Overview

Proper management of stockpiles is essential for operational efficiency in industrial plants. Incorrect material estimates can lead to shortages, production delays, and increased downtime costs.

- Requires workers to operate at heights using GNSS/GPS equipment, increasing risk levels.

- Different sites require different inspection frequencies—one-time or scheduled—so a one-size-fits-all method doesn’t apply.

- Surveys must be efficient and non-disruptive to operations.

- Accurate material measurements are crucial for delivery planning and inventory control.

- Personnel may need to climb unstable piles, posing safety risks.

- Human error, technique variation, and limited access can lead to inaccurate measurements.

The Solution

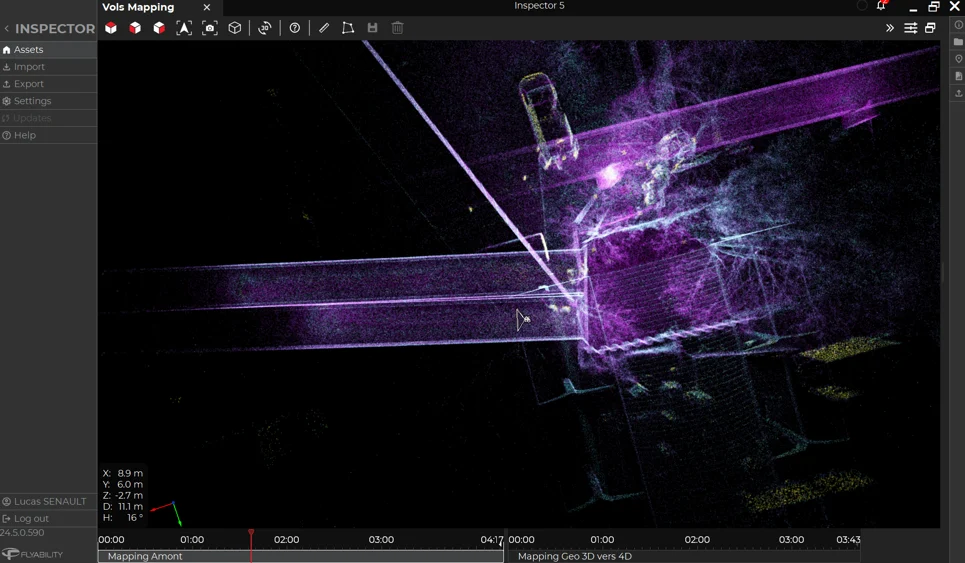

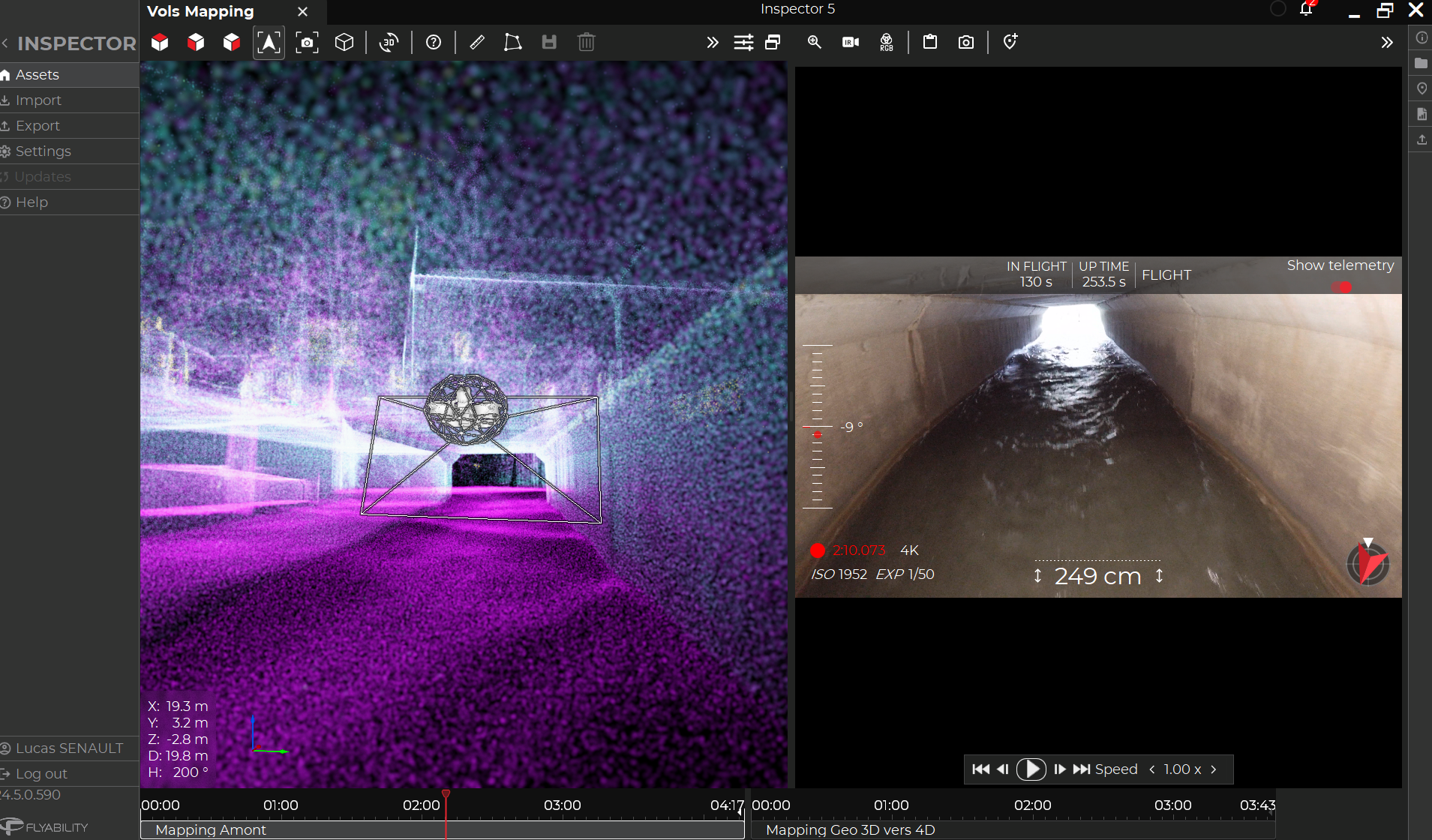

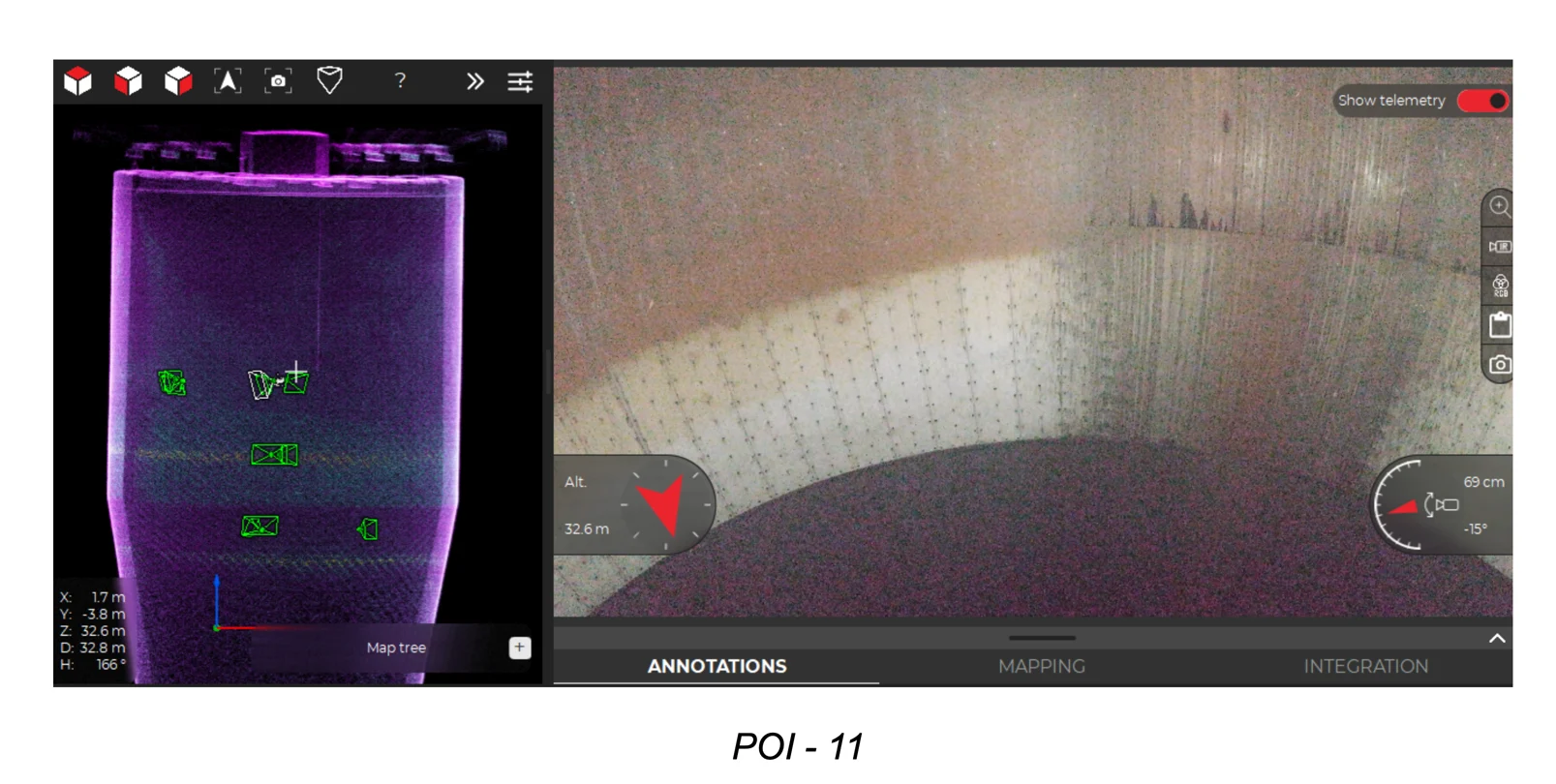

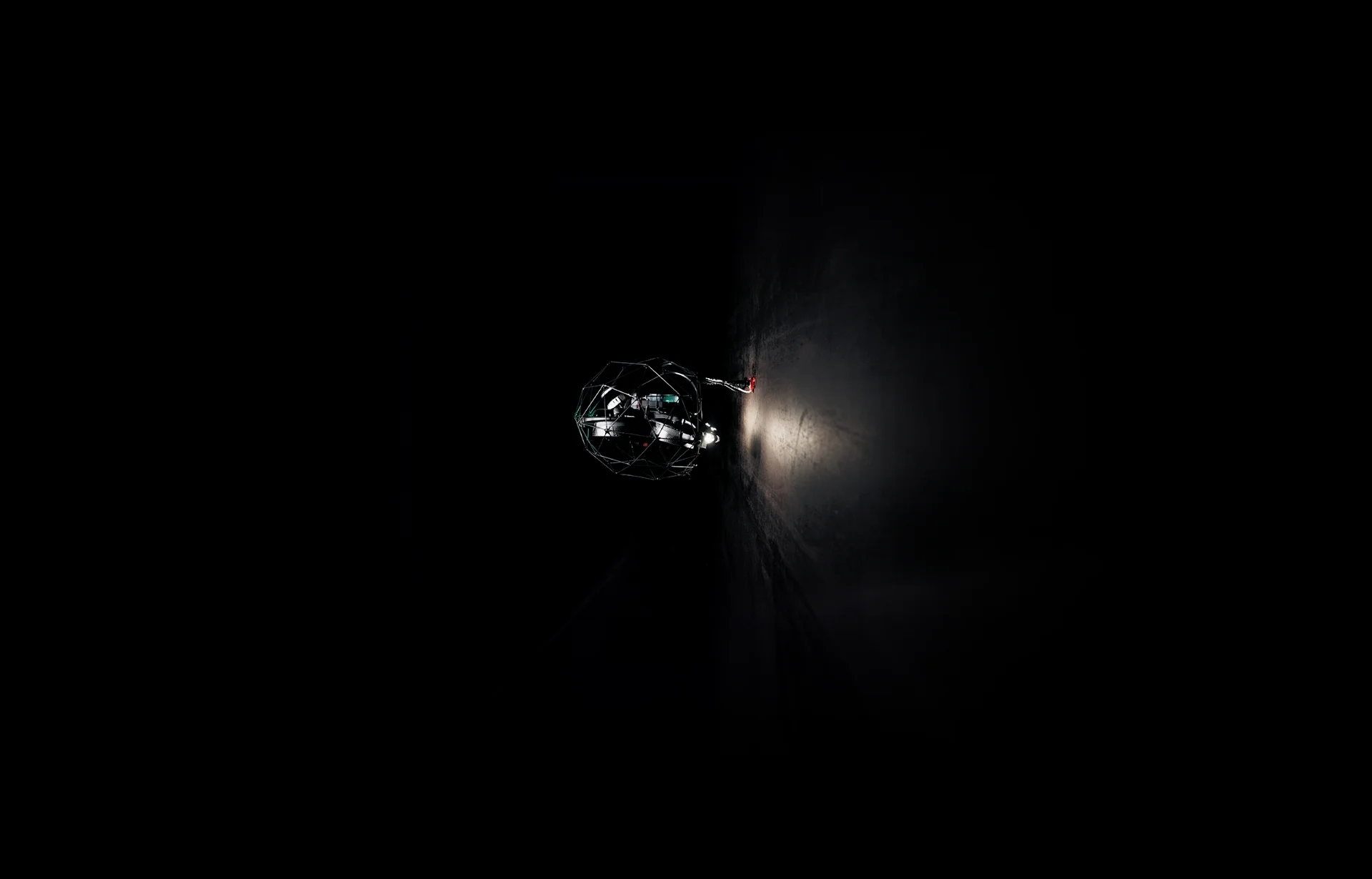

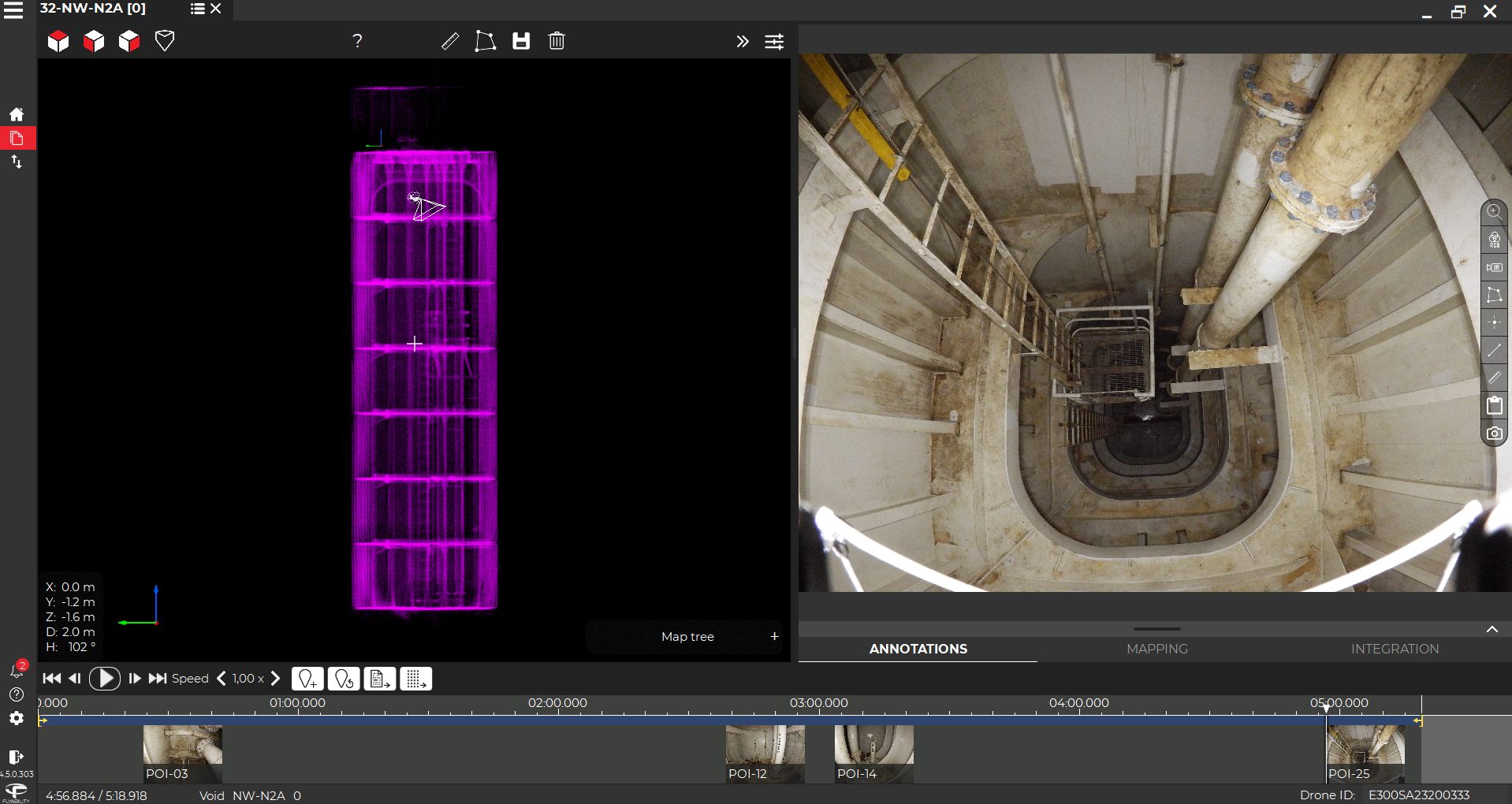

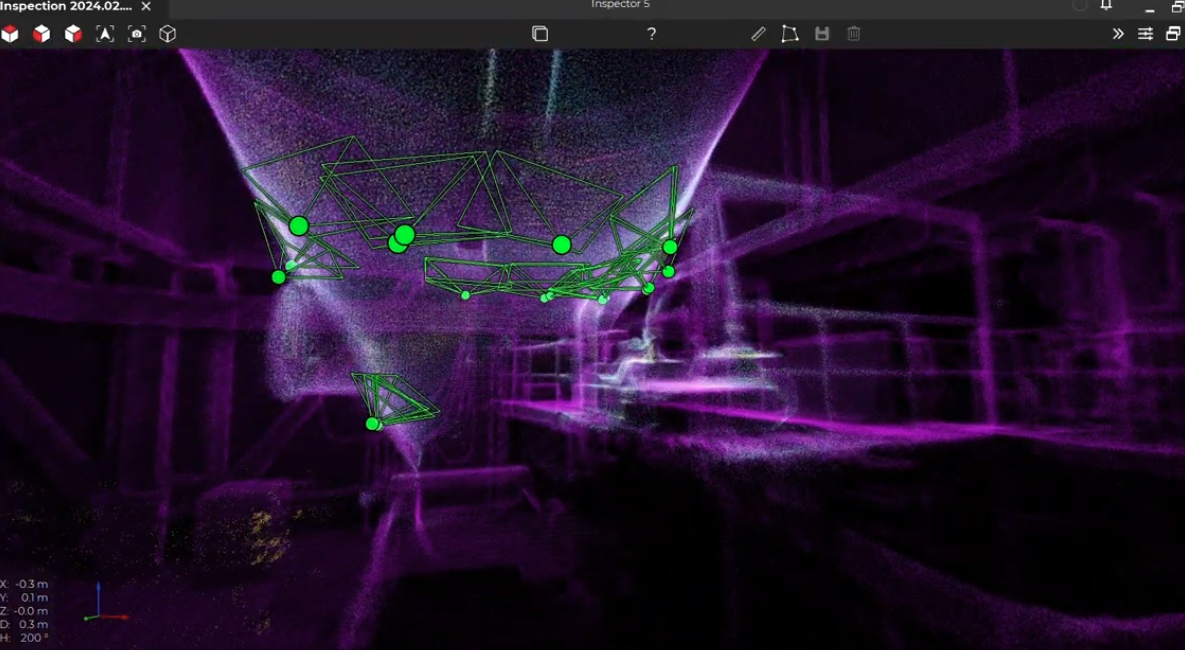

Birdseye’s drone, designed for collision tolerance, eliminated the need for personnel to climb hazardous piles. It flew in confined spaces, gathered accurate data, and processed it efficiently—enhancing both safety and productivity.

- Enhanced Safety: No need for workers to physically walk over stockpiles.

- Data Collection: The drone collected reliable data quickly and safely.

Outcome

| Parameter | Without Birdseye | With Birdseye |

|---|---|---|

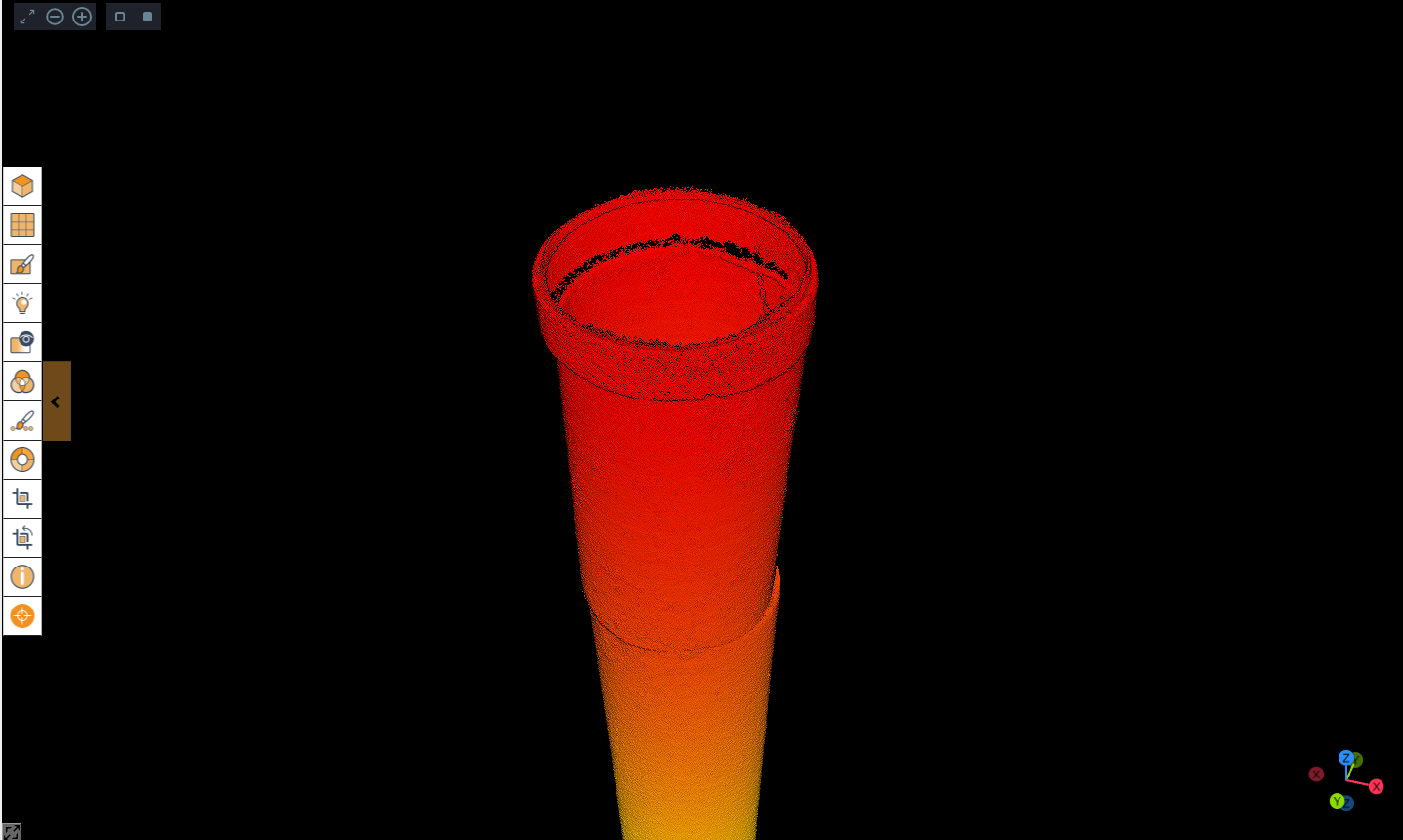

| Inventory Control | Manual estimates often inaccurate and time-consuming. | Drone provided precise data for effective stock management. |

| Speed | Surveys took several days with manual methods. | 30 stockpiles surveyed in 7–8 quick drone flights. |

| 3D Modeling | Limited or no spatial modeling capabilities. | Highly accurate 3D models of stockpiles and bunkers produced. |

Conclusion

With LiDAR technology and a robust drone design, Birdseye revolutionized stockpile surveying. It delivered more reliable data compared to manual methods and eliminated safety hazards for personnel.

The operation showcased how drone-based inspections offer a smarter, faster, and safer alternative to traditional approaches in industrial settings.