The Main Issue

The conventional method of inspecting stormwater pipelines presents several challenges:

- Dependence on manual CCTV inspections delays the inspection process, and workers may not give a full picture of the asset condition.

- Taking up an immense amount of time to clean the tunnels.

- Physically entering enclosed spaces increases risk and danger level (risk of toxic gases, biohazards, and falls).

The Solution

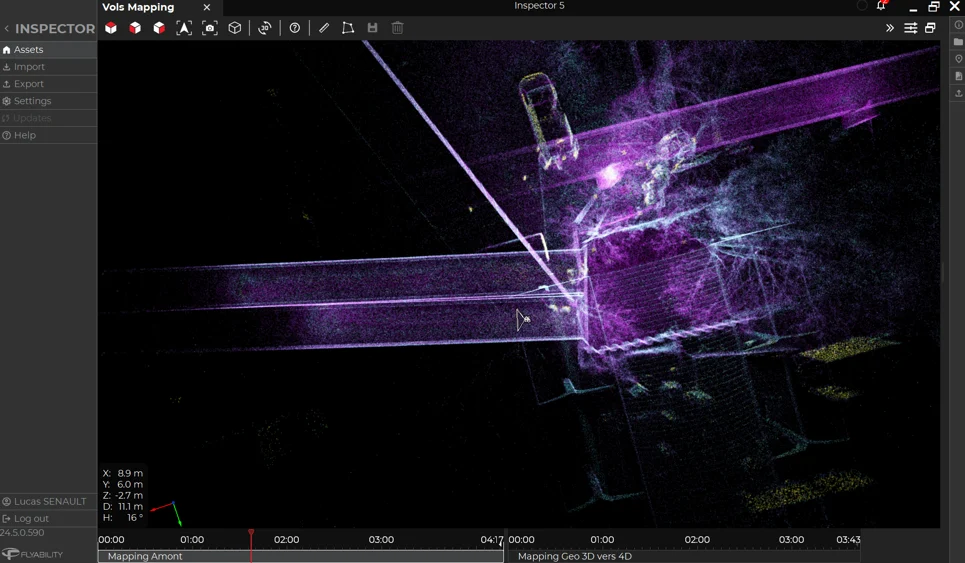

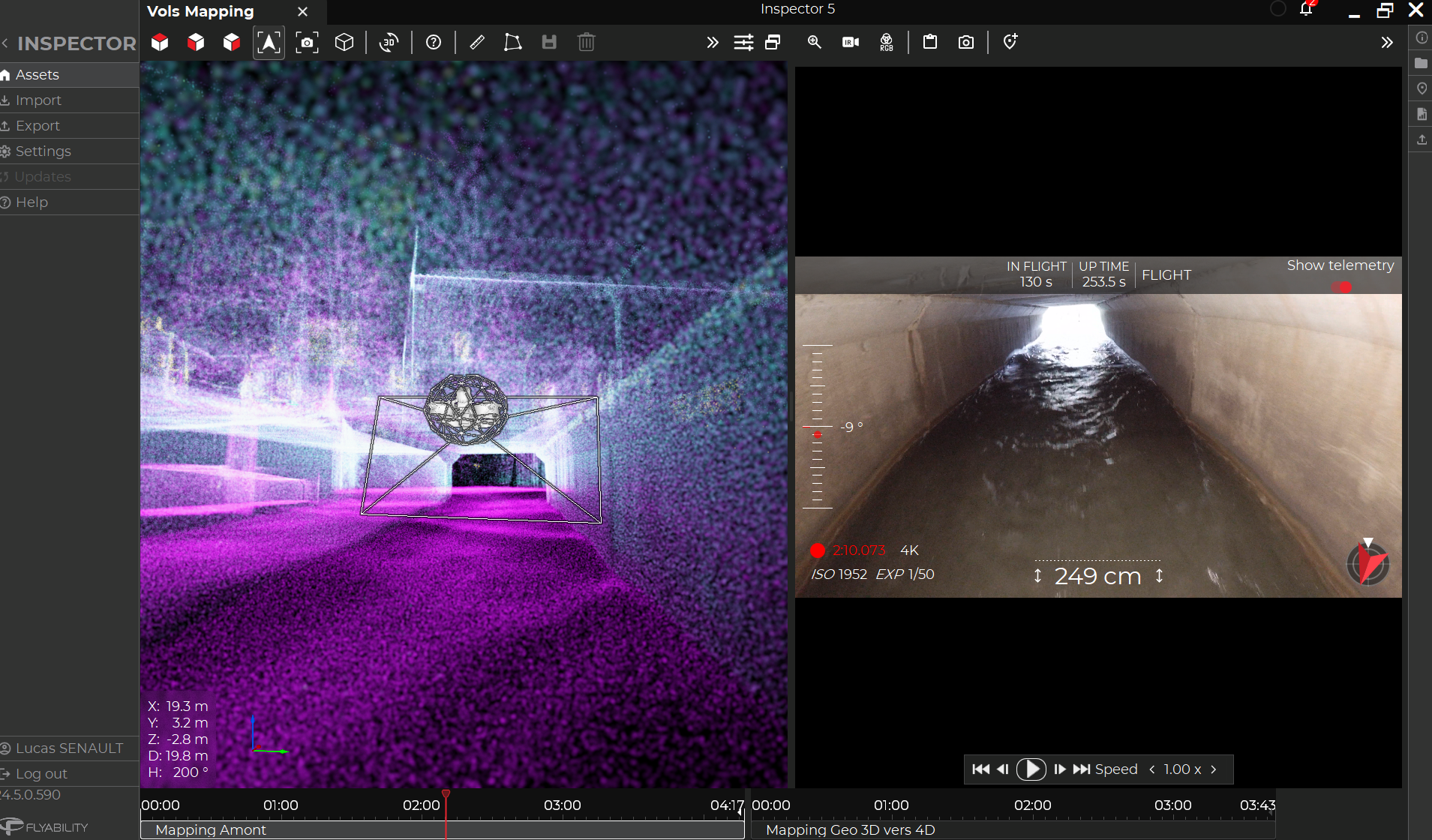

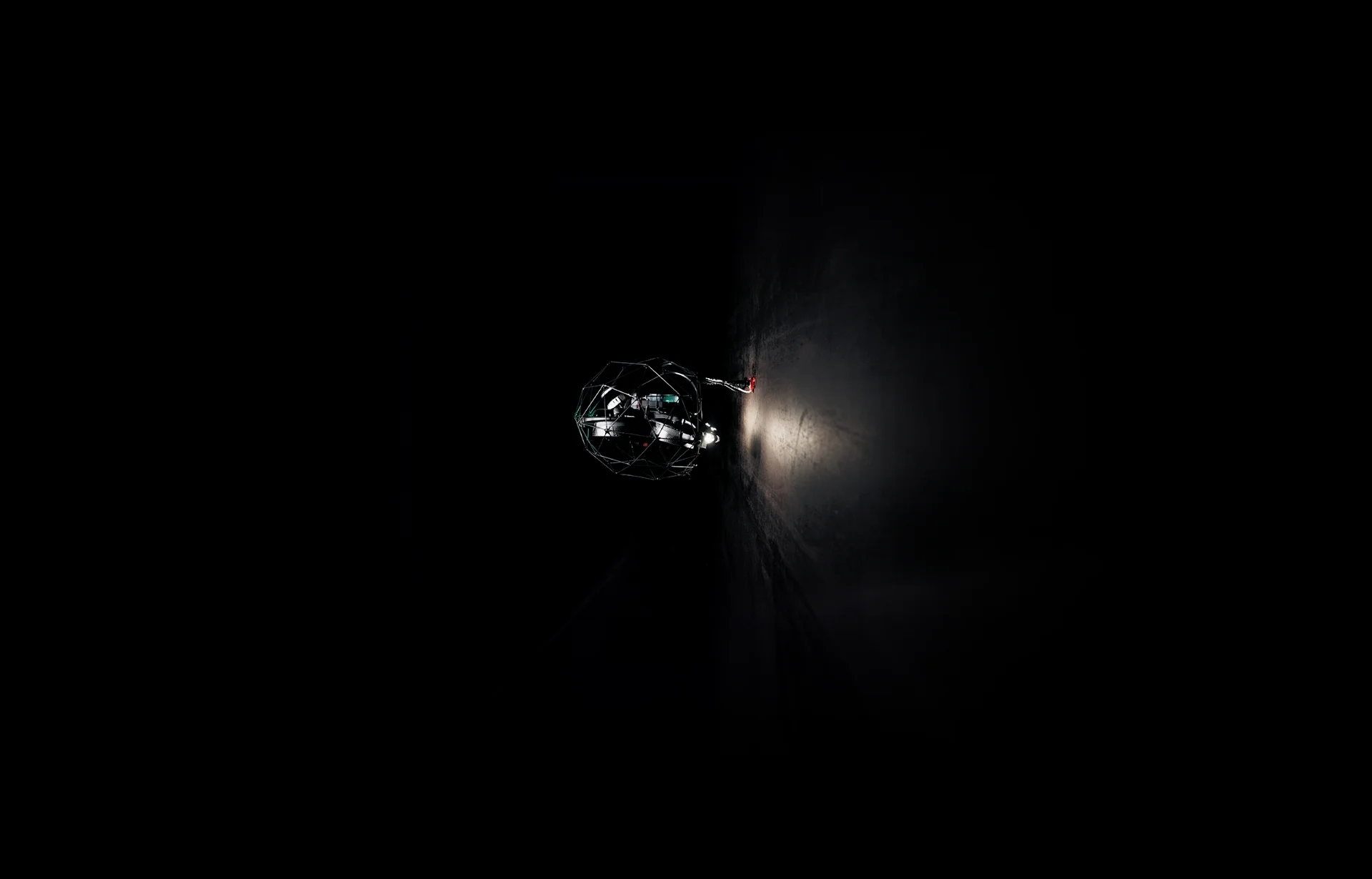

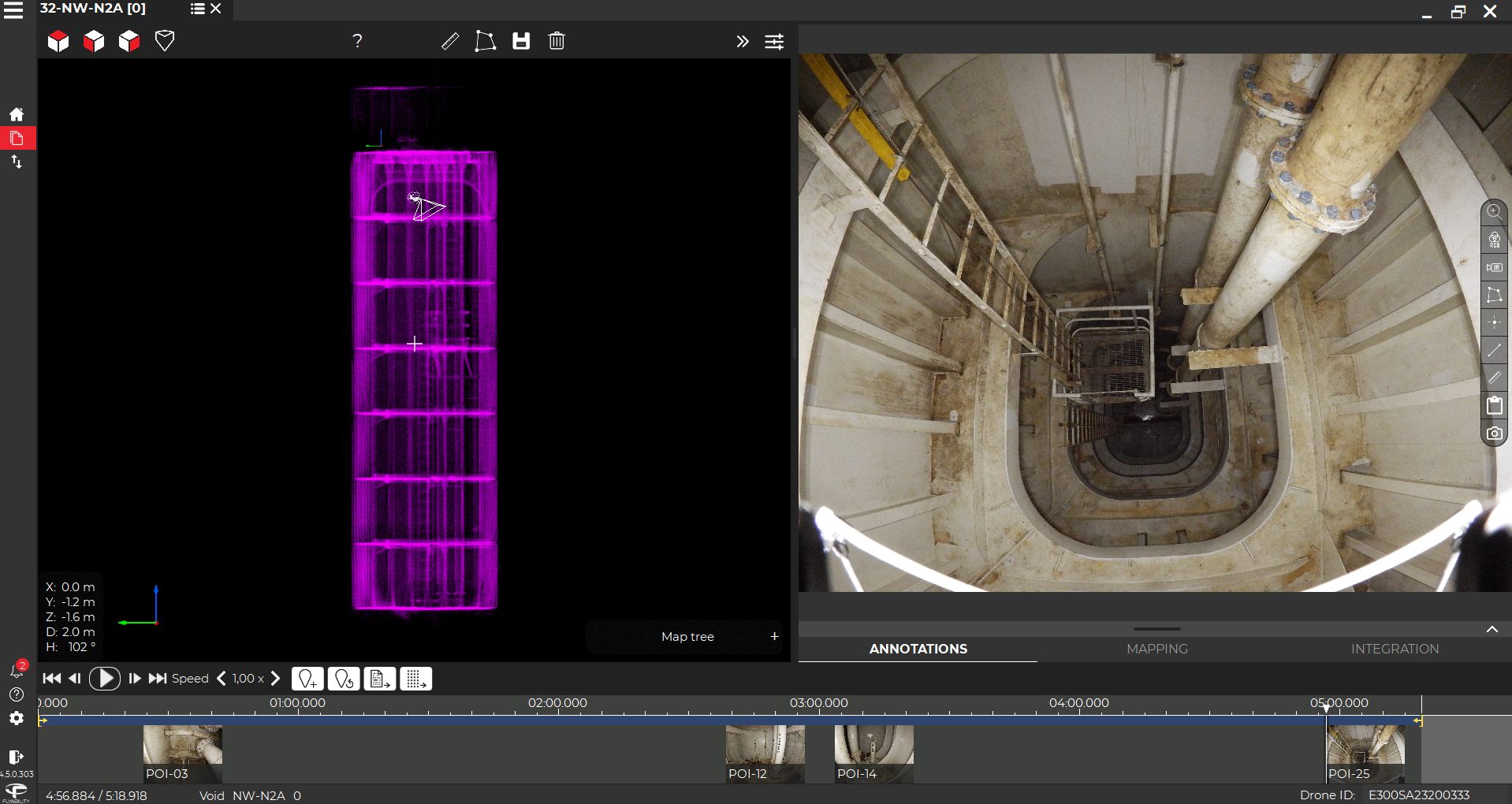

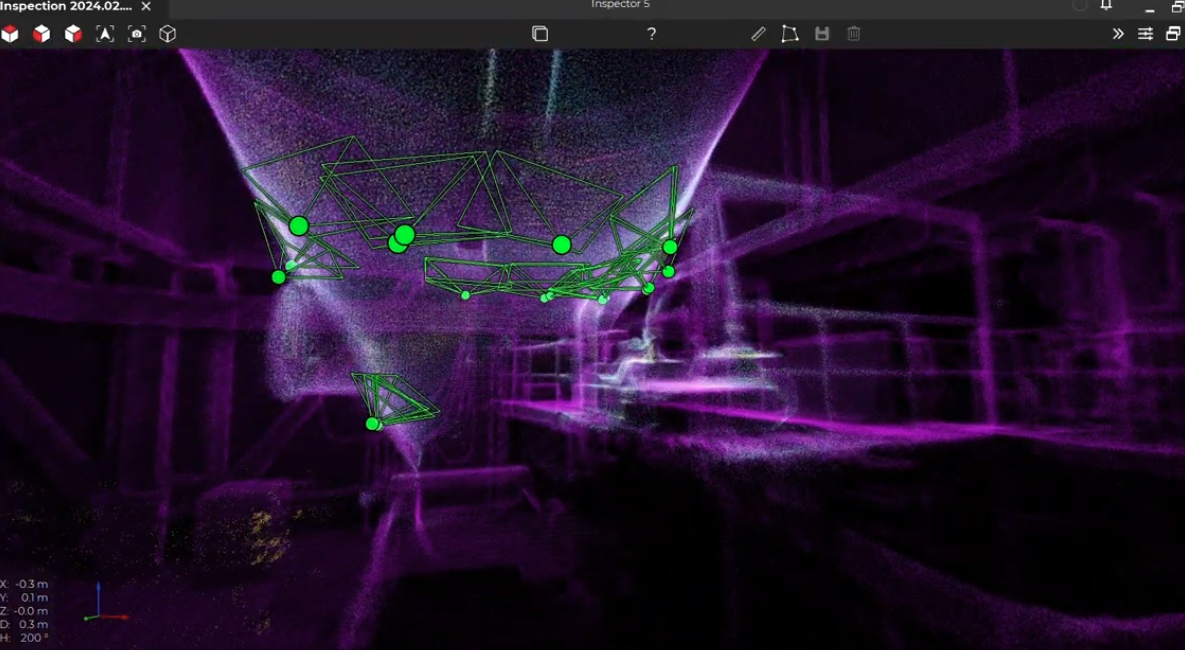

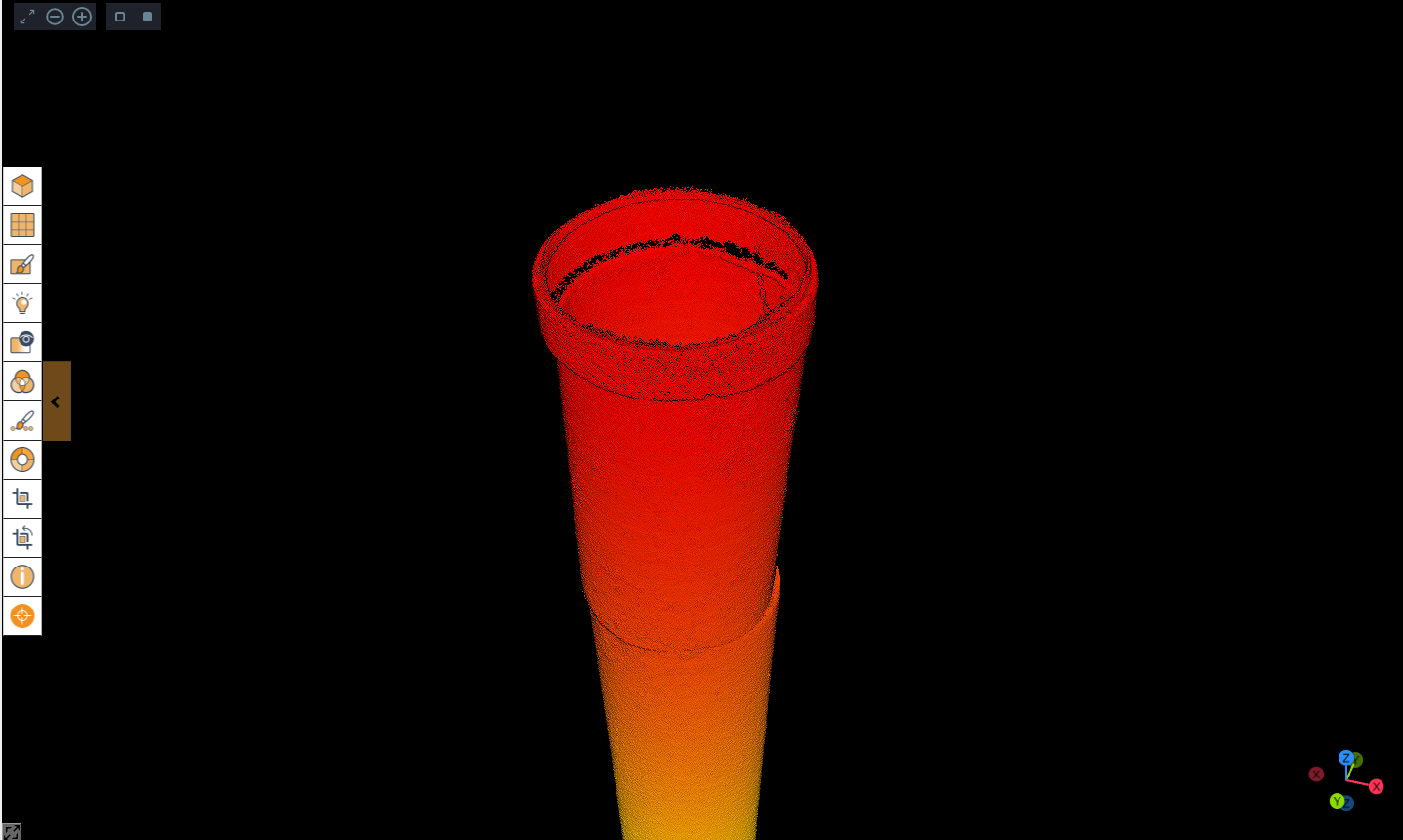

Designed for extreme conditions, Birdseye, leveraging Flyability’s ELIOS 3, inspected 2 parallel pipelines — one with a diameter of 1,800 mm and the other 1,200 mm — making it ideal for inspections:

- Unique Design: The drone’s rugged, collision-tolerant cage can withstand something and features a Smart Return-to-Home tool that brings it back to its starting point.

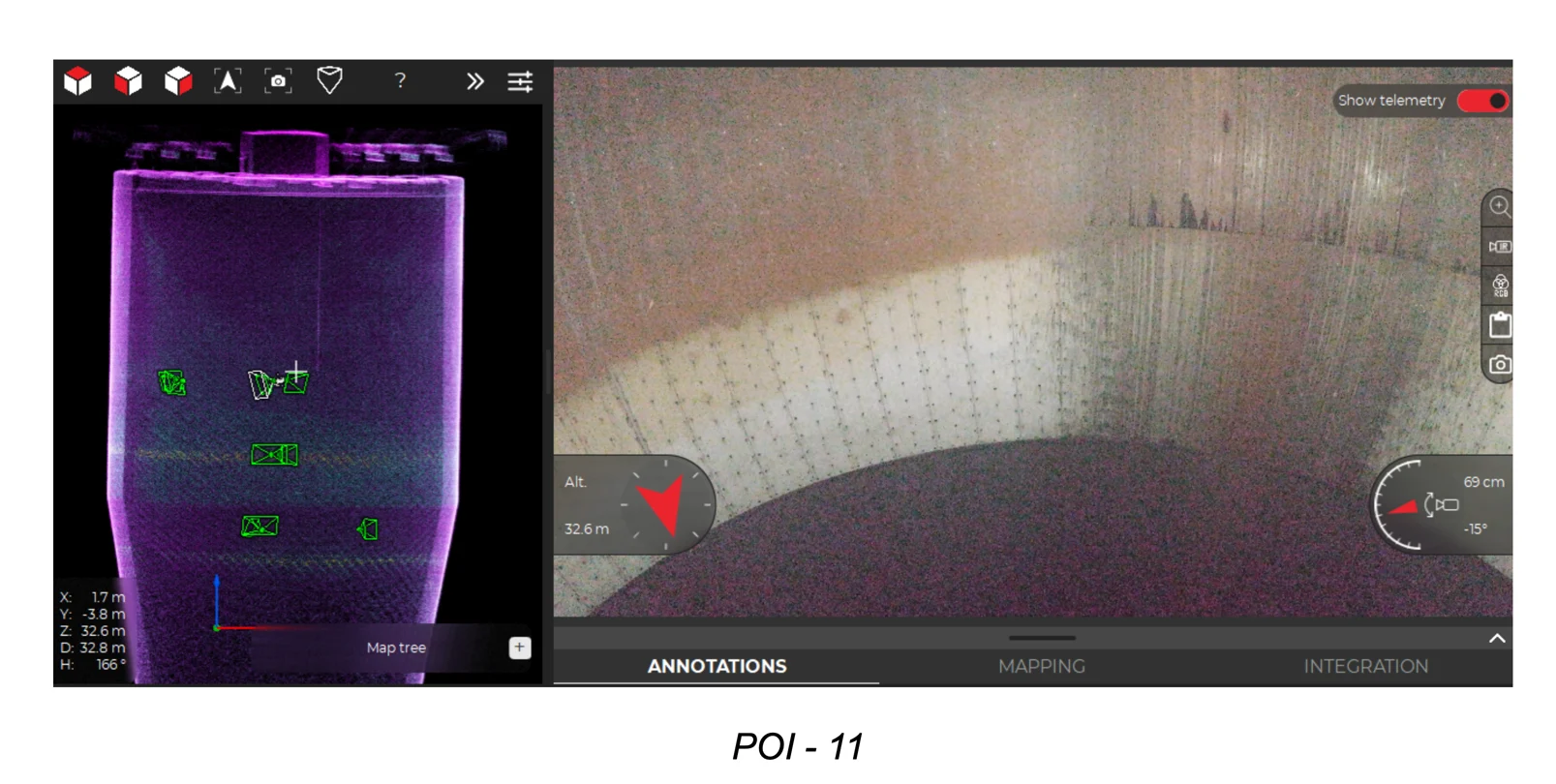

- High-Performance Payload Systems: With a 4K camera and centimeter-accurate LiDAR, Elios 3 creates precise 3D models and identifies defects with pinpoint accuracy, streamlining the repair process.

Outcome

| Parameter | Without Birdseye | With Birdseye |

|---|---|---|

| Safety | Workers had to enter drains, exposing them to biohazards, toxic gases, and falls. | Workers remained safe — no entry into drains, avoiding exposure to biohazards, gas, and falls. |

| Speed | Inspections took longer due to manual effort and post-processing. | Results delivered in real time, completed in just one day — faster than traditional methods. |

| Time Efficiency | Time-consuming prep needed (cleaning, water jetting) before inspections. | Drone entered pipes seamlessly without the need for cleaning or jetting, Saving significant amount of time. |

| Data Quality | Limited visuals due to poor lighting and restricted access. | LiDAR and 4K camera provide crystal-clear visuals and detailed spatial data in tight, dark areas. |

| Coverage | Limited pipeline coverage due to manual constraints. | Inspected 265.69 meters of pipeline with exceptional accuracy. |

Conclusion

Birdseye demonstrates how sewer systems can drastically decrease reliance on manual power, optimize safety, lessen disruption to any surrounding infrastructure, and enhance data accuracy through drone-powered inspections.

The final dataset delivered actionable insights, facilitated in strategically planning maintenance and asset management using accurate digital twins of the stormwater drains. The speed, precision, and quality of data delivered proved that the future of infrastructure assessment lies not in risking human lives, but in harnessing the power of advanced drone technology.