Overview

At cement plants, inspections are crucial for maintaining operational efficiency and ensuring asset integrity. However, traditional inspection methods are time-consuming, risky, and labor-intensive—often involving scaffolding, rope access, and extended shutdowns.

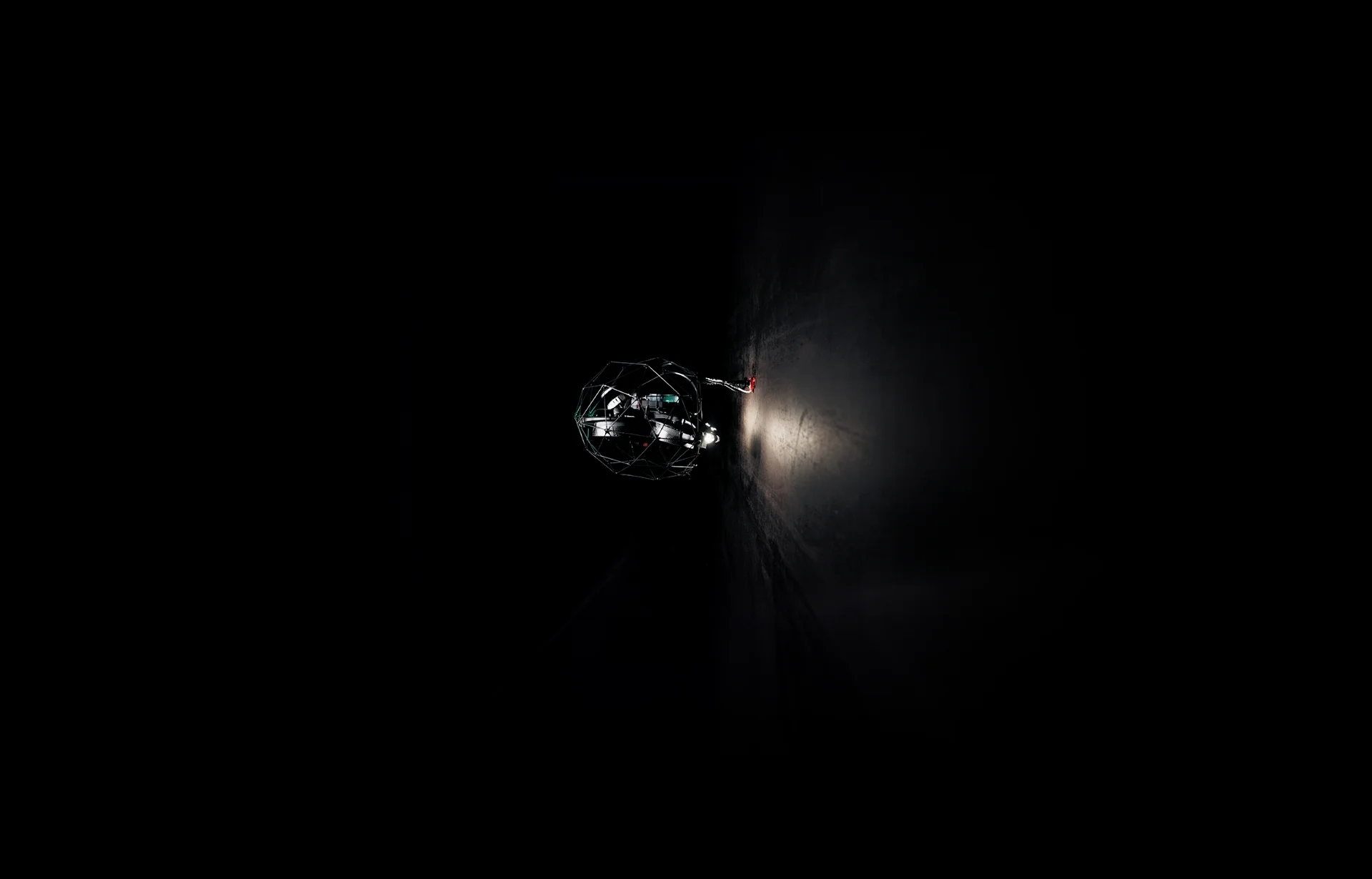

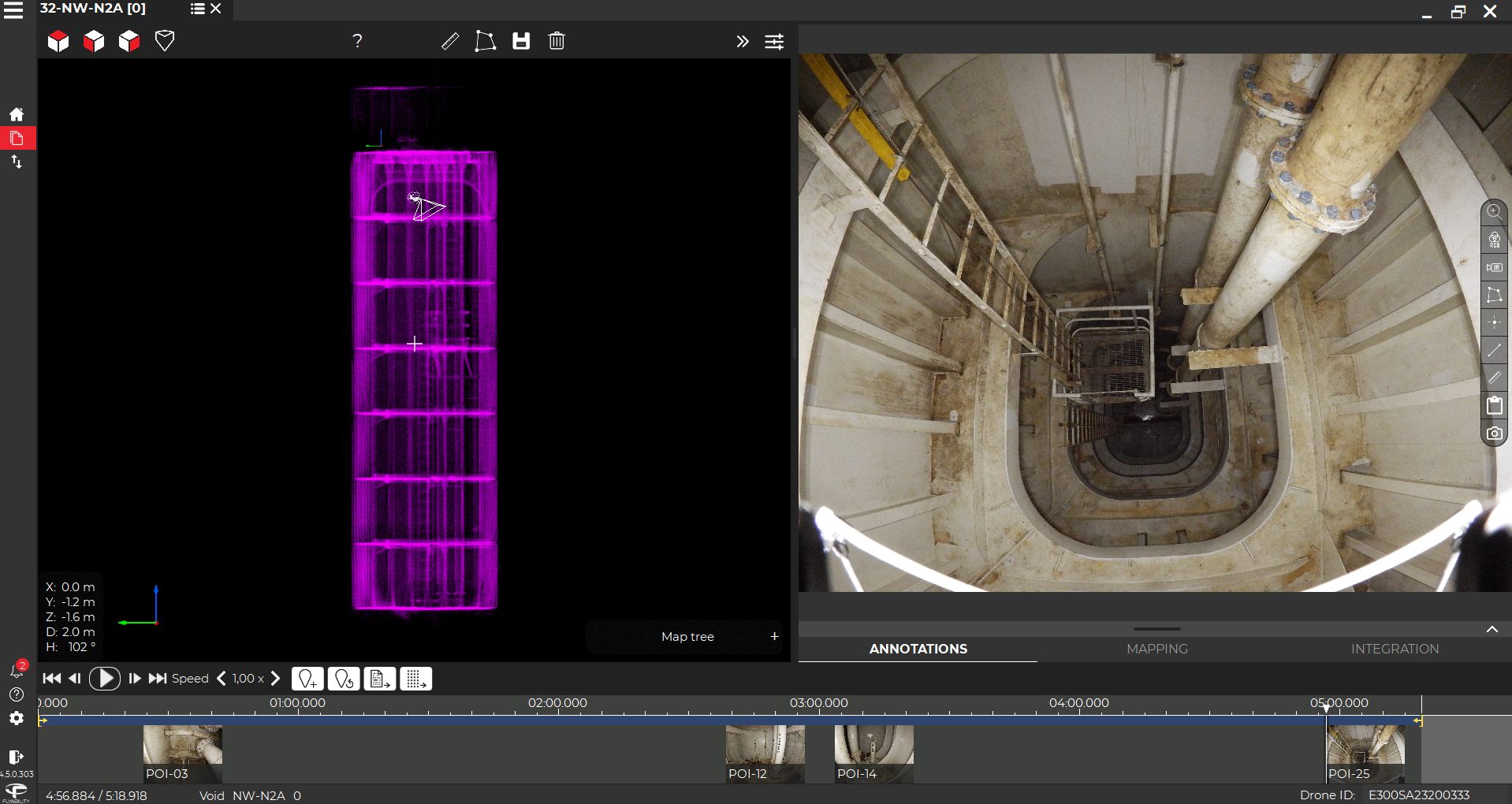

Birdseye’S Drone, equipped with an Ultrasonic Thickness (UT) payload, was deployed to inspect various assets such as flue ducts and silo cones. The results showed a revolutionary improvement in inspection speed, safety, and effectiveness compared to traditional methods.

The Challenge

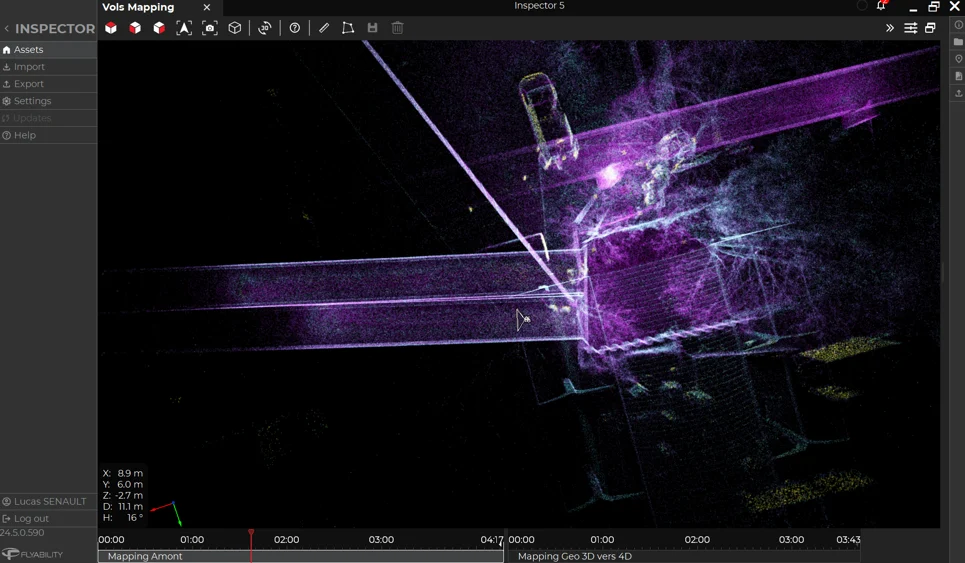

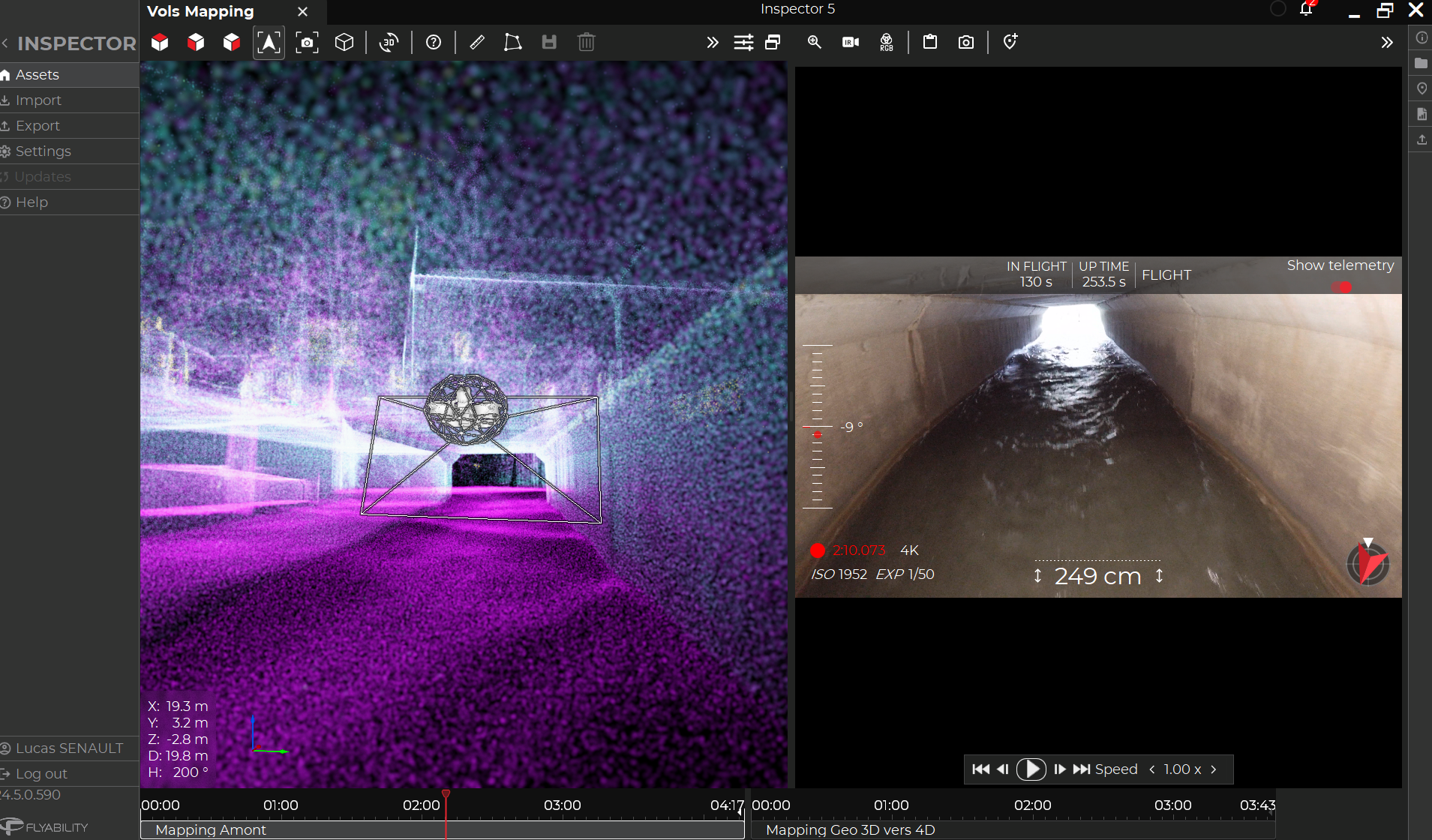

Flue Duct: The flue duct transitions from a rectangular to a rounded shape and channels hot, corrosive gases at 300°C. Its 50-meter height, insulation, and curvature make traditional inspections impractical. With only one open end and limited access, rope-access teams are typically needed, along with permits, safety checks, and over a day of setup. Manual UT inspections often lack precision and consistent documentation.

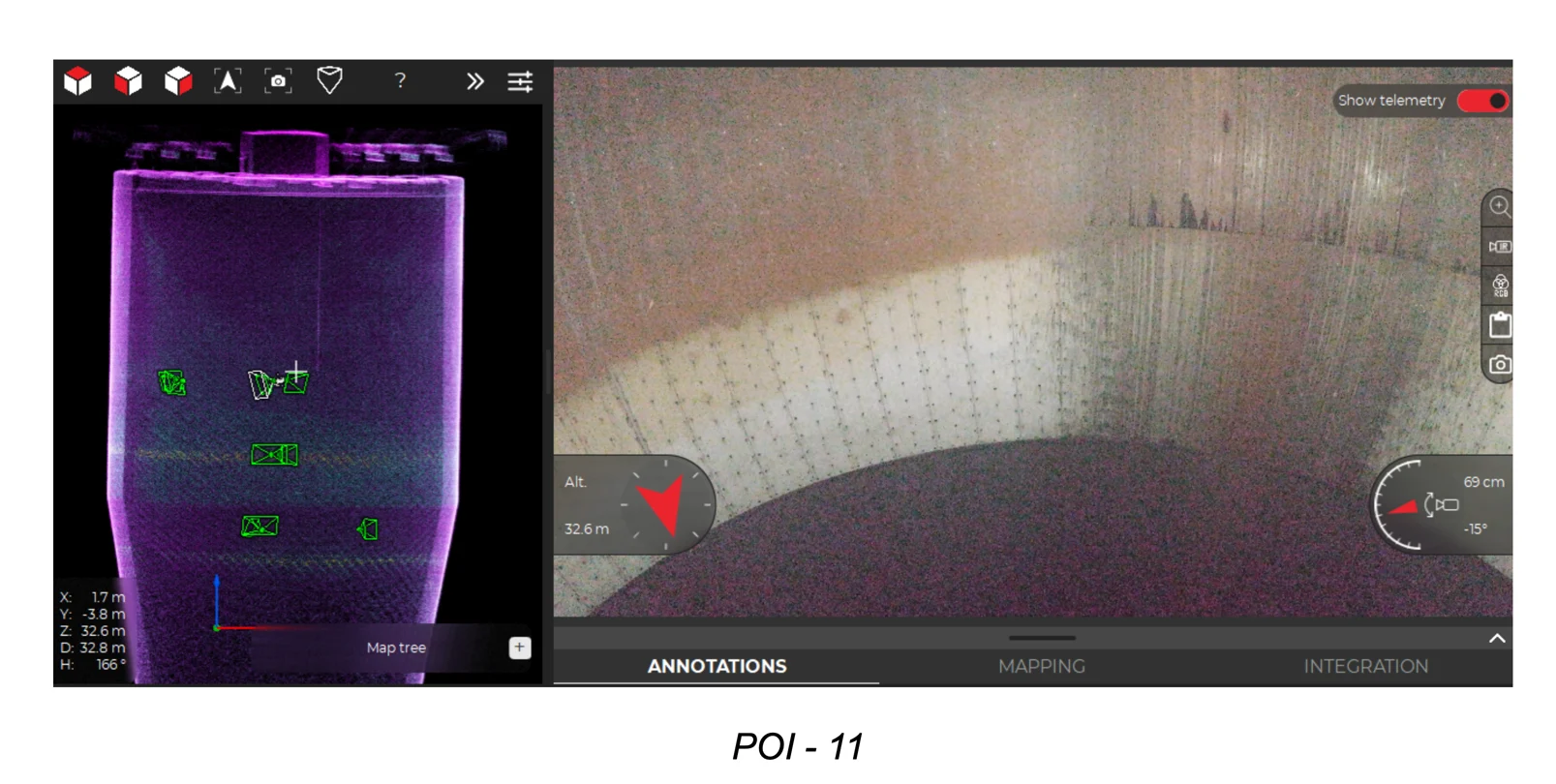

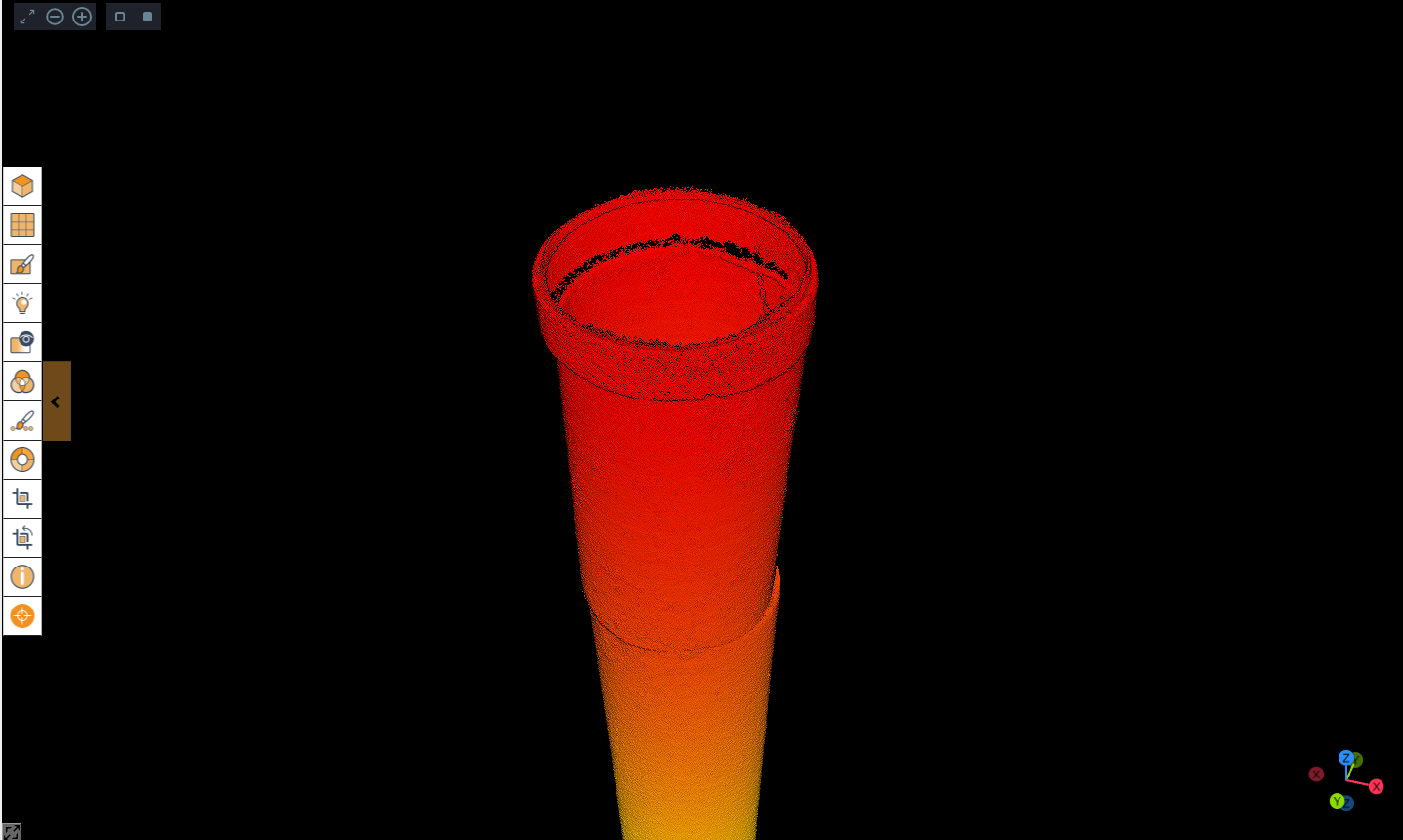

Silo Cones: The silo cones are elevated several meters off the ground, requiring scaffolding or lift equipment for inspection. Manually inspecting all six silos would involve complex planning, high costs, and safety risks. Previous UT data was manually marked with chalk, making it unreliable and difficult to track over time.

What Birdseye Brought to the Process

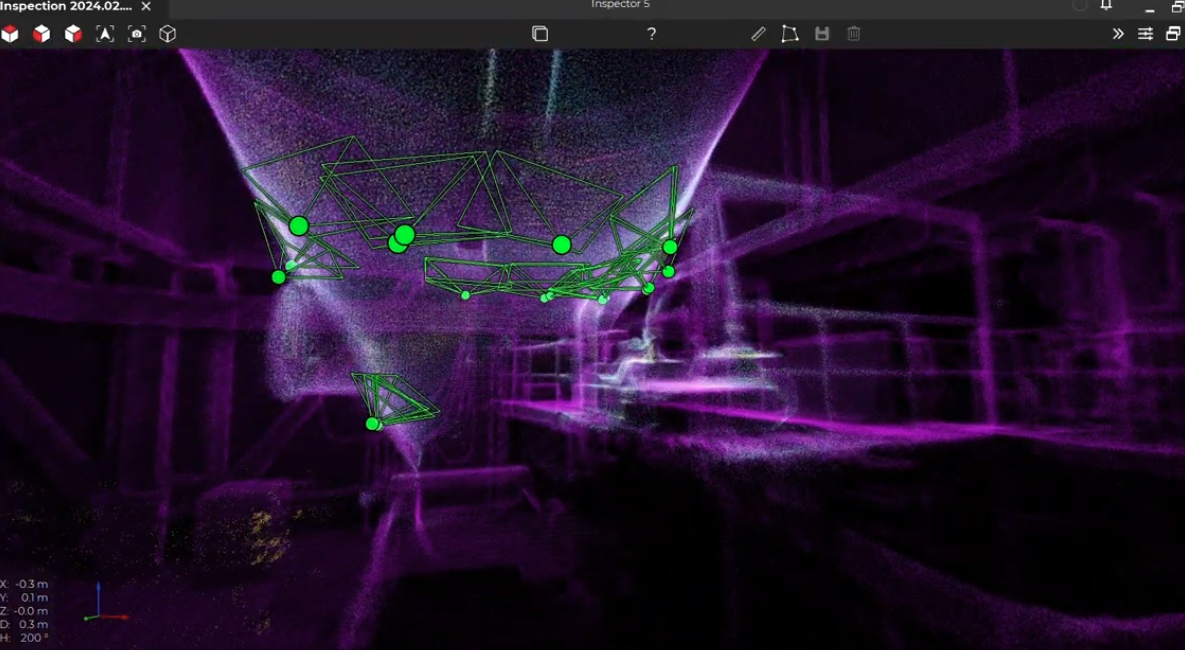

Flue Duct: Using our drone’s UT payload, a single pilot flew through the duct and completed the inspection in just 2 hours—without any manual labor or rope access. Each of the 4 flights captured over 20 ultrasonic measurements, along with high-resolution visuals for identifying key areas of concern.

Silo Cones: A single pilot performed the inspection using 1–2 drone flights per silo. Each flight gathered 25–30 UT measurements, all digitally recorded and geolocated. This streamlined future comparisons and ensured data accuracy.

Conclusion

Using Birdseye’s UT drones marked a major evolution in cement plant inspection. What used to take multiple days, numerous workers, and high-risk setups was accomplished in a single day—safely and thoroughly.

The ability to collect both UT and visual data quickly minimized downtime and costs, and empowered the plant to adopt proactive maintenance strategies. Birdseye’S Drone set a new benchmark in industrial inspection—smarter, safer, and more sustainable.