Overview

Significant periodical inspections are conducted for all shipping vessels every 5 years where smaller inspections also play a crucial role. Depending on the age of the ship, the frequency and intensity of the inspections differ. Inspection is vital for the ship to get certified for safe operations. Moreover, the process is expensive with ships waiting in dry dock for work to be completed.

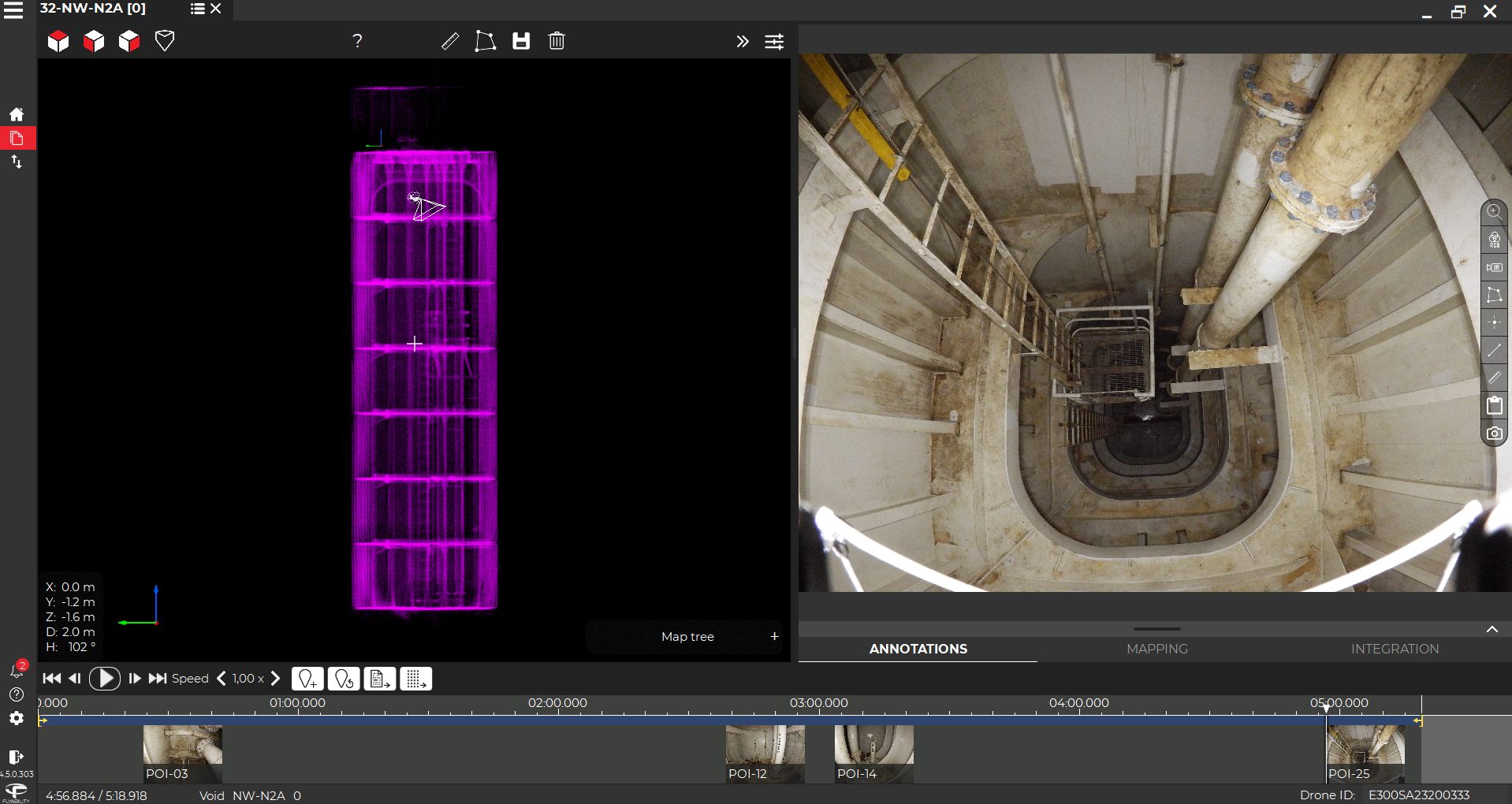

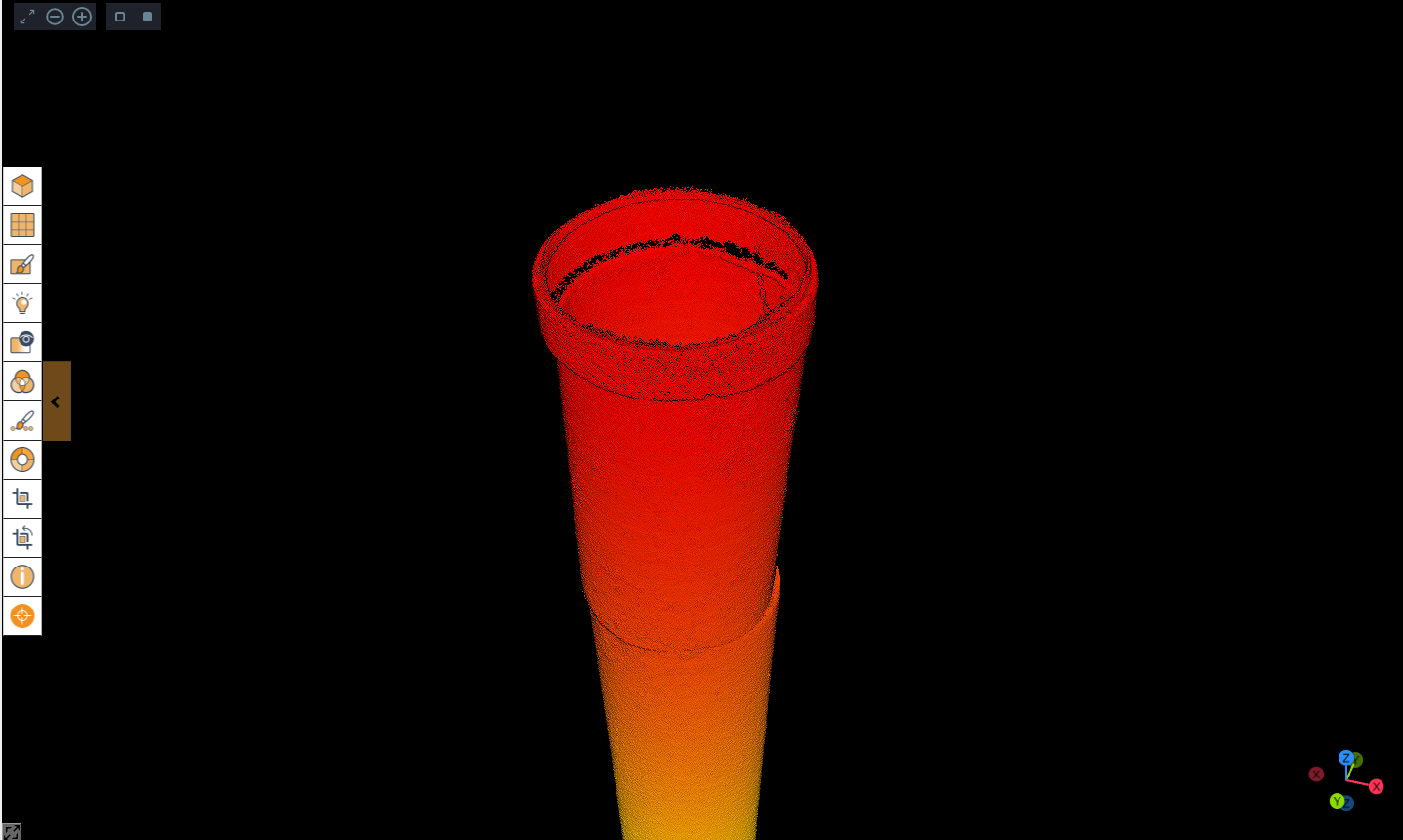

Inspection of the ship’s hull for ultrasonic thickness measurements and visual inspections of target areas is carried out. When the ship is at sea, reviewing the midship area is prioritized for spotting faults that cannot be found by laborers or are hidden within the ship’s structure.

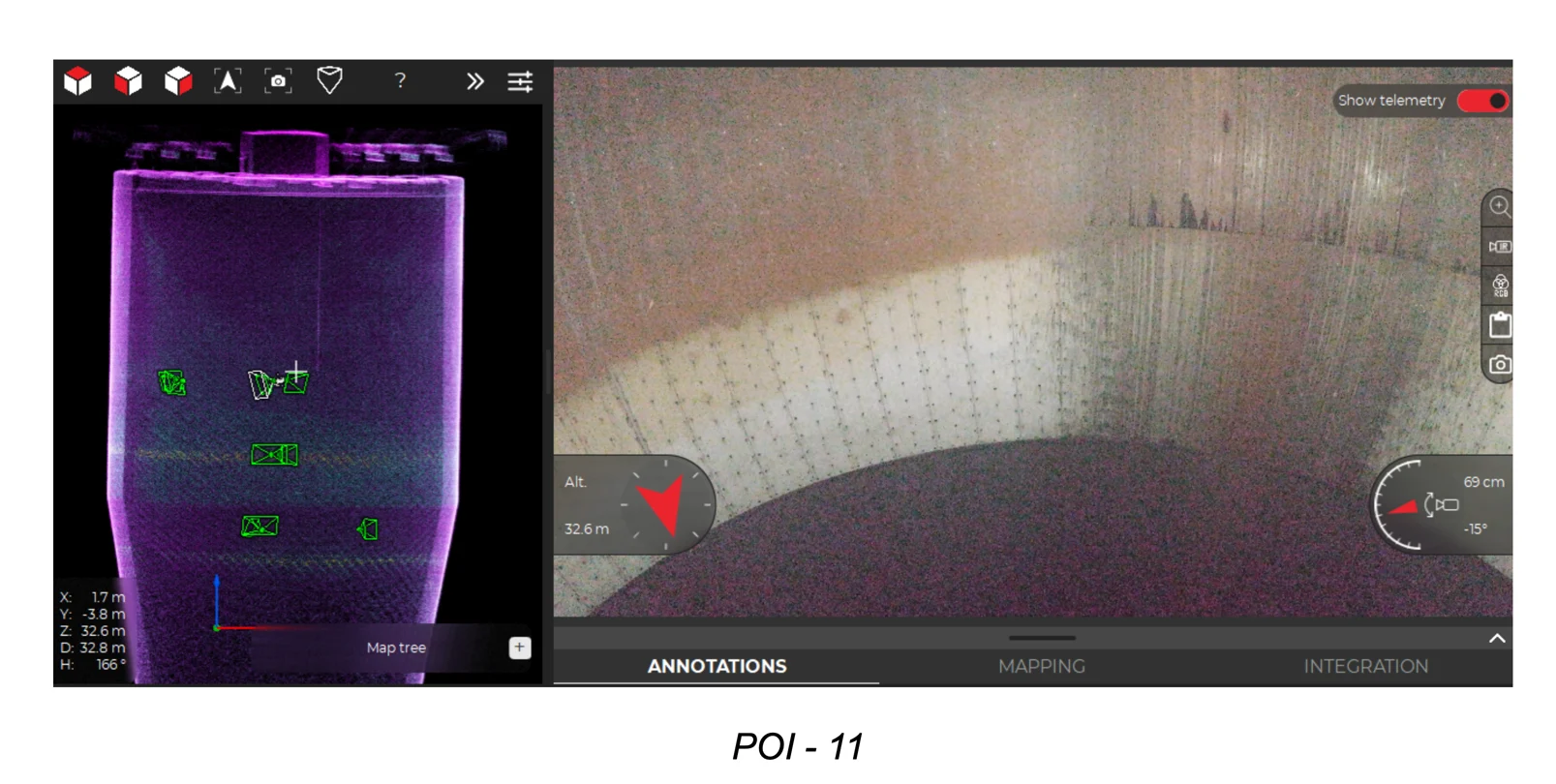

12 oil tanks in medium-sized ships had to be inspected. Thickness measurements and detailed visual inspections of the ship’s oil tanks were required as part of its scheduled survey. The ship’s oil tanks were 38 by 28 by 20 meters in size, each reinforced with 6 transverse web frames in each of the cargo oil tanks and separated by solid walls between the tanks.

Challenges

- Time consuming: Requires many hours of work to carry out the inspection process.

- No visual data: Manually visual data cannot be gathered as data must be captured at arm’s length from the object being inspected.

- Manual labour: 30 people and scaffolding are required. Leftover scaffolding parts can be accidentally drawn into the tank’s pump, potentially causing damage that may require costly drydock repairs.

- Permit issued: Special permits are required for working in confined spaces or at heights on ships.

- High cost: Inspections in drydock can cost between $4–6 million. Surveying a 15-year-old tanker may cost $300,000–$700,000.

Solution

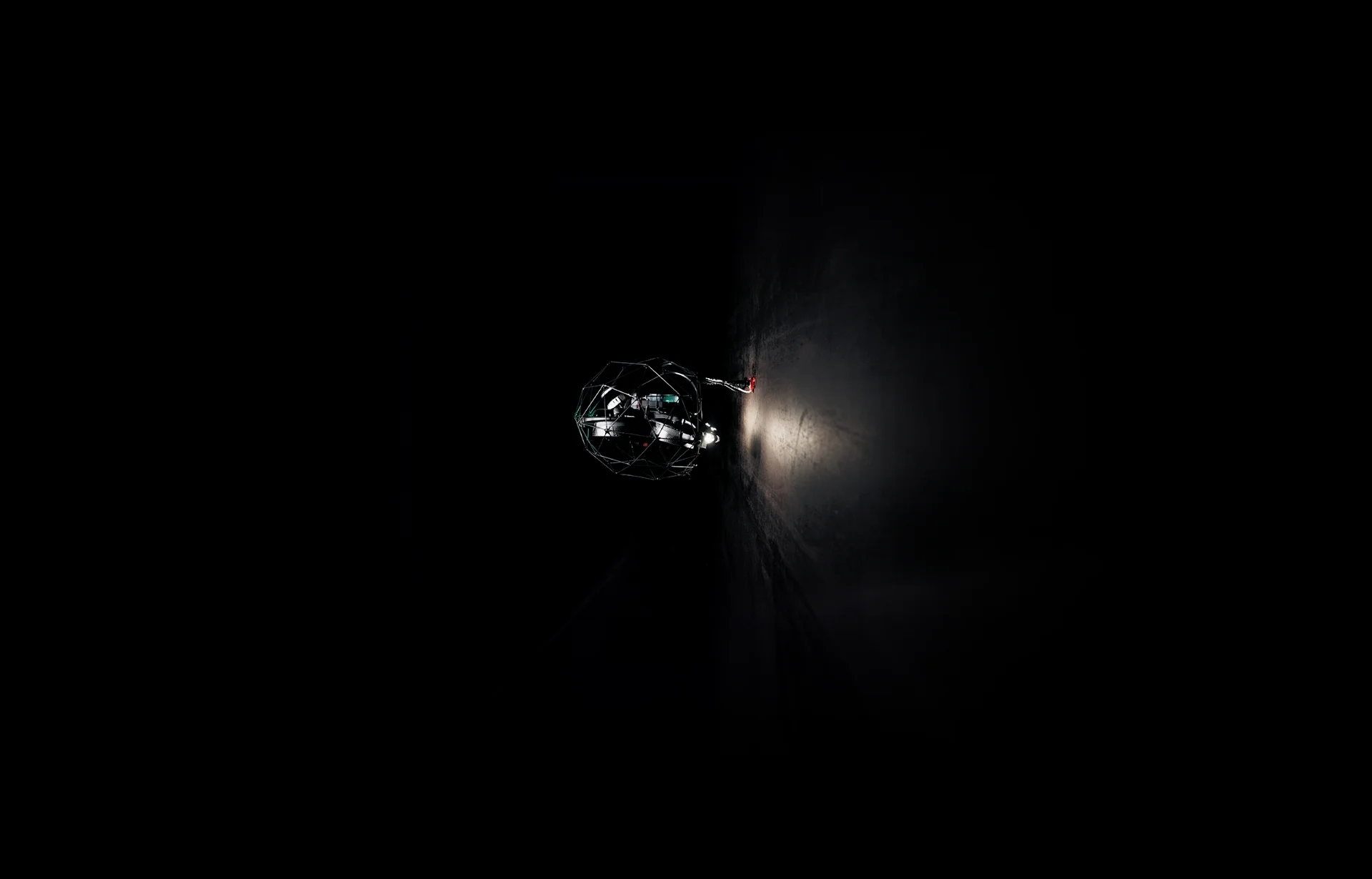

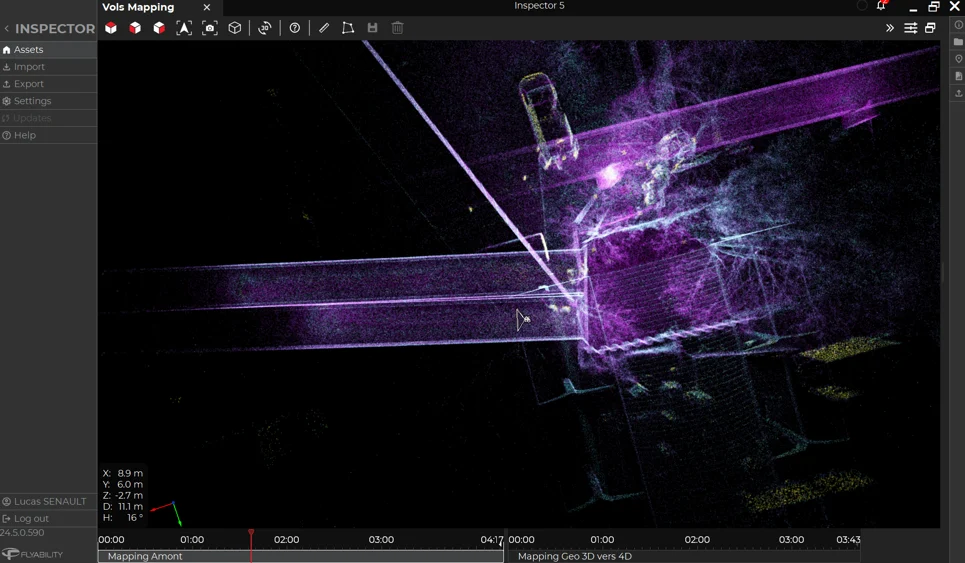

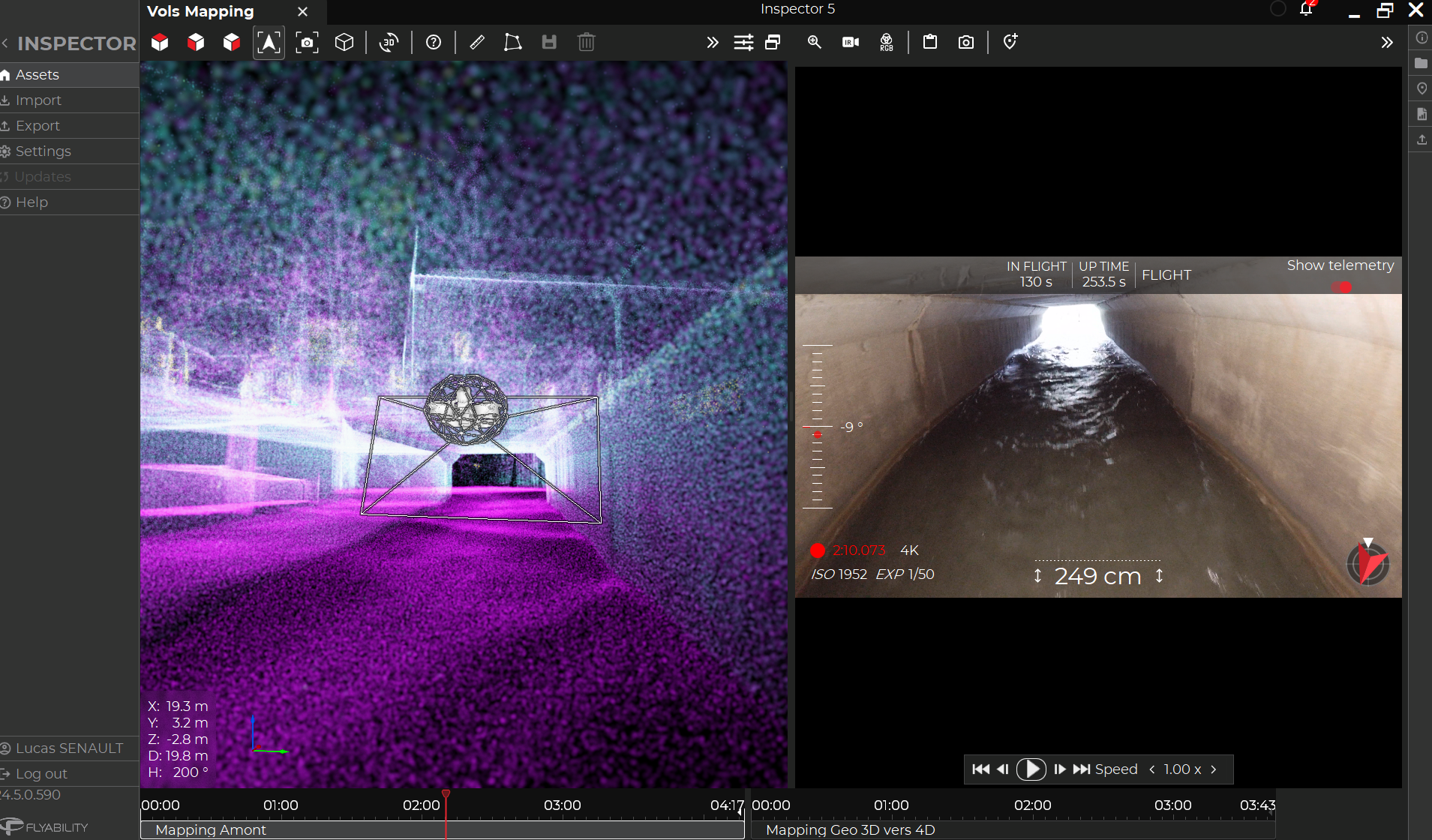

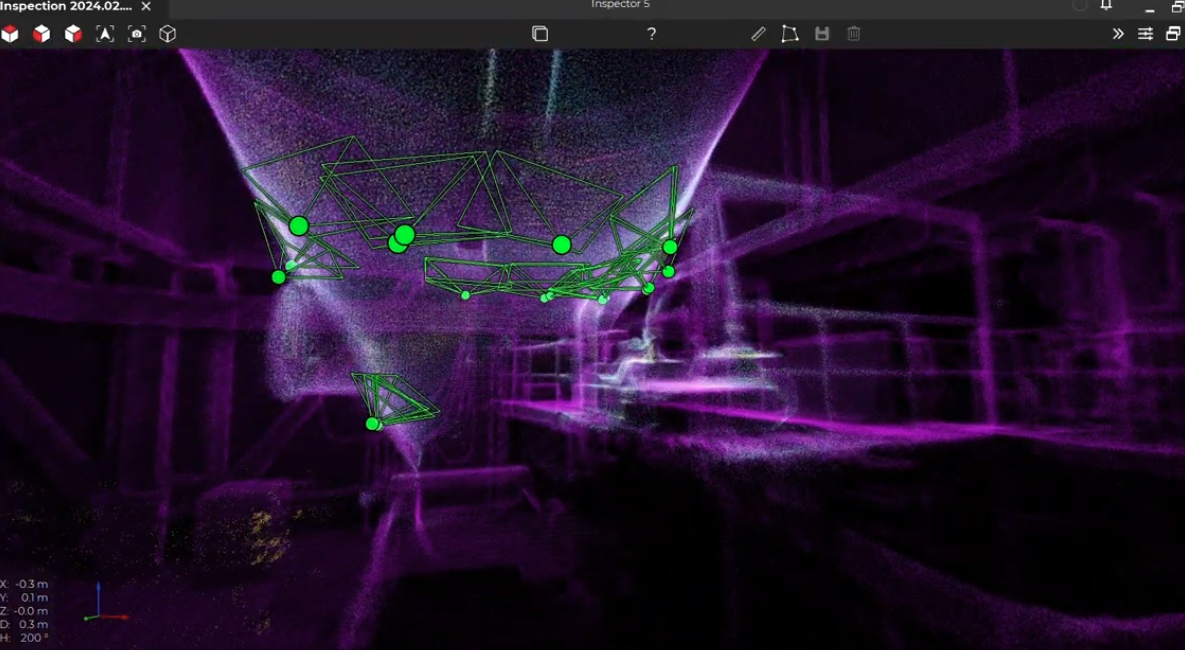

Due to the drone’s advanced technology, it streamlines the process—removing the need for scaffolding, cutting out hazardous risks, and saving tremendous costs. Our drone inspections are faster than traditional methods while gathering the UT and visual data required for a ship survey.

Comparison between Traditional and Birdseye:

| Traditional | Birdseye |

|---|---|

| Labour intensive and slow | Uses UT probe with 2 drones |

| Requires scaffolding (time consuming) | Inspection starts as soon as equipment is set up |

| Slower visual and thickness inspections | Quicker inspections guided by a class inspector |

| Limited flexibility in accessing areas | Drone flies around tanks, taking measurements in required and additional places |

| Longer inspection duration | Both UT and visual inspections completed within 7 days |

| Manual verification of measurements | Pilots cross-check measurements to ensure compliance with inspection plan |

Conclusion

Birdseye paved the way for higher standards for drone inspection across industries like maritime, oil and gas, and asset management.

We delivered comprehensive reports in the required format, demonstrating the drone’s value not just for UT inspections, but for a wide range of ship inspections.