Overview

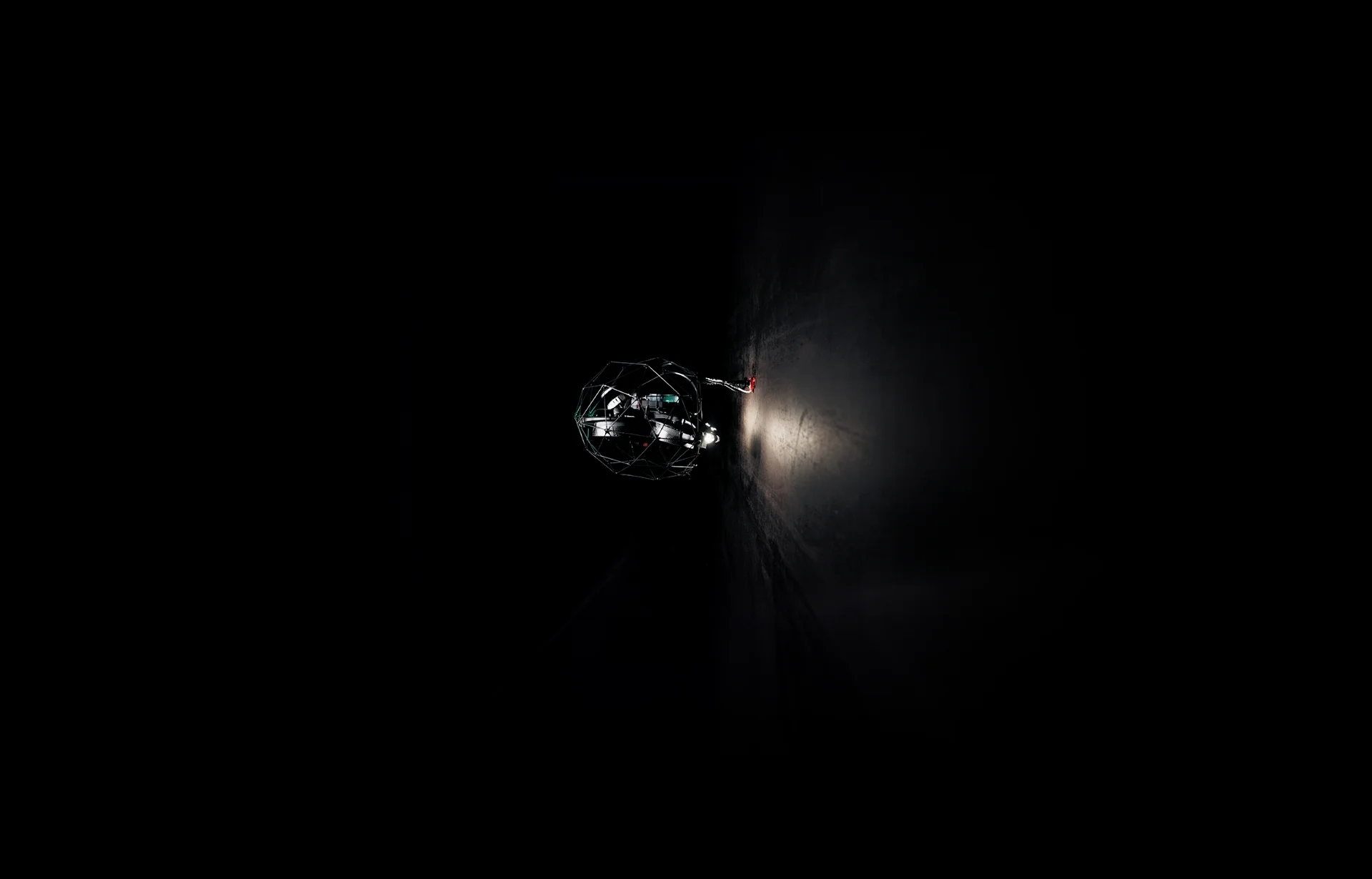

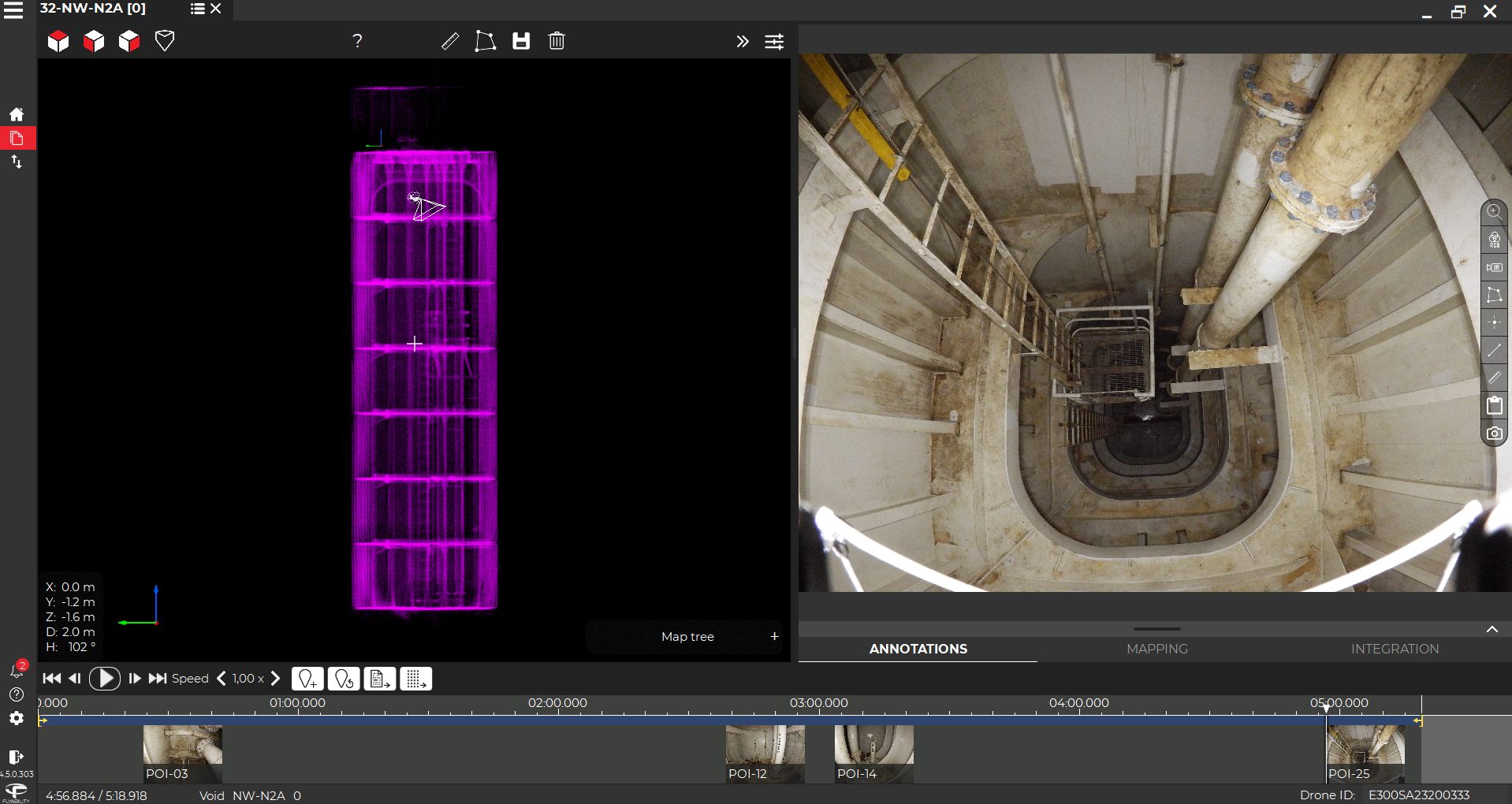

A unique simulation mine (a tunnel built in a campus basement) was built to train students and test mining technologies in a controlled environment. This tunnel had been used to operate advanced tools like Boston Dynamics’ Spot robot and Birdseye equipped with Flyability’s Elios 3 drone.

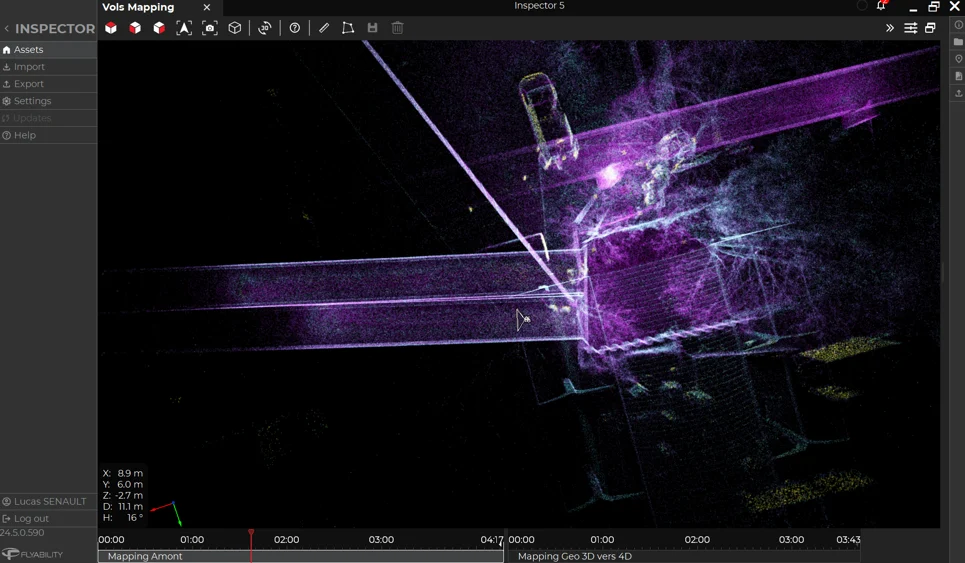

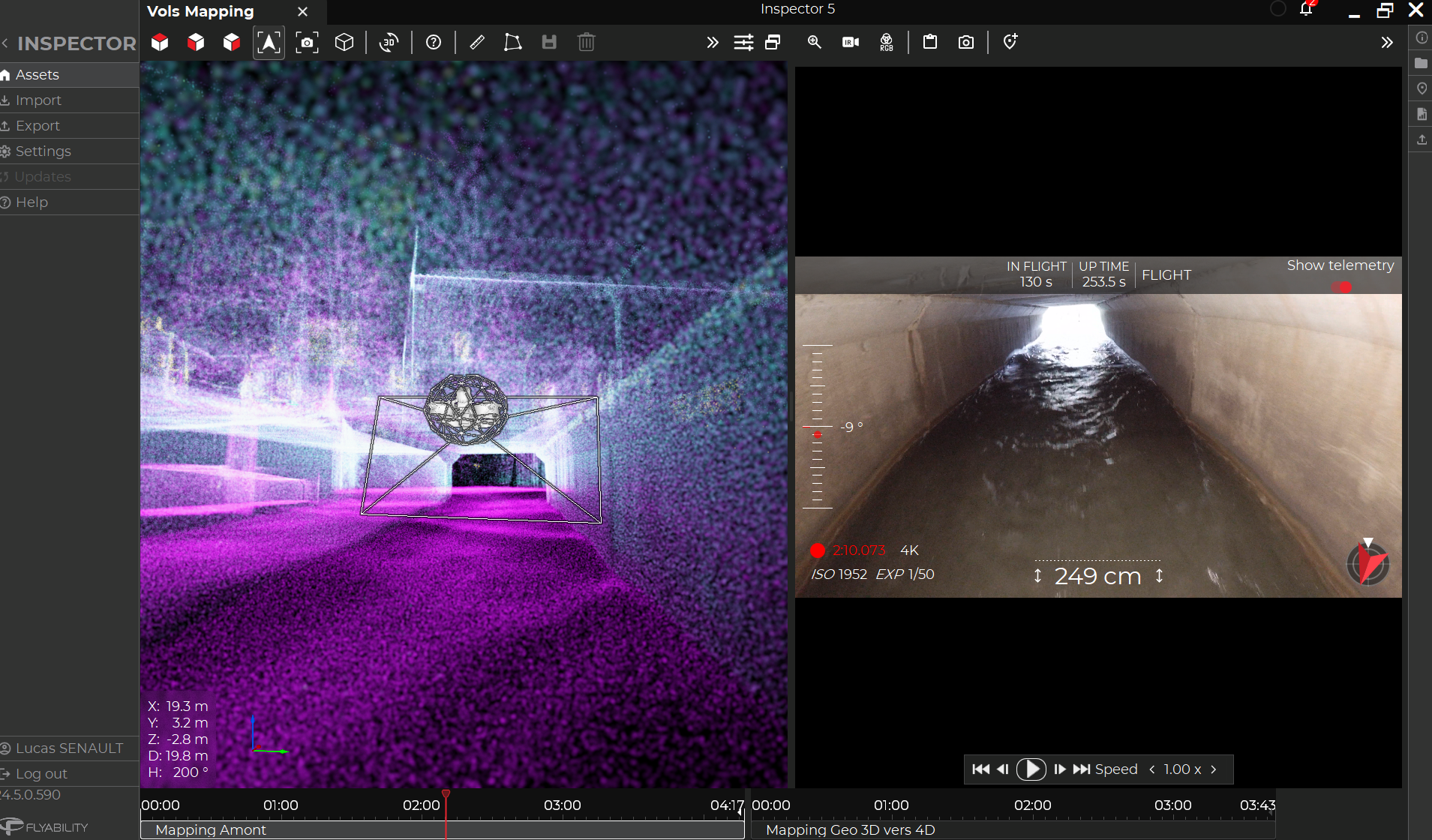

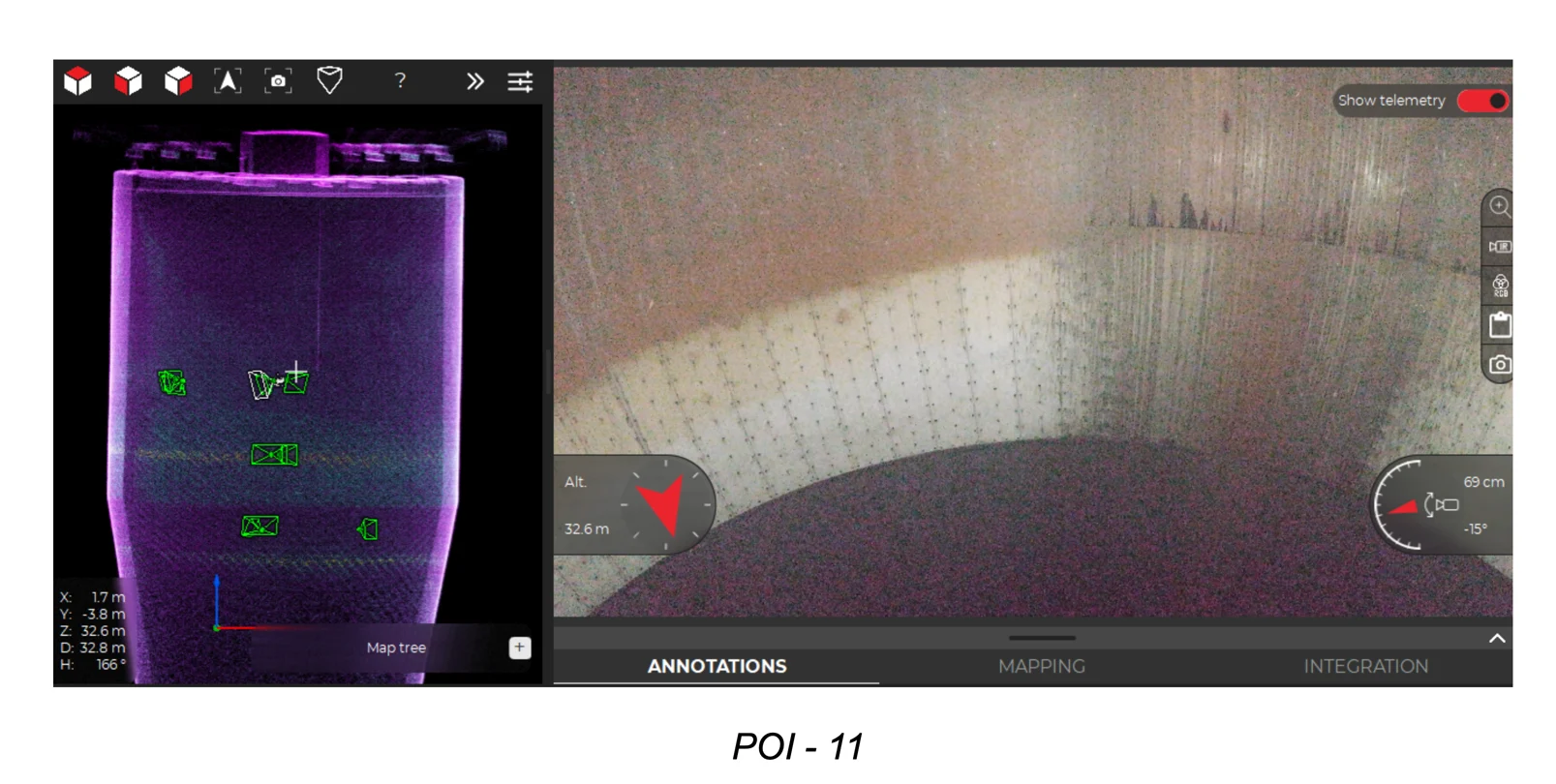

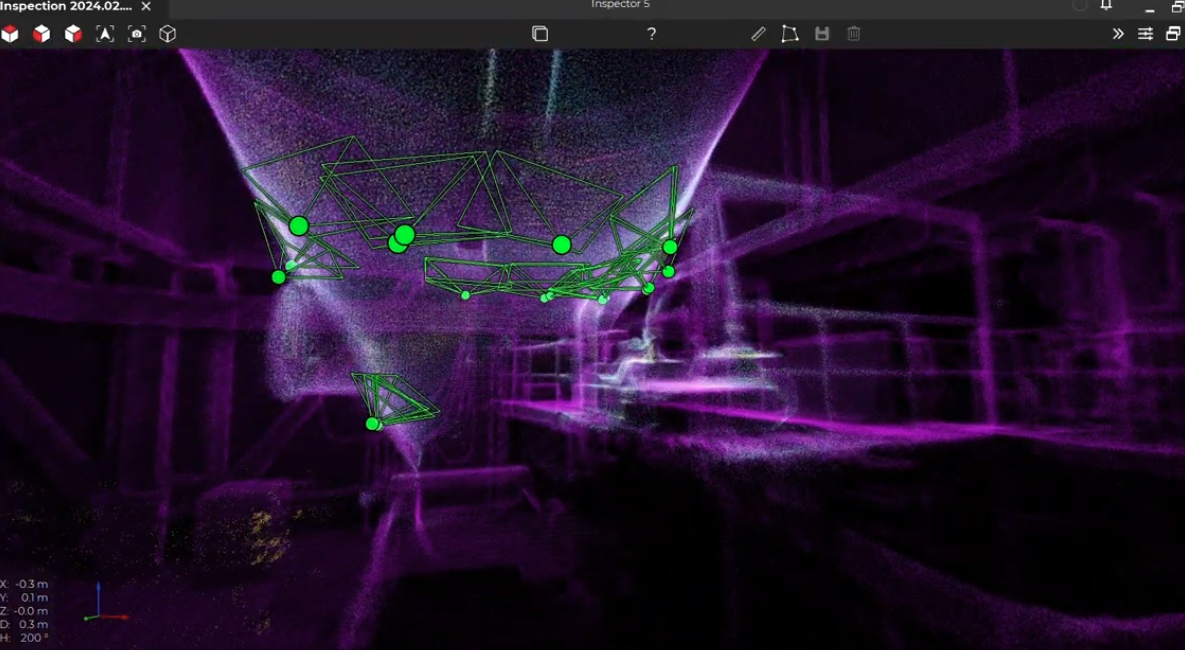

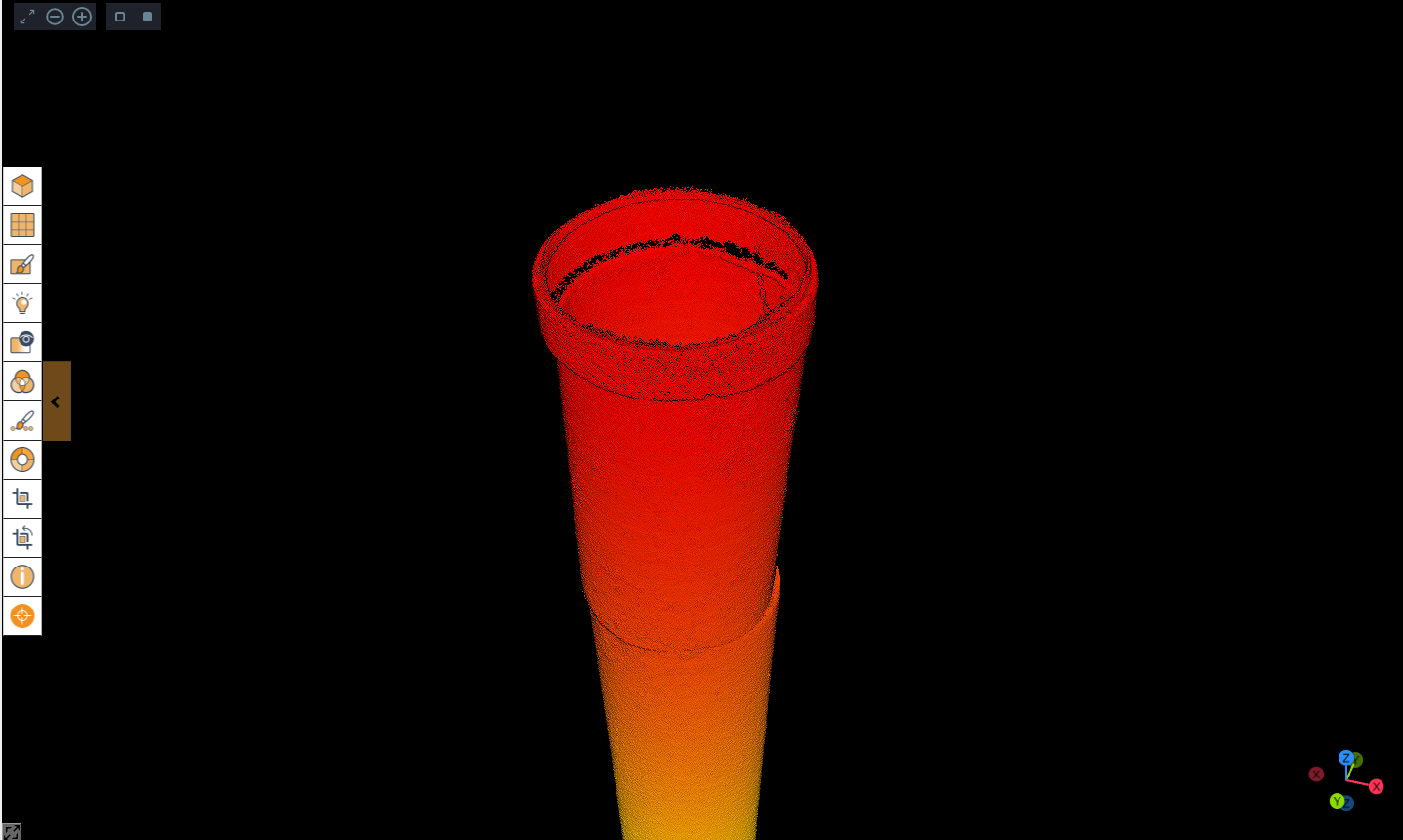

Though drones were already in use for inspection processes, the Elios 3, equipped with a LiDAR sensor, has proven especially valuable for underground inspections and 3D mapping of confined or dangerous areas.

Challenges

- Safety: Safety risks, lack of training for streamlined drone operation, and hazardous environments posed challenges.

- Regulatory Compliance: South Africa’s stringent drone policies require certified pilots and legal licenses.

- Lack of Training: Drone operators lacked technical training, hampering efficiency and increasing risks.

- Visibility Issues: Underground heat, dust, and poor ventilation reduce visibility to under 2 meters—making traditional inspection difficult.

- Technology and Trust: Outdated drones lacked stability, while trust in drone-generated data is still growing among engineers and surveyors.

Solution

The rotatable camera in Elios 3 was used to pinpoint survey pegs placed along the overhead and lateral surfaces of the excavation. The Elios 3, equipped with a LiDAR sensor, has proven especially valuable for underground inspections and 3D mapping of confined or dangerous areas.

Additionally, a virtual reality platform was developed alongside the tunnel, incorporating simulation tools for drilling and blasting training.

Outcomes

- Advanced Mapping & Spatial Awareness

- Enhanced Navigation & Operational Safety

- Hazard Detection and Risk Mitigation

- Productivity and Operational Efficiency

Conclusion

Birdseye, using the Elios 3 equipped with LiDAR, enables safer, more accurate, and efficient inspections in the harshest mining environments. Whether mapping underground voids, inspecting ore pass hangups, or identifying early geological risks, LiDAR transforms Elios 3 into a mission-critical asset—one that protects people, preserves productivity, and delivers unparalleled situational awareness in areas where visibility and safety are compromised.