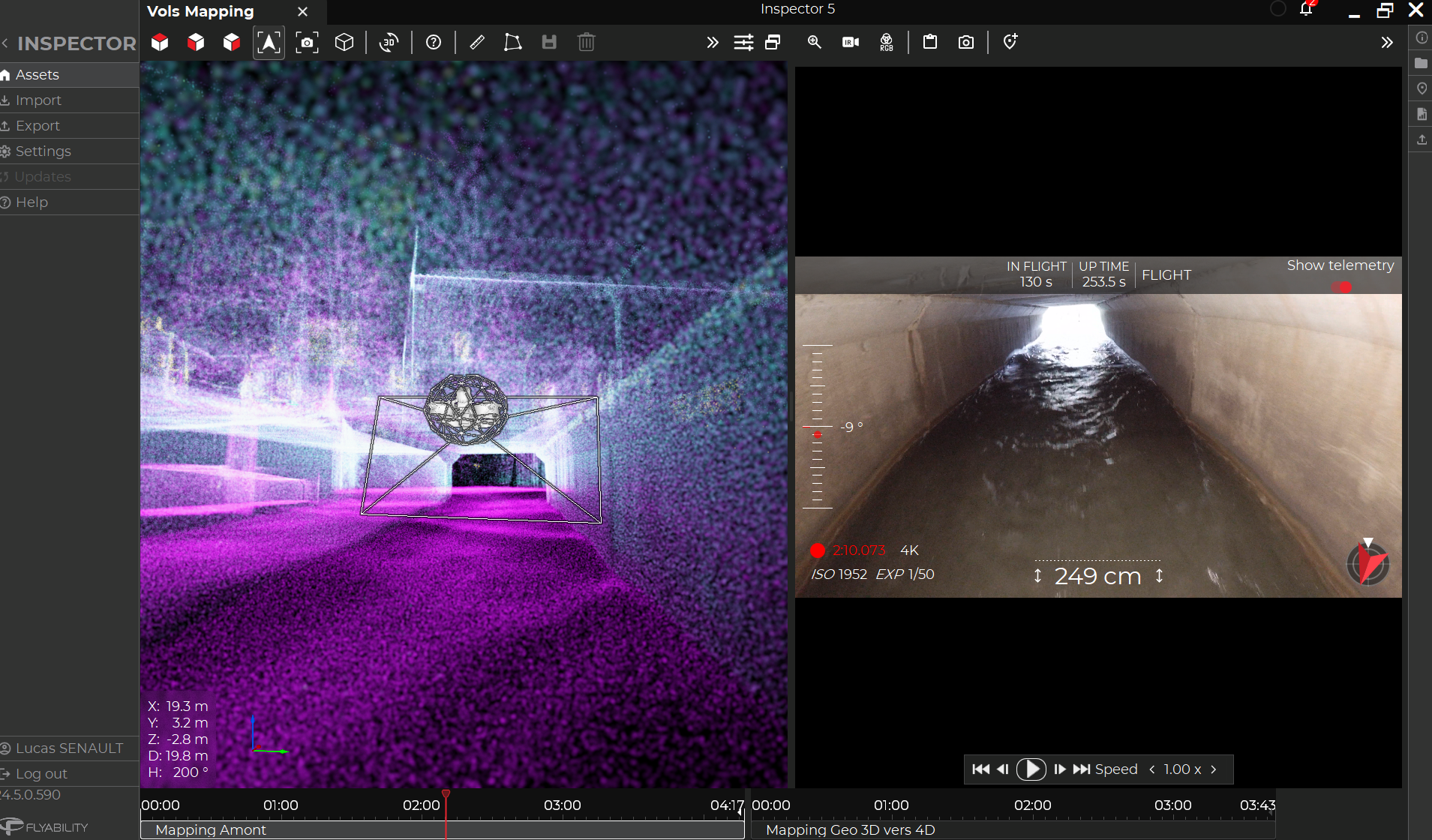

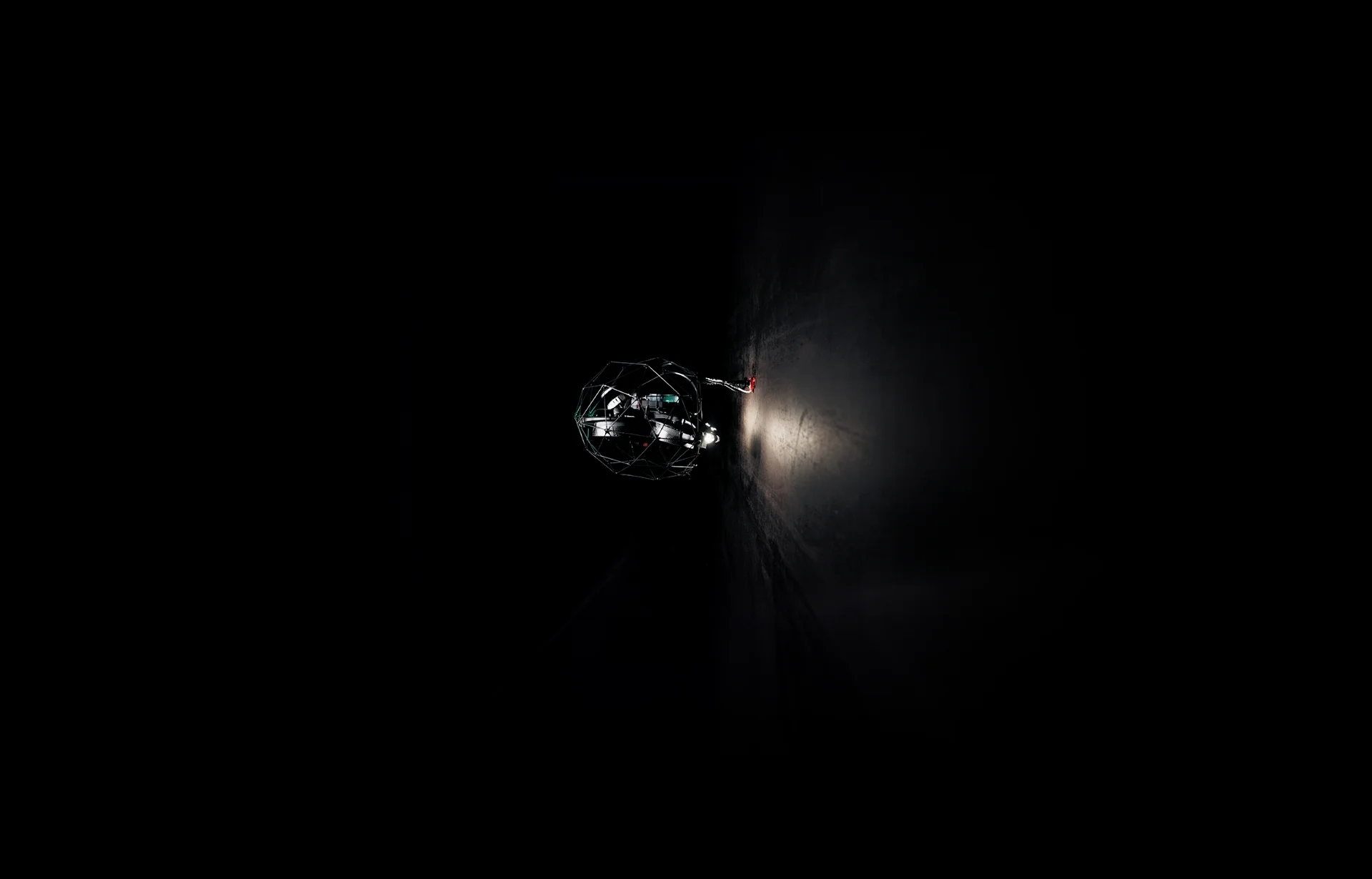

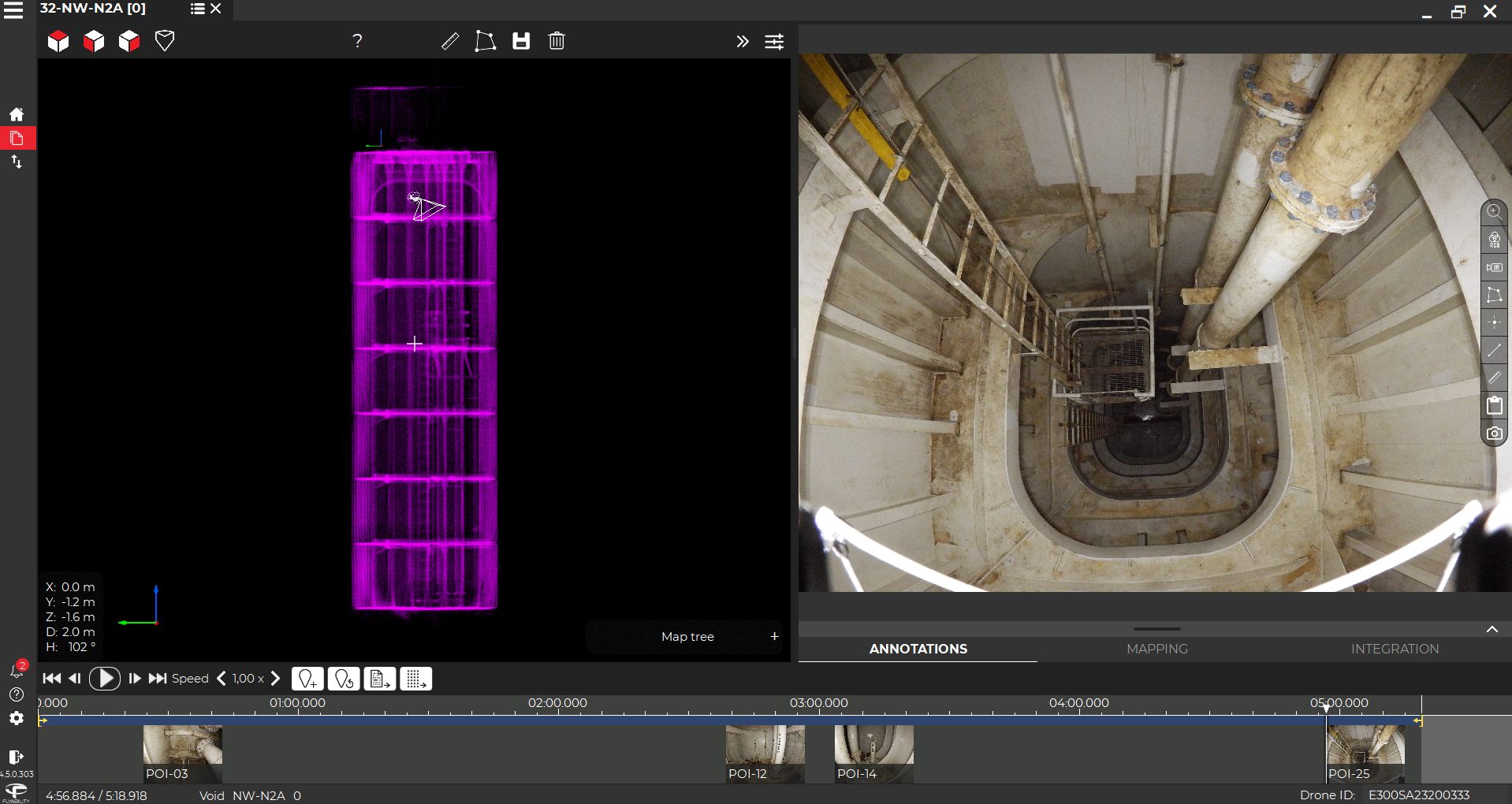

Leveraging advanced drone technology, the Elios 3 provided a safer, more efficient, and faster alternative for tank inspections.

Key Benefits

| Aspect | Details |

|---|---|

| Access | Agile and compact, the drone easily flew inside the narrow double wall of the tank. |

| Safety | Eliminated the need for human entry, reducing risks and improving safety. |

| Speed | Completed 84 ultrasonic measurements across 4 scan lines, outperforming manual methods. |

| Efficiency | Minimized operational downtime and integrated seamlessly into workflows. |

Outcome

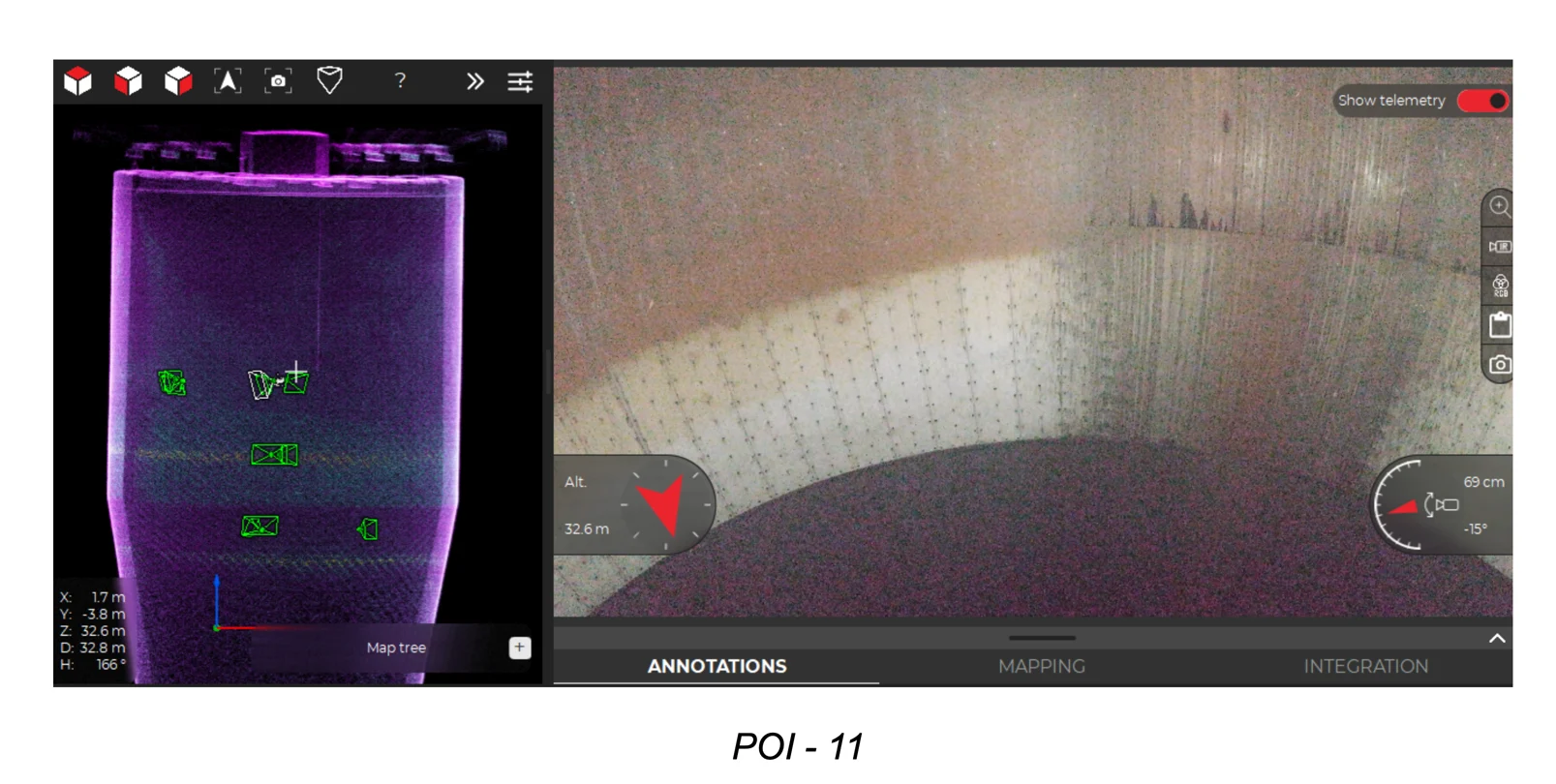

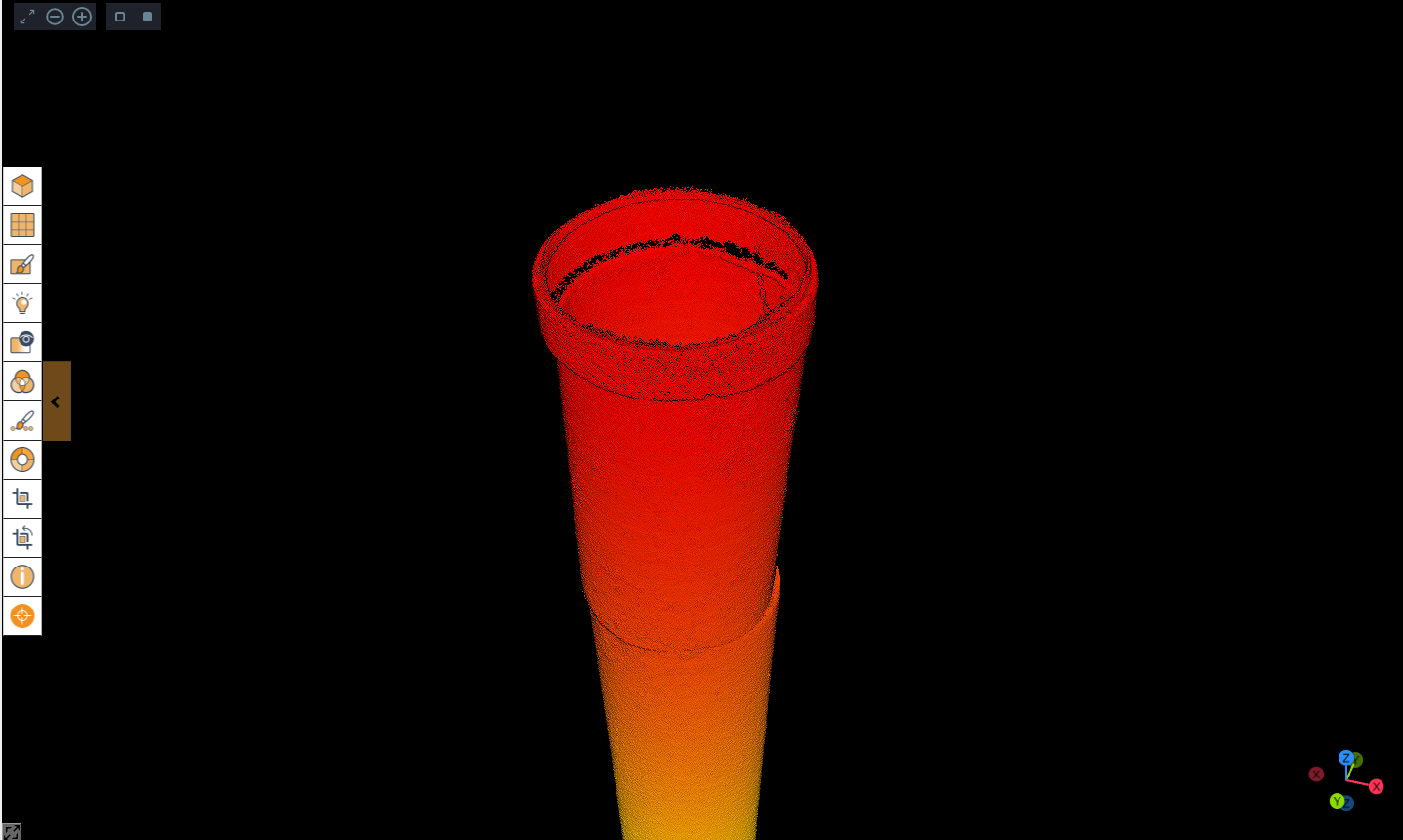

- Comprehensive Data Collection: 84 ultrasonic thickness measurements across 4 scan lines, with 3 readings from 7 plates per line.

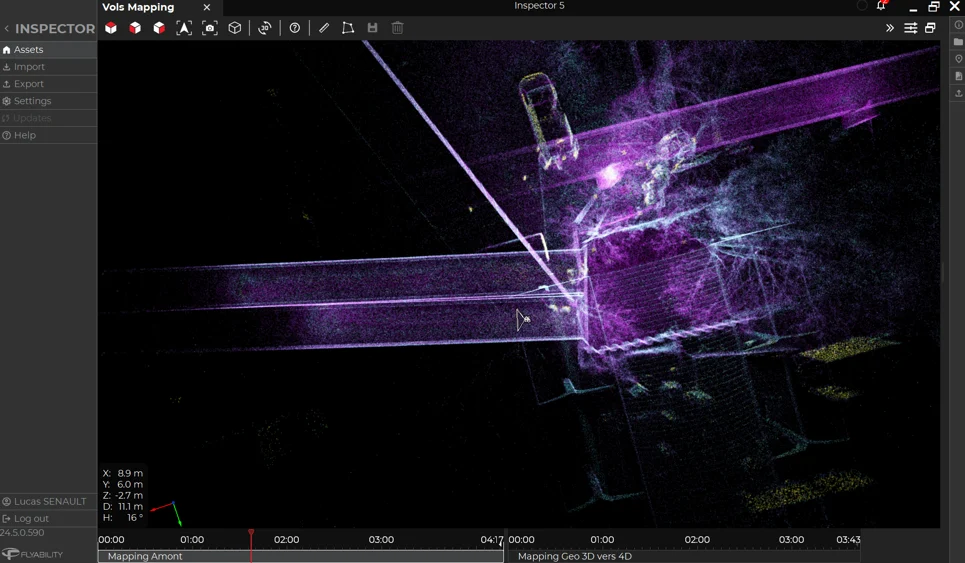

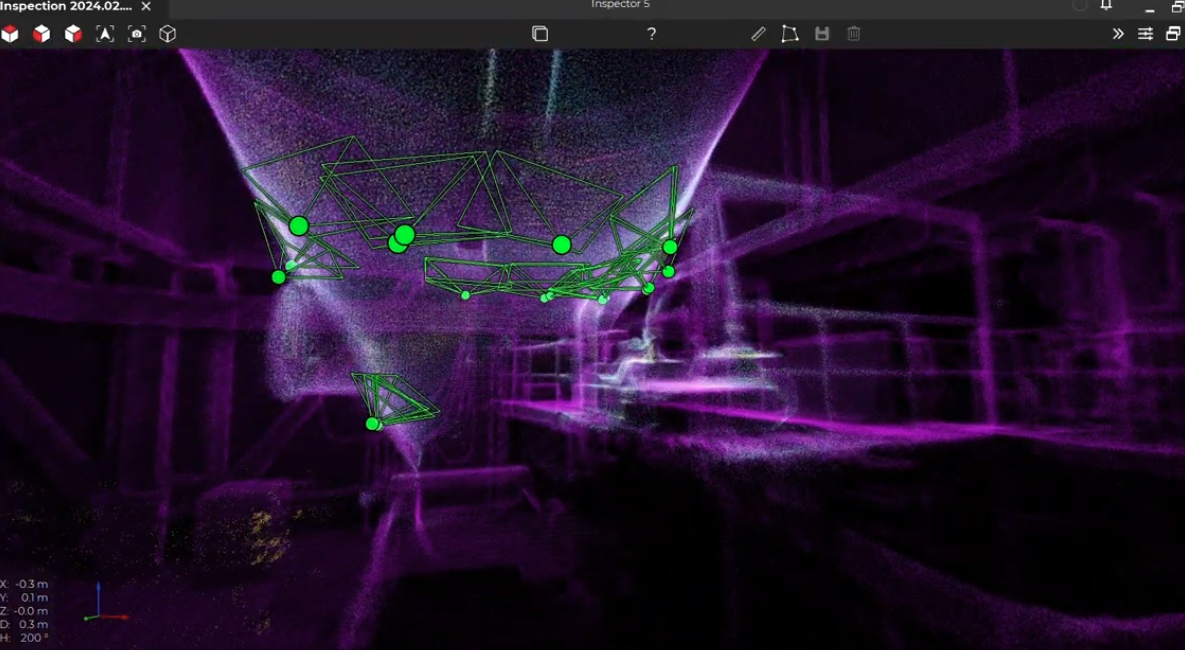

- Precise Localization: The LiDAR system generated a 3D point cloud, enabling accurate localization of measurement points for ongoing monitoring and planning.

Conclusion: A New Standard in Tank Inspections

This case demonstrates how drone technology is revolutionizing industrial inspections by enhancing safety, reducing costs, and increasing operational efficiency.

At Birdseye, we’re proud to help clients achieve better outcomes with cutting-edge aerial robotics—pushing the limits of what’s possible in industrial asset integrity management.