Challenges

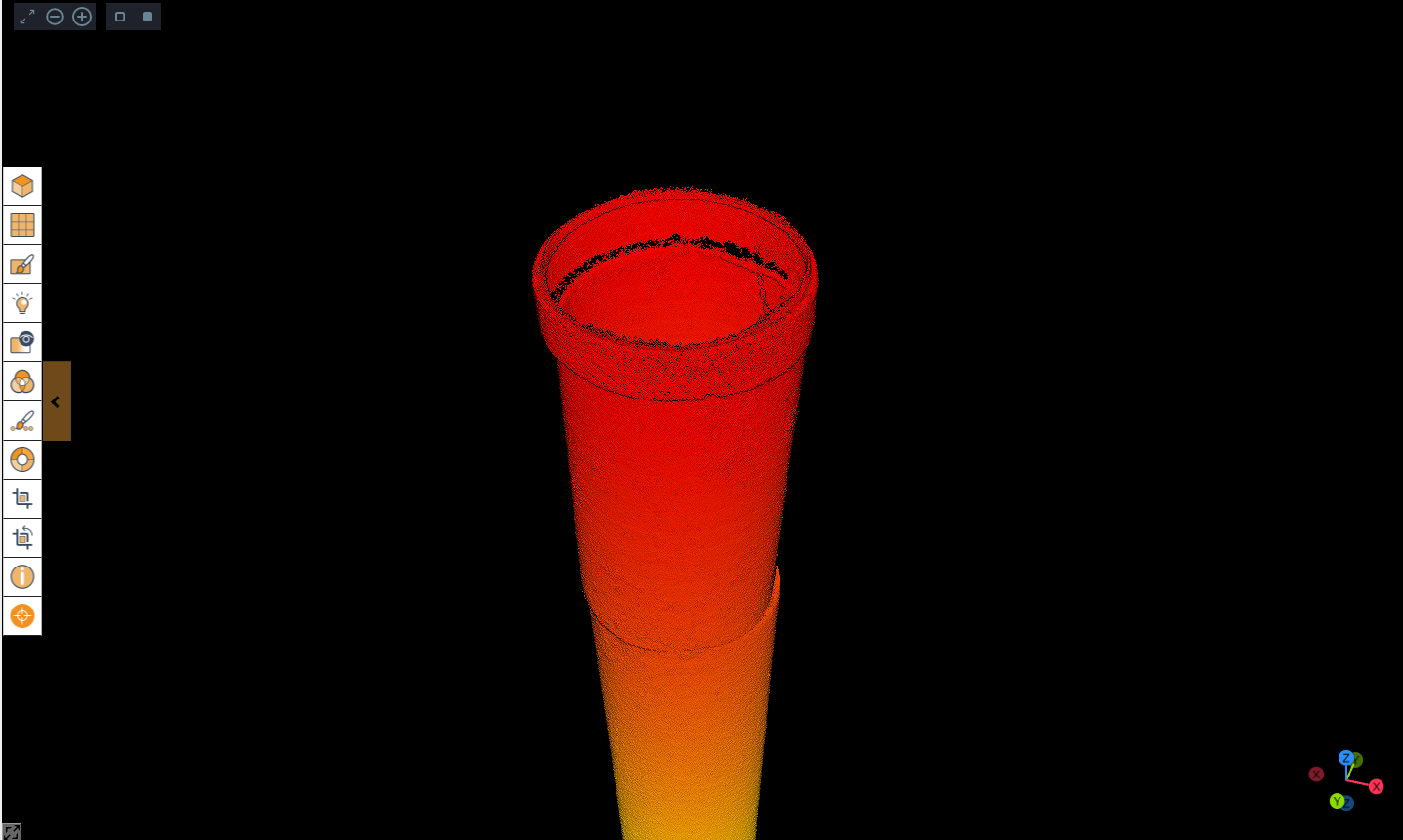

A mining company in Oman needed to inspect the interior of their 40-meter-high storage bins to check for damage to the polyethylene (PE) lining. Traditional methods required inspectors to use rope access, exposing them to dust, confined spaces, and working at height — making the process dangerous and time-consuming (10–15 days per inspection).

Solution

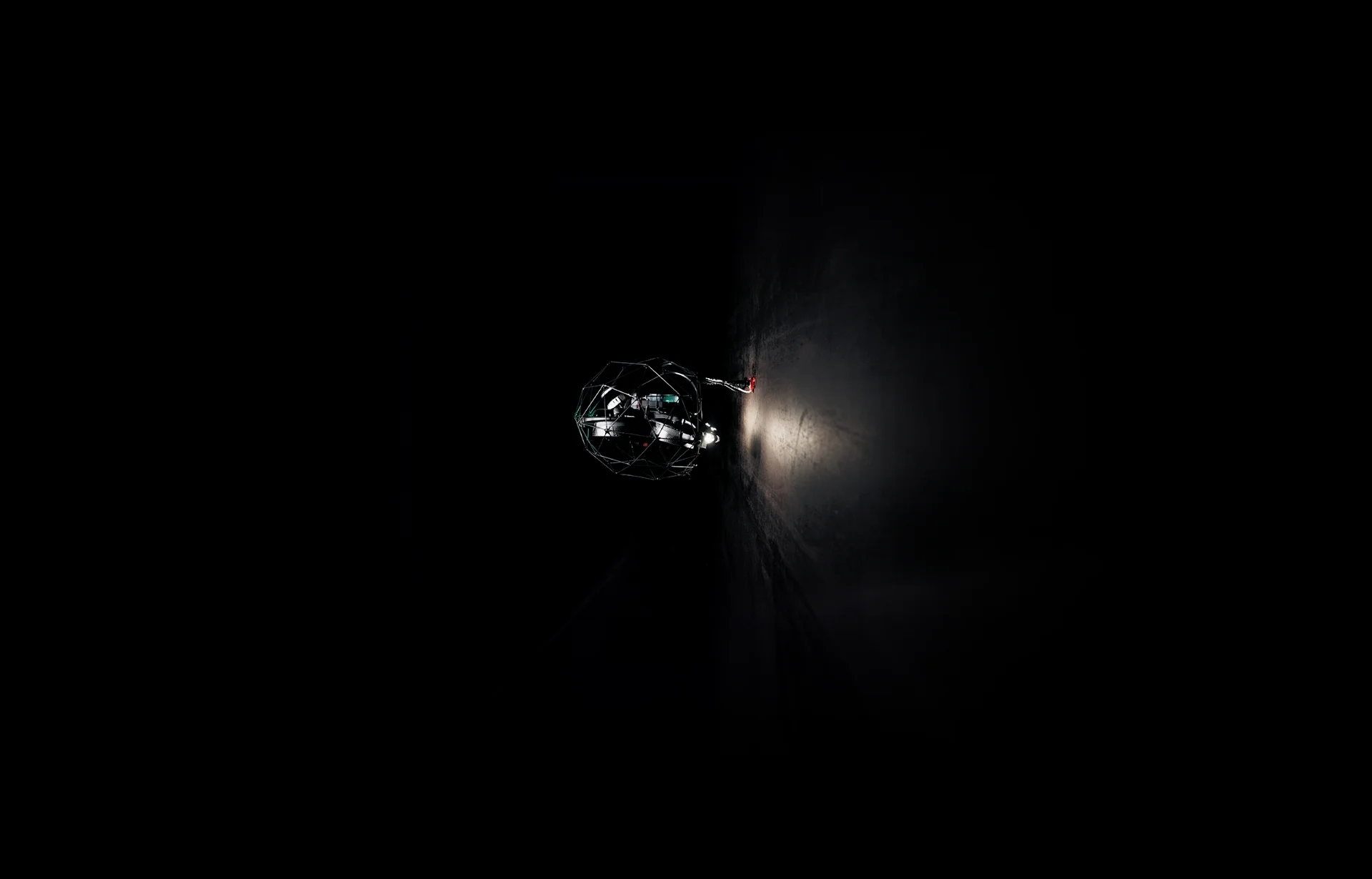

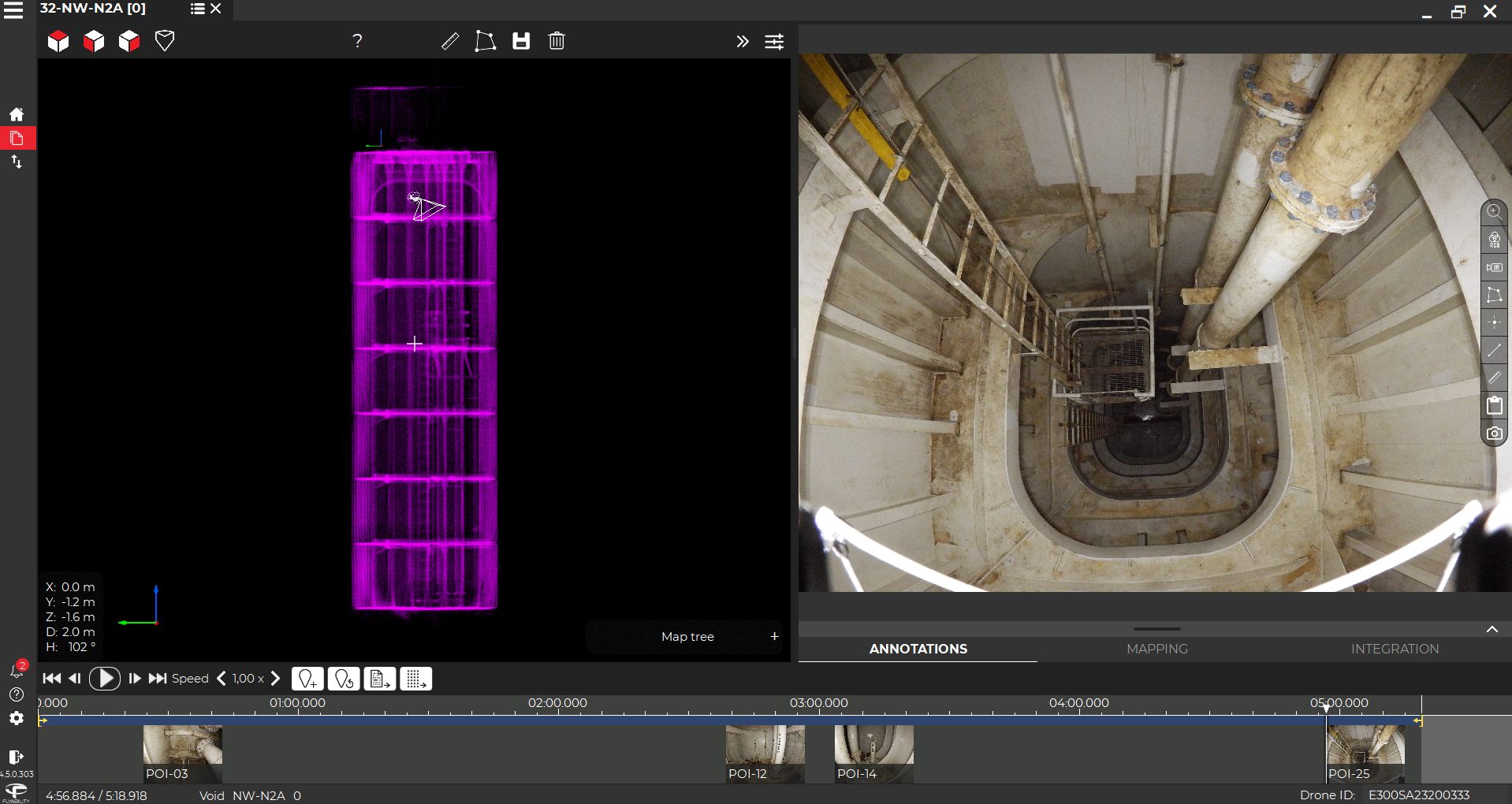

The mining company partnered with Birdseye, utilizing the Elios 3 drone for confined space inspections. The goal was to make inspections safer, faster, and more efficient.

What Changed With Elios 3

| Aspect | Traditional Method | With Elios 3 Drone |

|---|---|---|

| Time | 10–15 days per inspection | Just 4 days for all 7 bins |

| Safety | Rope access in dusty, confined spaces | No human entry needed; safer for inspectors |

| Data Quality | Manual observations | High-resolution visuals + 3D LiDAR point clouds |

| Access | Limited by human reach and visibility | Full internal access using multiple drone entry points |

How It Worked

- Flight Planning: Birdseye created custom flight plans to safely inspect all 7 storage bins.

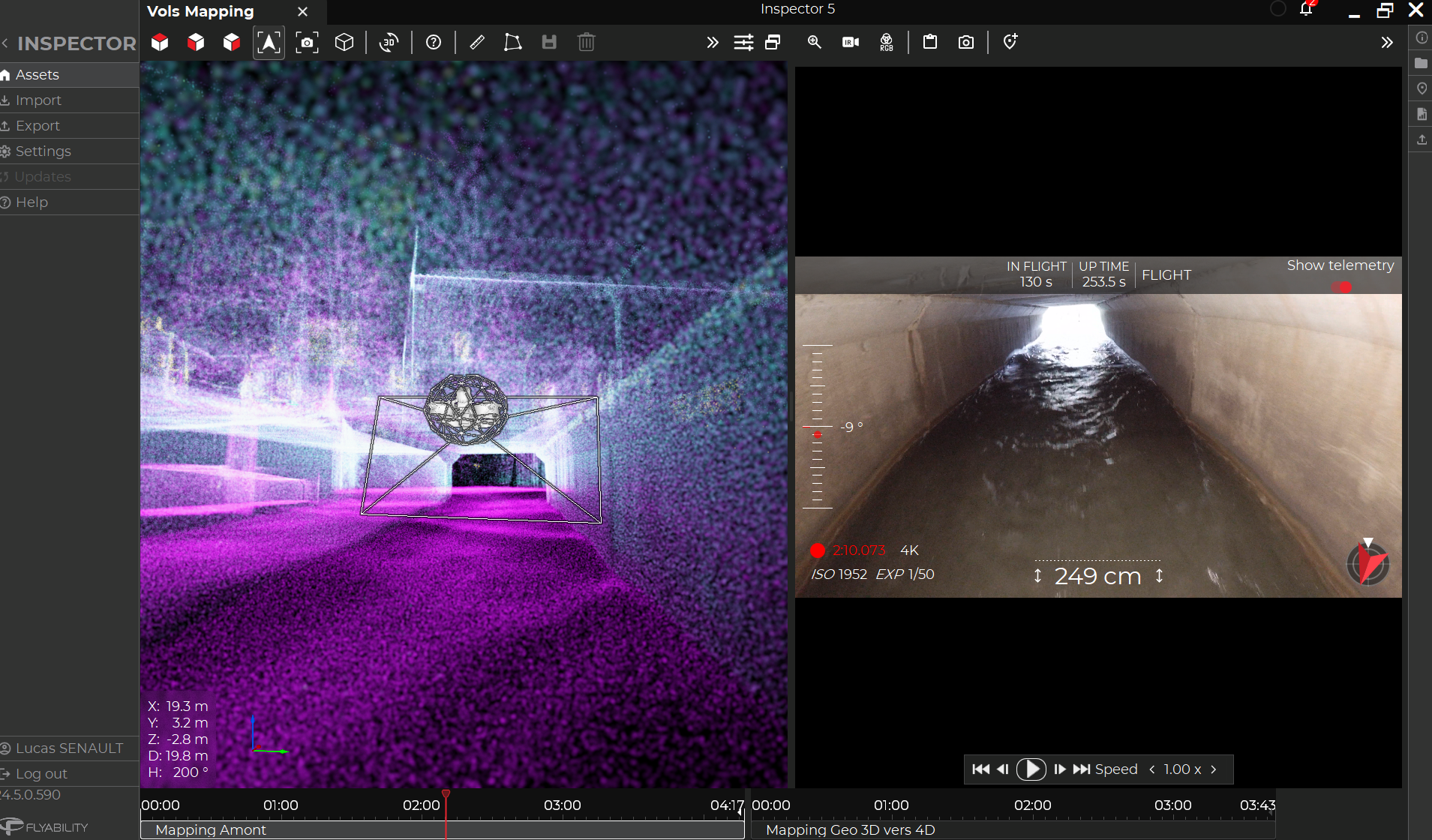

- No Entry Required: The drone flew through entry points without needing the bins to be emptied or anyone to go inside.

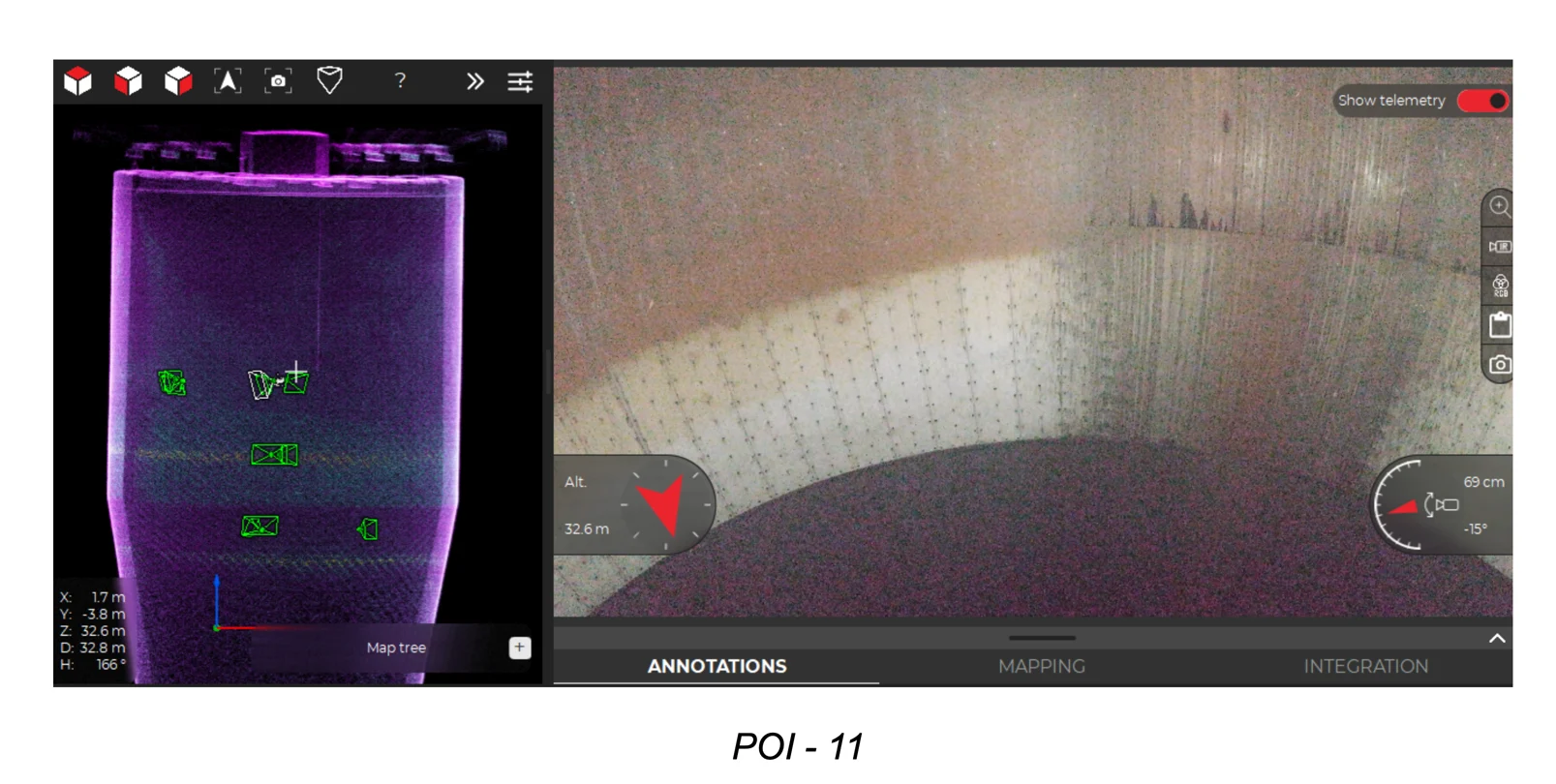

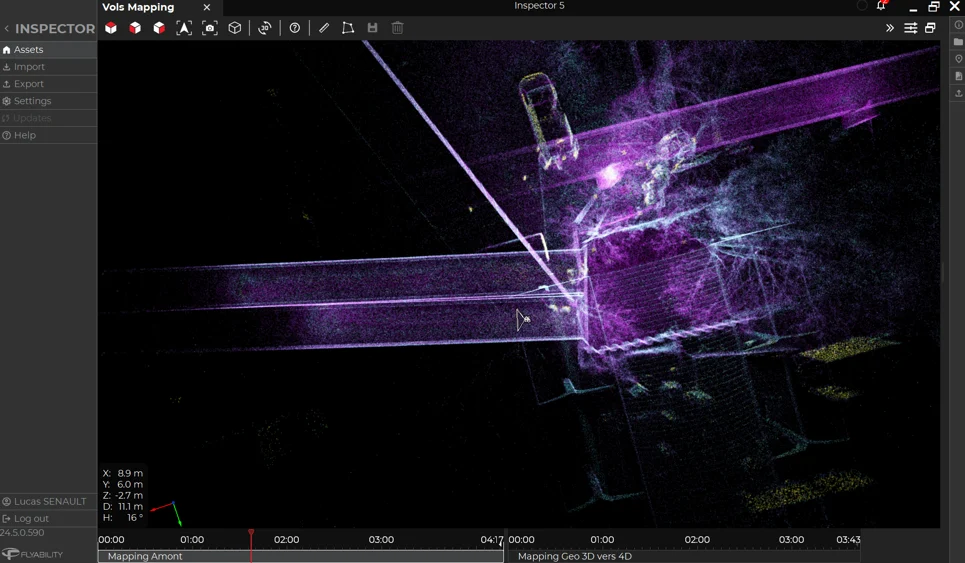

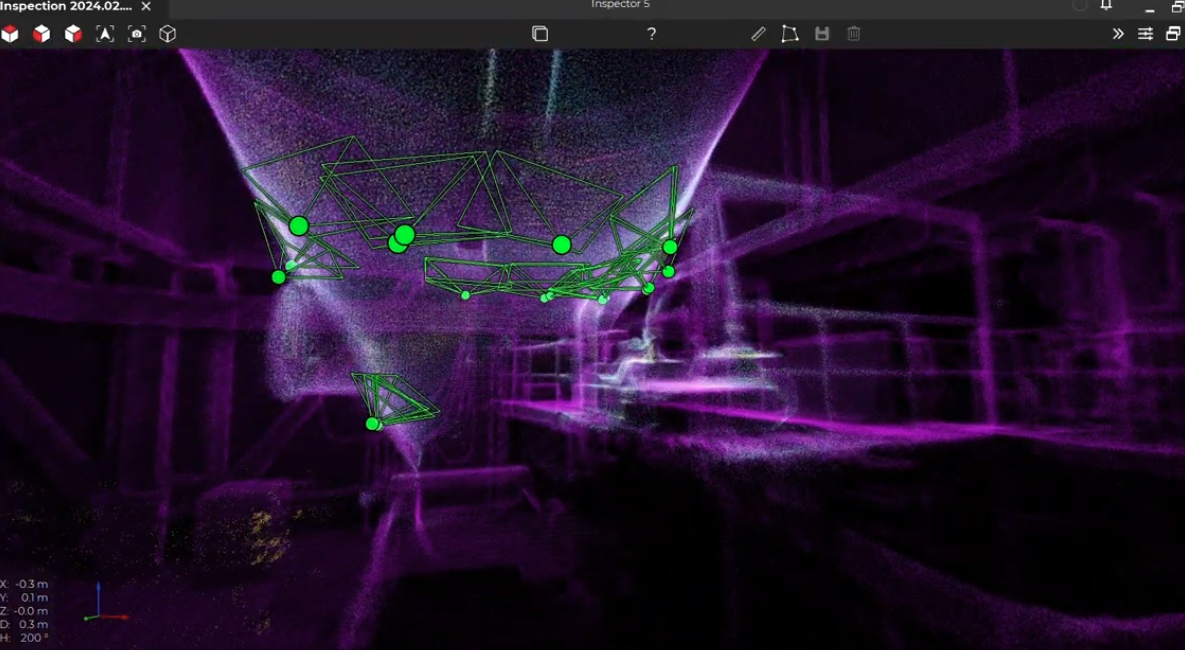

- Advanced Data Collection: Elios 3 captured both visual and LiDAR data in a single flight.

- Smart Reporting: The team generated detailed 3D models with geolocated points of interest, helping the client easily identify and plan maintenance needs.

Results

- 80% Faster Inspections

- Zero Human Entry or Rope Work

- Detailed 3D Reporting

- Improved Communication Between Teams

The client was impressed by the precision and speed. They could clearly see where issues were inside the bins and plan repairs without guesswork.

Conclusion

By utilizing Birdseye’s advanced drone technology, the mine set a new standard for safety and efficiency in storage bin inspections — paving the way for smarter and safer mining operations across the region.