Pushing the Limits: Radiation Testing at Energy Site

Can a drone operate in extreme radiation? That’s the question the client asked. In a groundbreaking test, the drone was exposed to radiation levels as high as 10,000 R/h to assess its resilience for use in a high-risk nuclear decommissioning project.

Project Context: The Calcine Retrieval Challenge

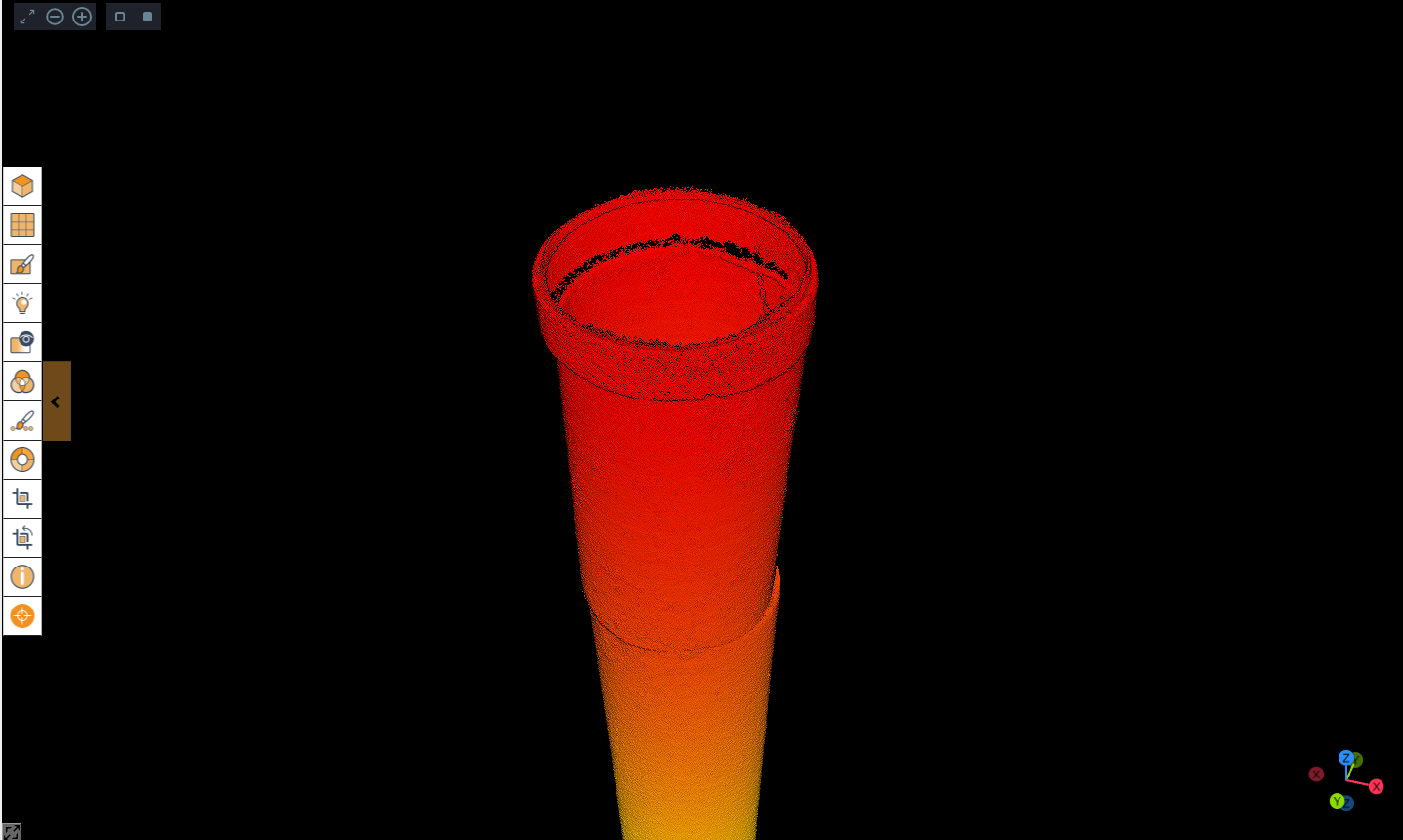

The client’s Calcine Retrieval Project (CRP) aims to safely extract and transfer several hundred cubic meters of calcine, a highly radioactive byproduct from spent nuclear fuel. This material has been stored underground for over 60 years.

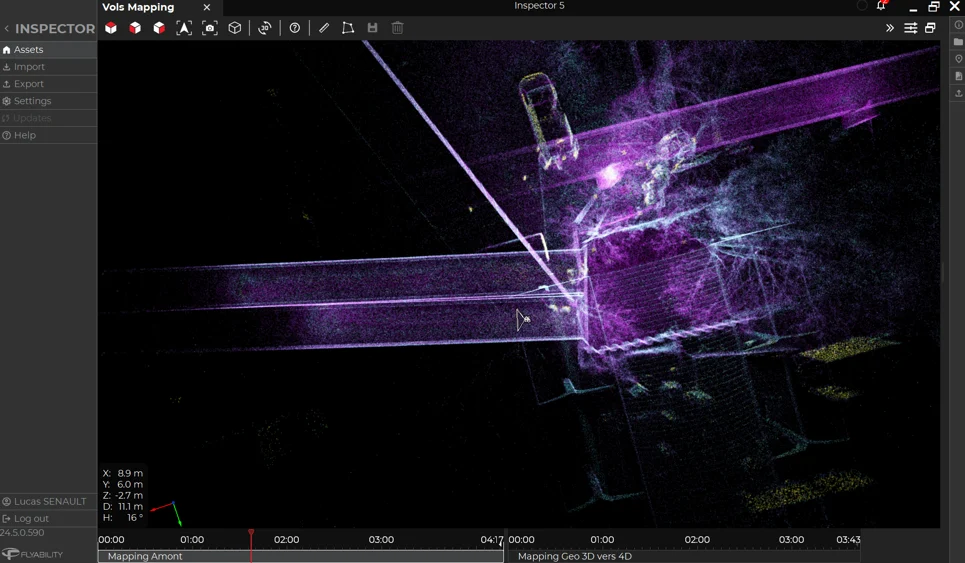

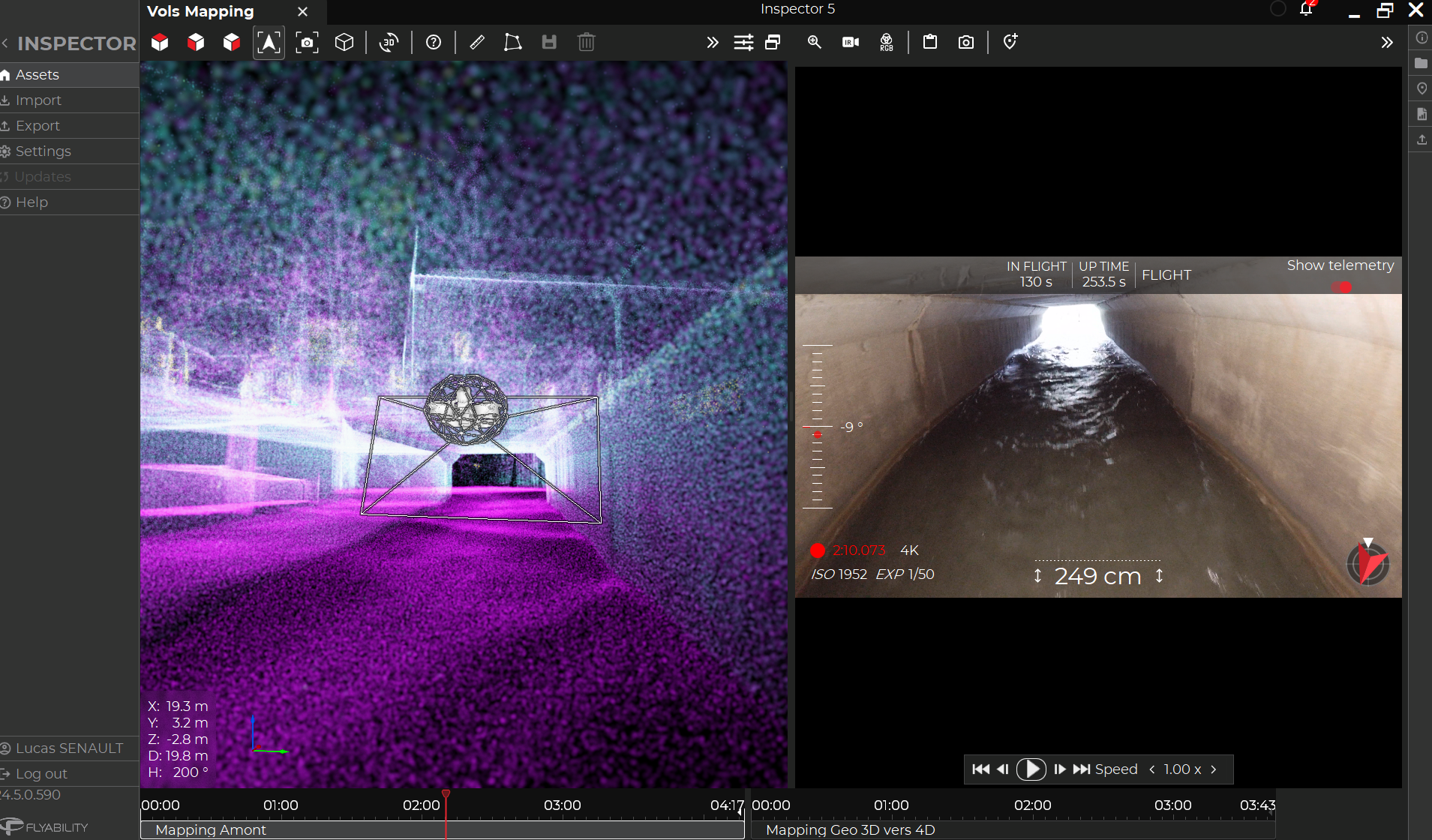

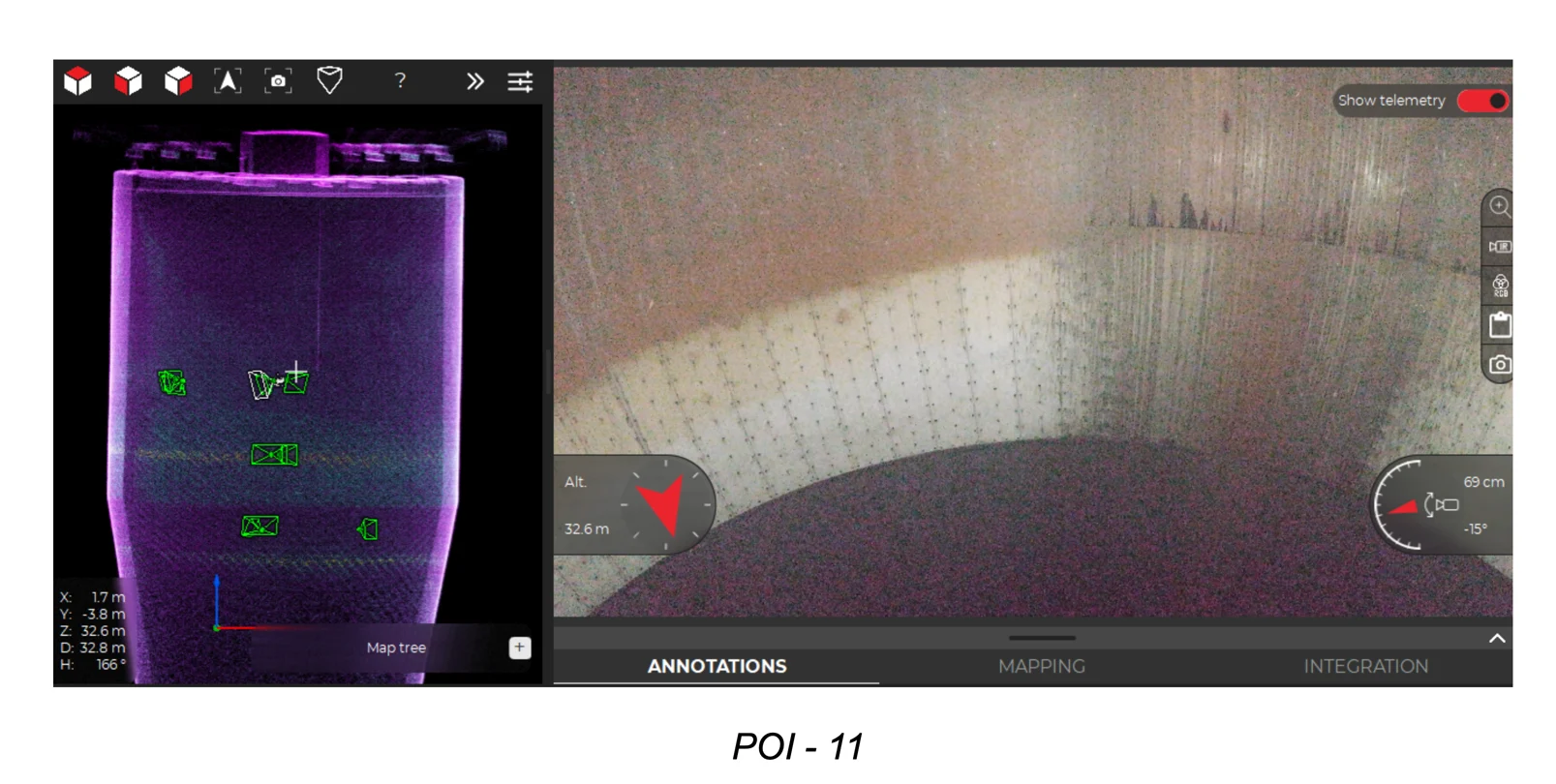

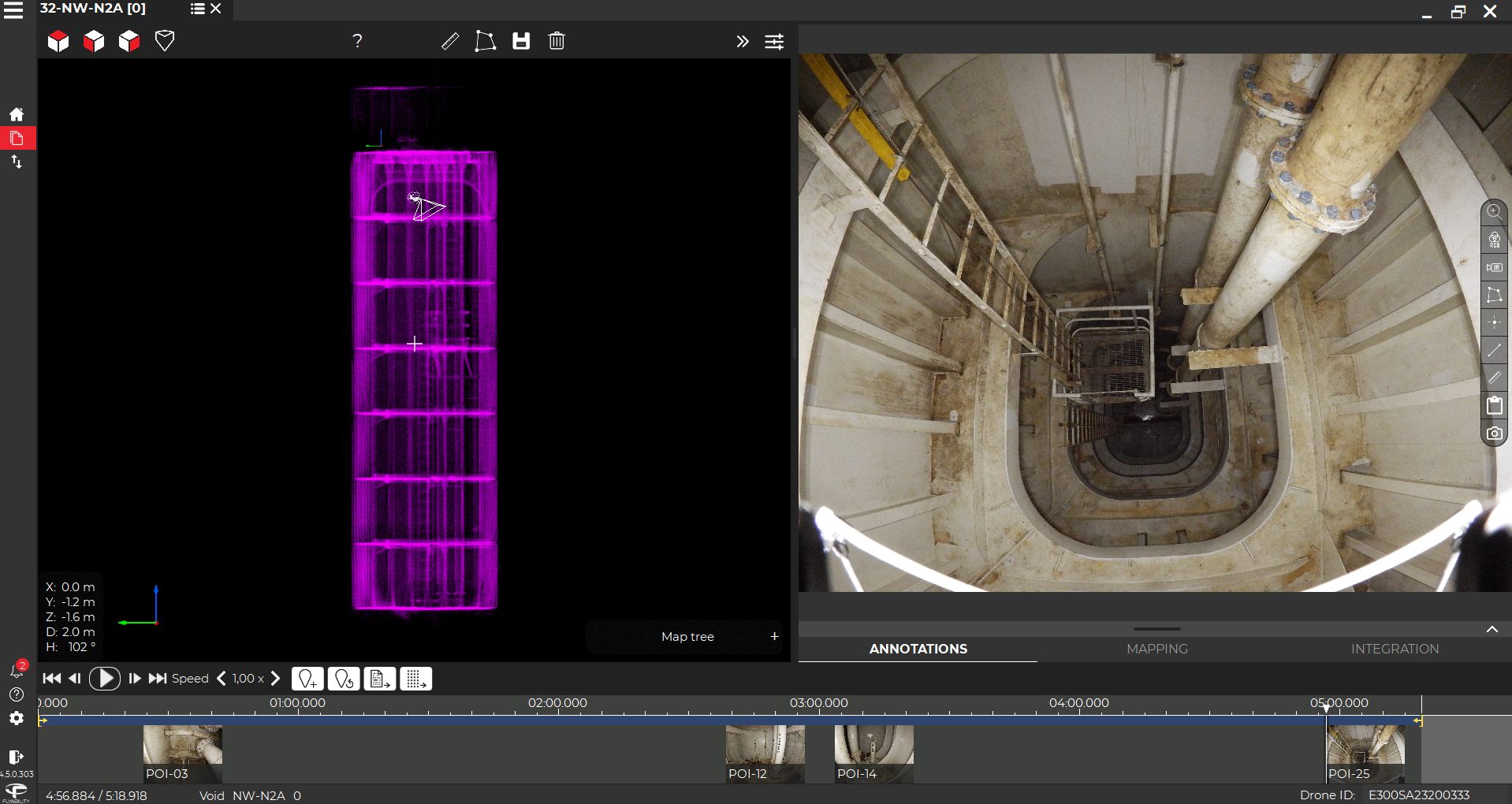

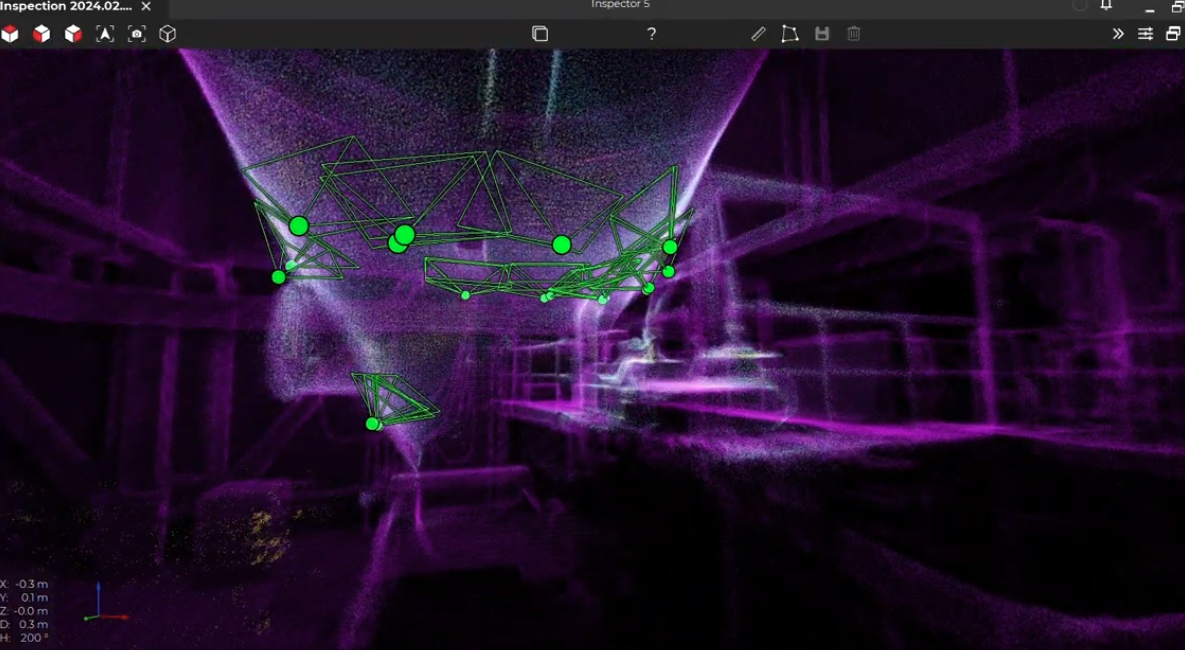

To retrieve it, the client developed a robotic method involving drilled access points, welded ports, and pneumatic removal. But before implementation, they needed a detailed 3D inspection of the vault’s internal layout — identifying obstructions like structural beams, conduits, and vent lines.

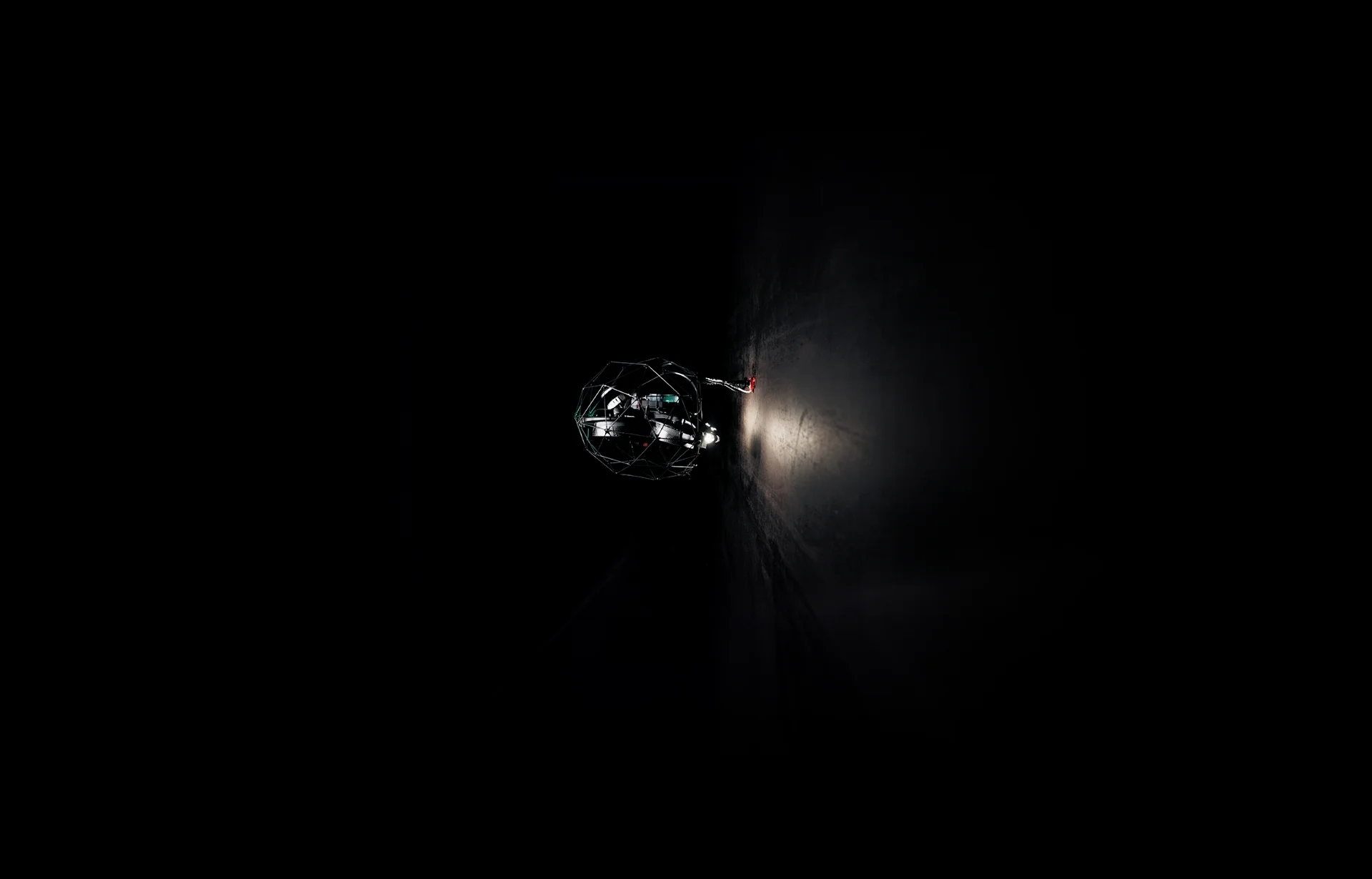

After evaluating options, Birdseye’s indoor inspection drone came into the picture. Why? Because it’s built for confined space navigation, nuclear-grade inspection, and LiDAR-based 3D modeling. But one critical question remained:

Could our drones survive the vault’s intense radiation long enough to complete the mission?

Radiation Testing: Objectives and Setup

The client and its engineering team conducted rigorous radiation tolerance tests using a 450 keV X-ray generator to simulate radiation fields equivalent to those inside the calcine vault.

Testing Goals:

- Confirm operational capability in a 1,000 R/h radiation field

- Ensure continued functionality after a 1,000 R total absorbed dose

How It Was Done:

- Birdseye Drone was flown repeatedly in controlled radiation zones.

- Dosimetry devices were attached to the drone to measure precise exposure.

- All onboard systems — including flight control, visual camera, LiDAR sensor, lighting, gimbal, and transmitter — were monitored in real time.

Key Results: Birdseye Exceeded Expectations

- Operational in radiation fields up to 10,000 R/h (10× the initial requirement)

- Remained functional after an accumulated dose of ~4,000 R (4× the goal)

- Completed 19 test flights under varying levels of radiation exposure

- All critical systems — LiDAR, camera, transmitter, gimbal, lights — performed as intended

To put the exposure in perspective: 4,000 R is roughly 800 times greater than the annual radiation limit permitted for human workers in regulated environments.

Implications for Nuclear Inspection and Decommissioning

The success of this test demonstrates the Elios 3’s value in high-radiation inspections, offering a new standard for remote inspection in nuclear facilities, radioactive waste storage sites, and decommissioning operations.

The drone’s durability ensures accurate data collection in environments where traditional tools — and humans — cannot operate safely.

This capability opens the door to:

- Reduced personnel risk

- Accelerated inspection workflows

- High-resolution 3D data from hazardous environments