Overview

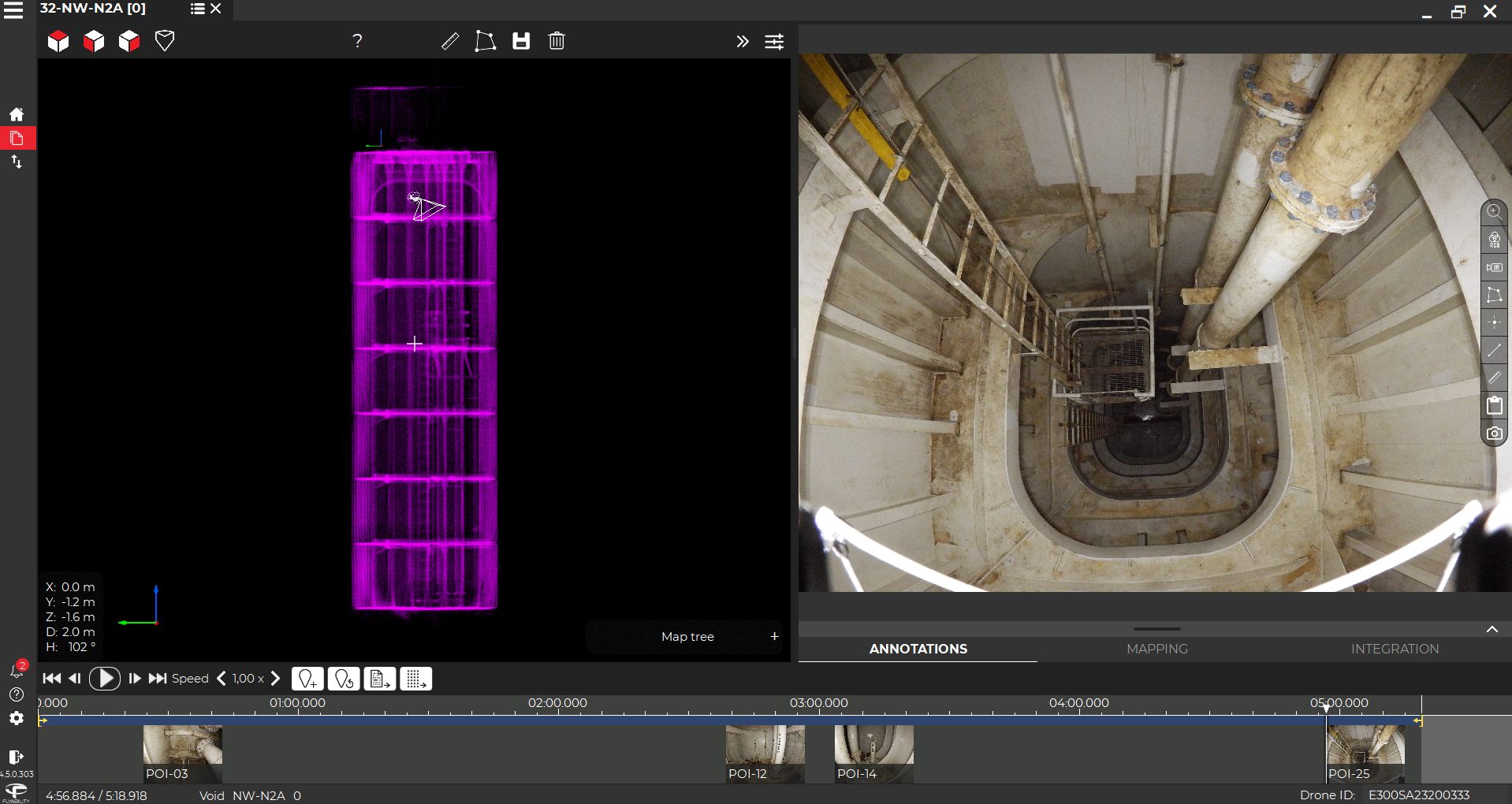

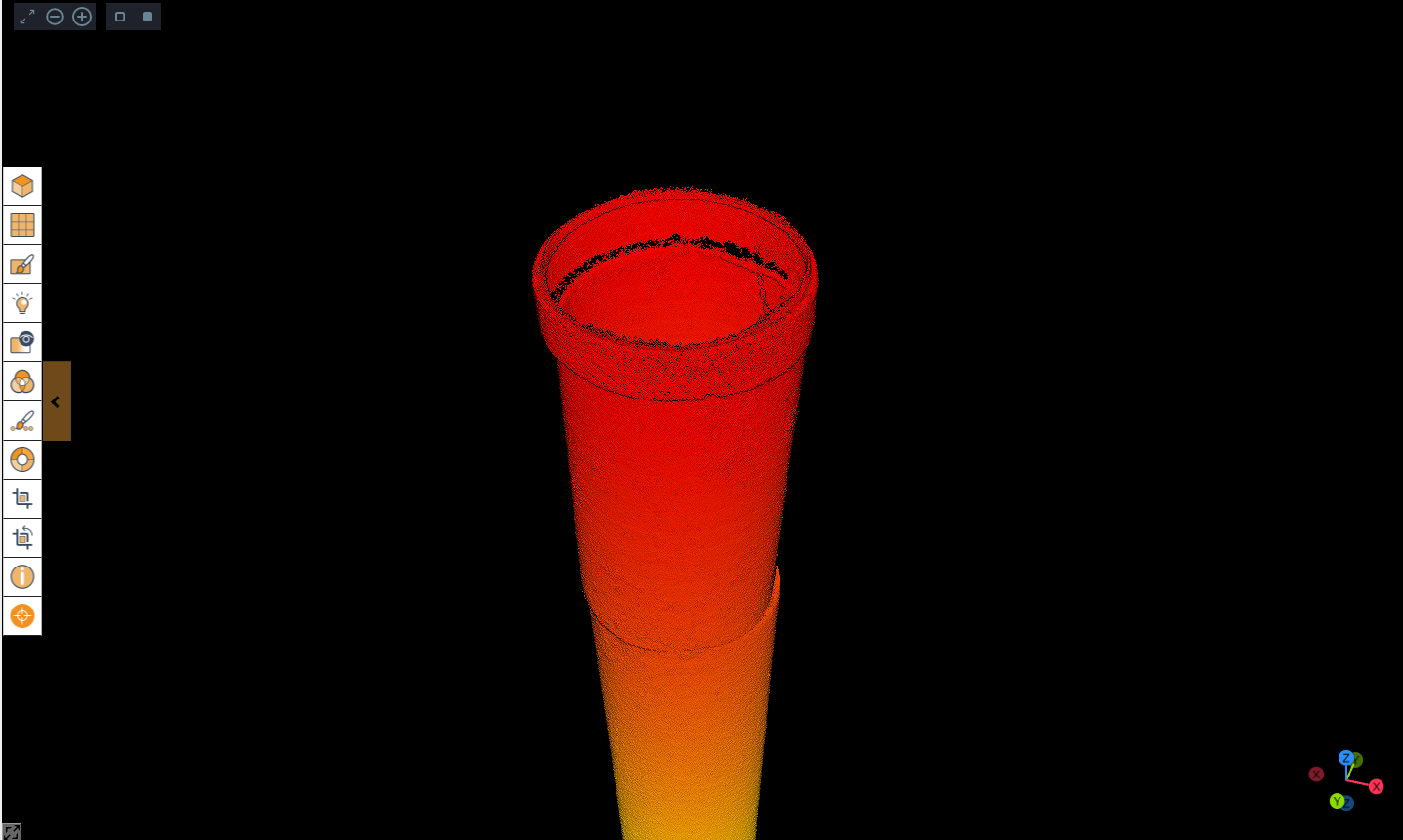

A newly built quarry furnace, 190 meters high and 4 meters wide, affected by rock detachments had to be examined for structural integrity and maintenance planning while minimizing operational disruption.

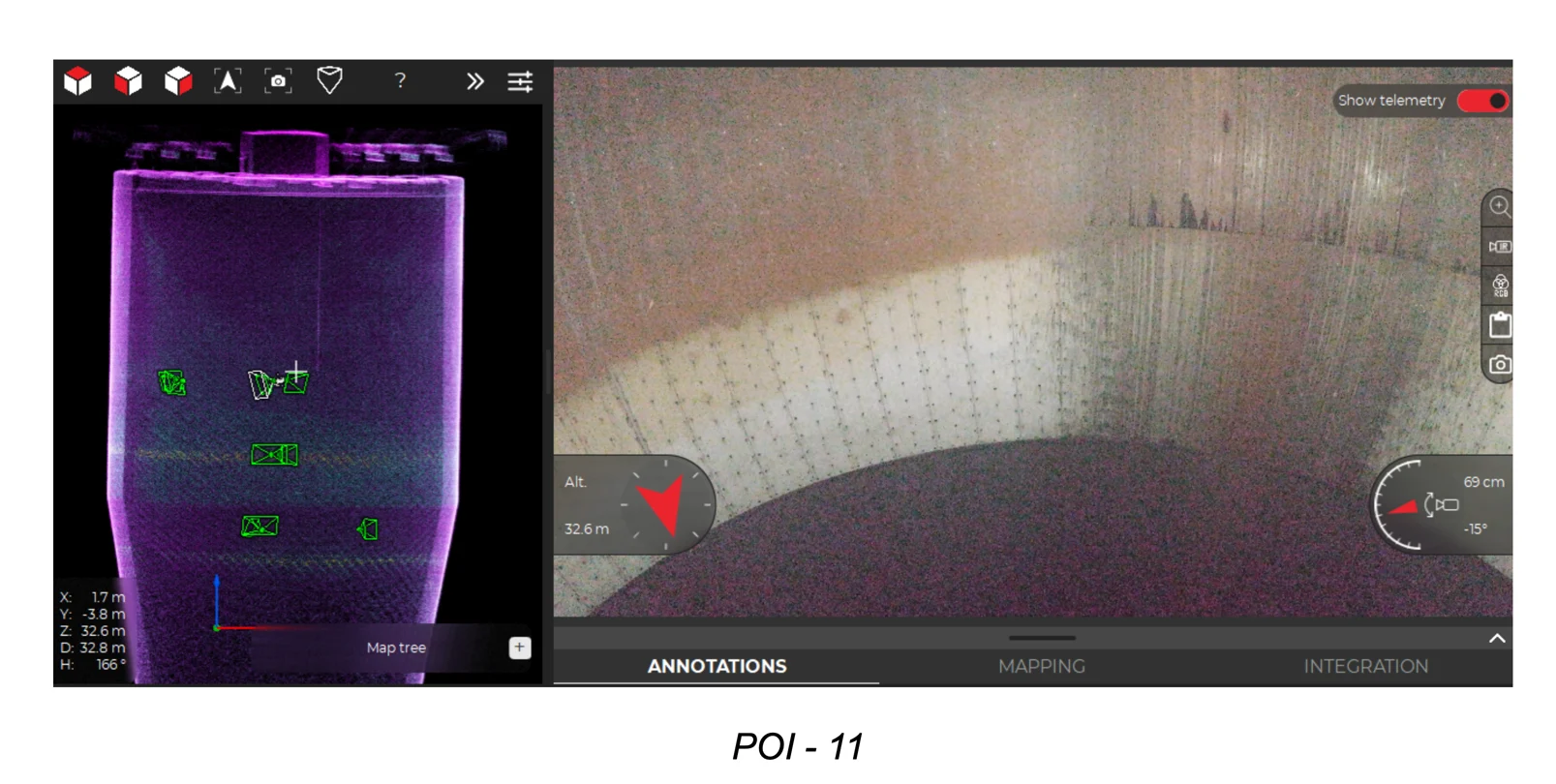

The main objective was to find out the key reasons behind the rock detachments in the base chamber of the quarry and analyze its condition.

Challenges Faced in Ancient Inspection Method

- Hazardous Environment: It was unsafe for inspectors to review the furnace due to hazardous rock detachments posing serious risks.

- Confined Space Complexity: Workers had a tough time entering confined spaces as the furnace was narrow (4 meters wide) and deep, not only making it unsafe but also time-consuming.

- Operational Constraints: Since lime plays a primary role in multiple sectors of the country, it was critical to avoid disrupting ongoing operations while reducing downtime.

Solutions Delivered by Birdseye

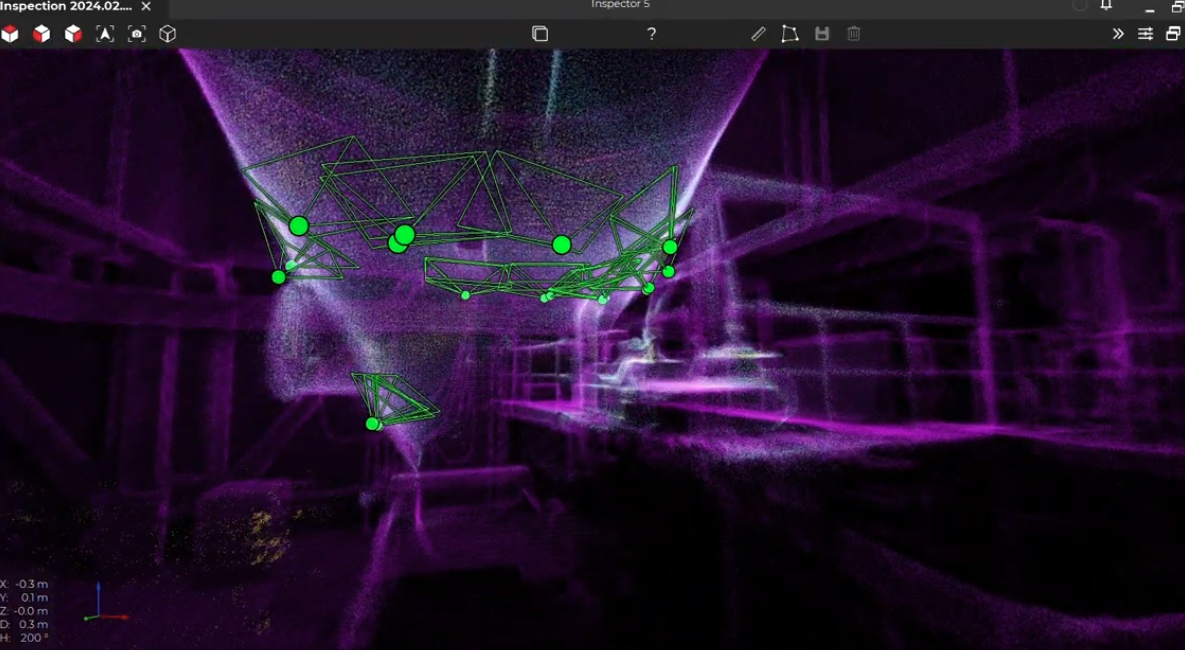

Elios drone’s features and software used facilitated in achieving the outcome.

| Solution | Elios Feature / Technology Used |

|---|---|

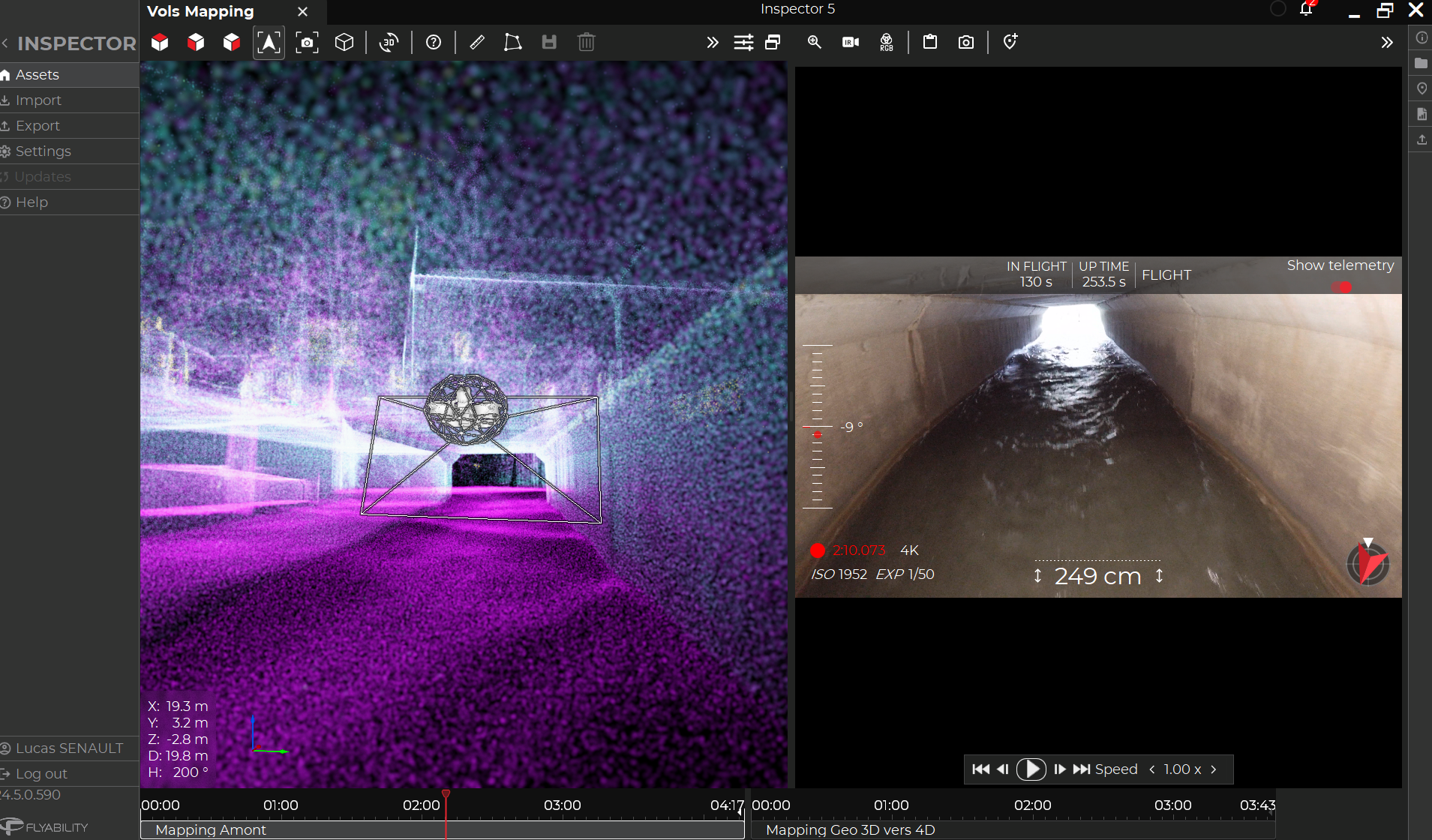

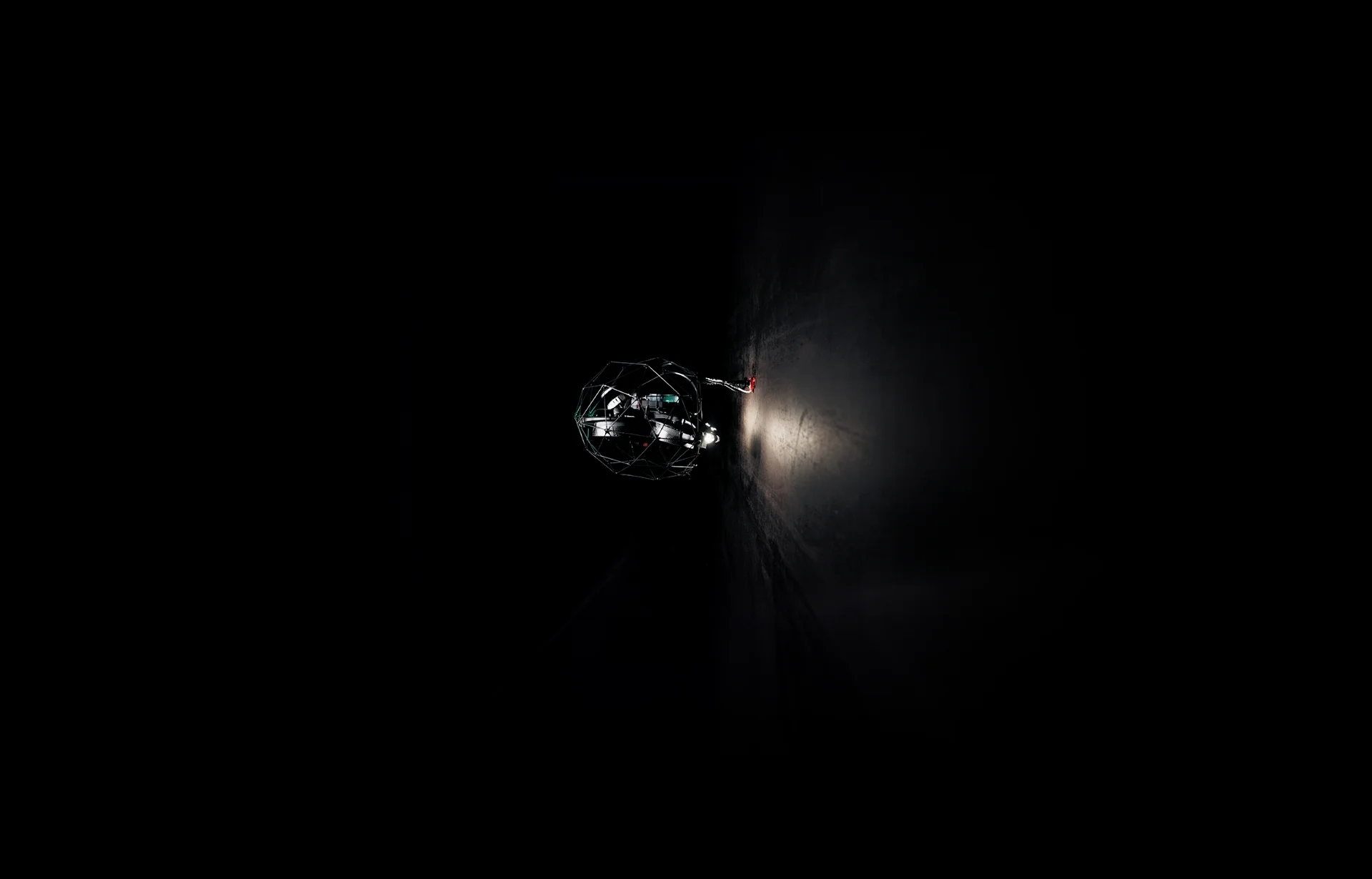

| Safe Access to Confined Spaces | The drone’s compact design and protective cage enabled flight through a 190-meter-high furnace and operated safely in high-risk areas. |

| Rapid Data Collection | Drone’s forefront innovative technology completed inspection in just 4 flights lasting under 30 minutes. |

| High-Quality Visual Data | Powerful camera and integrated LED lights captured detailed images and videos of structural issues. |

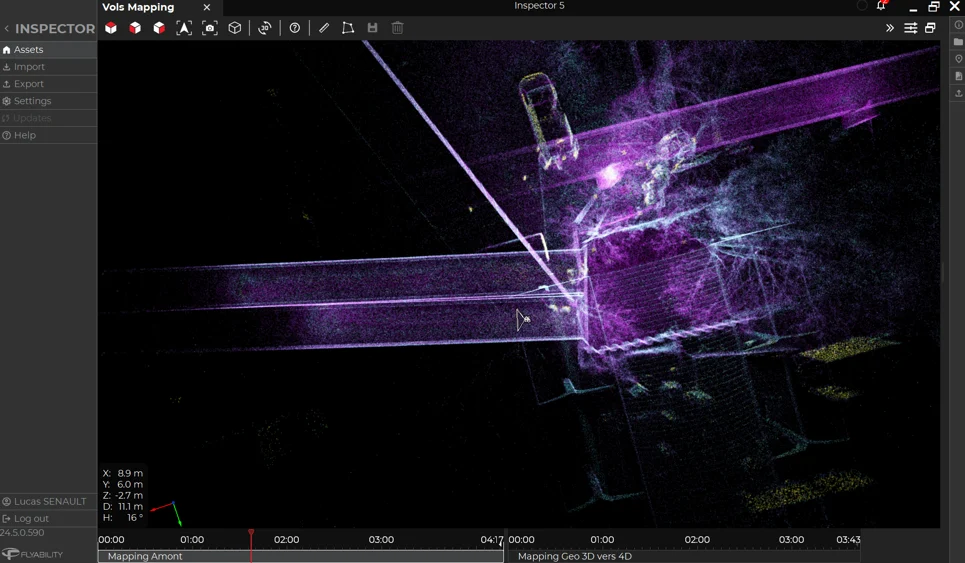

| 3D Digital Twin Creation | LiDAR sensor generated a 3D point cloud model of the furnace interior for precise structural visualization. |

Conclusion

The use of Birdseye’s drone clearly identified the root cause of rock detachments in the base chamber, supporting the development of a targeted maintenance strategy. The inspection process significantly enhanced safety by removing the need for human entry into hazardous spaces. Additionally, the drone delivered fast, accurate, and actionable data — all while ensuring minimal disruption to lime production.