Overview

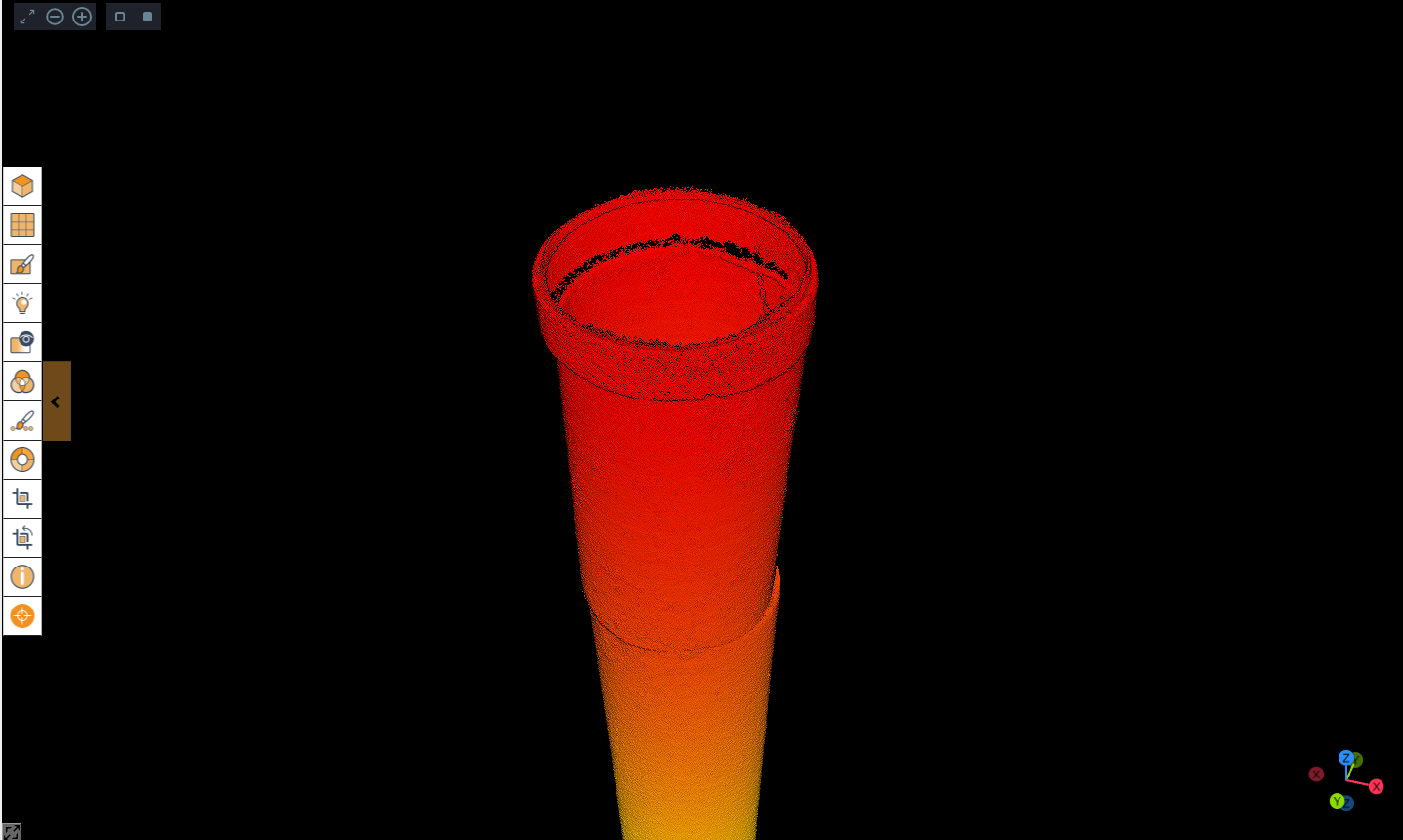

In 2022, 4.1 billion tons of cement were produced, making it one of the most in-demand construction materials. A key part of cement production involves heating limestone in kilns at 1300–1450°C to create calcium oxide. The resulting hot gases are expelled through large chimney stacks — 120 meters tall and 4 meters wide — built with inner and outer concrete sleeves to withstand extreme heat and pressure.

Challenge

In February 2023, an engineer spotted a tilt in the chimney stack, prompting an urgent inspection. To carry this out, the plant had to temporarily shut down, as both kilns relied on the same chimney.

Solution

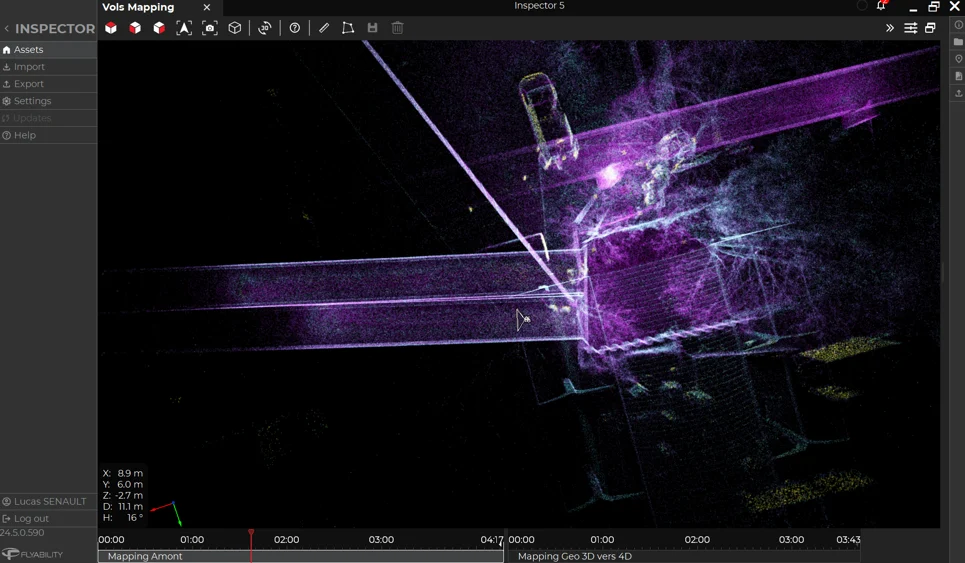

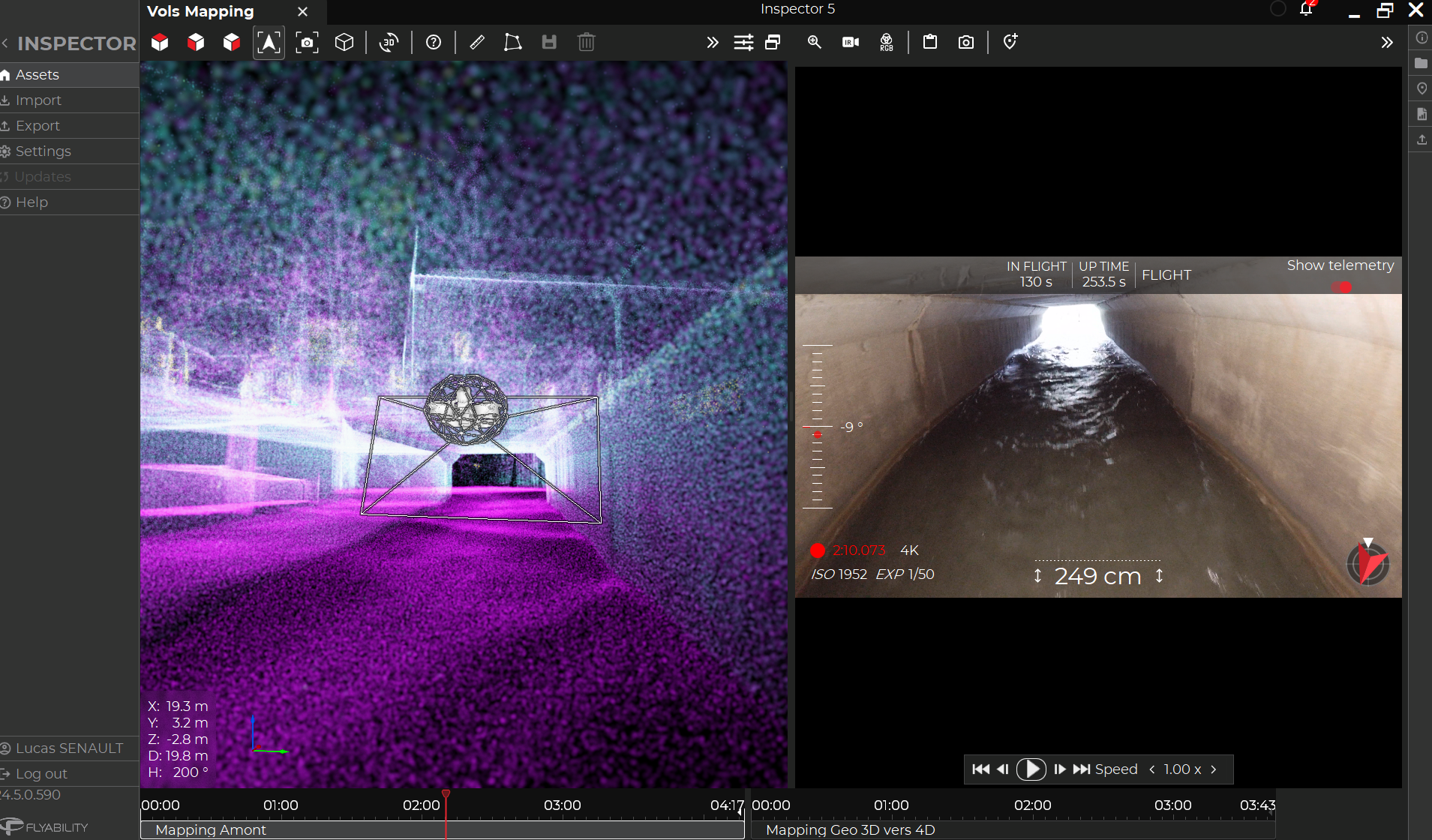

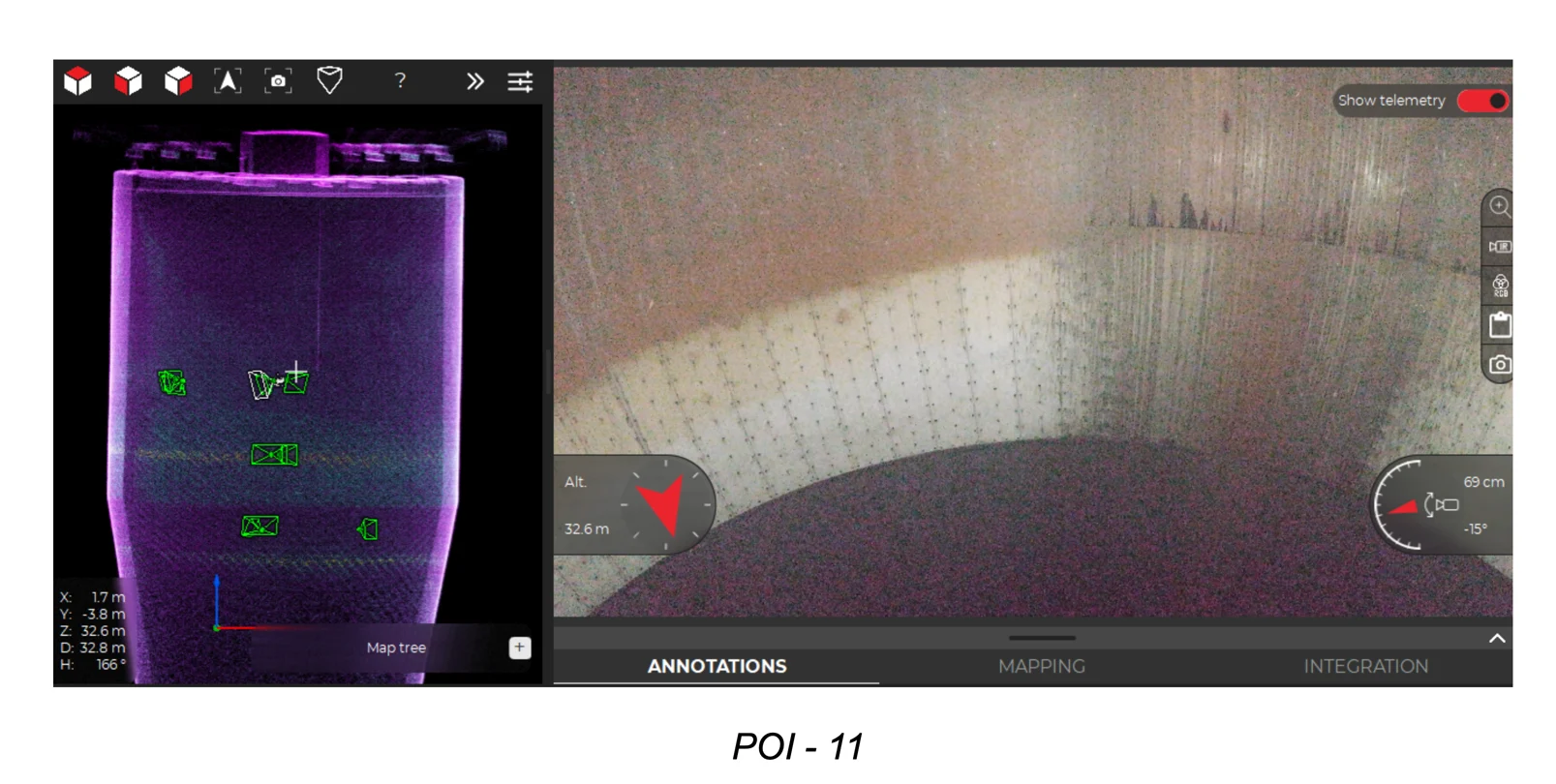

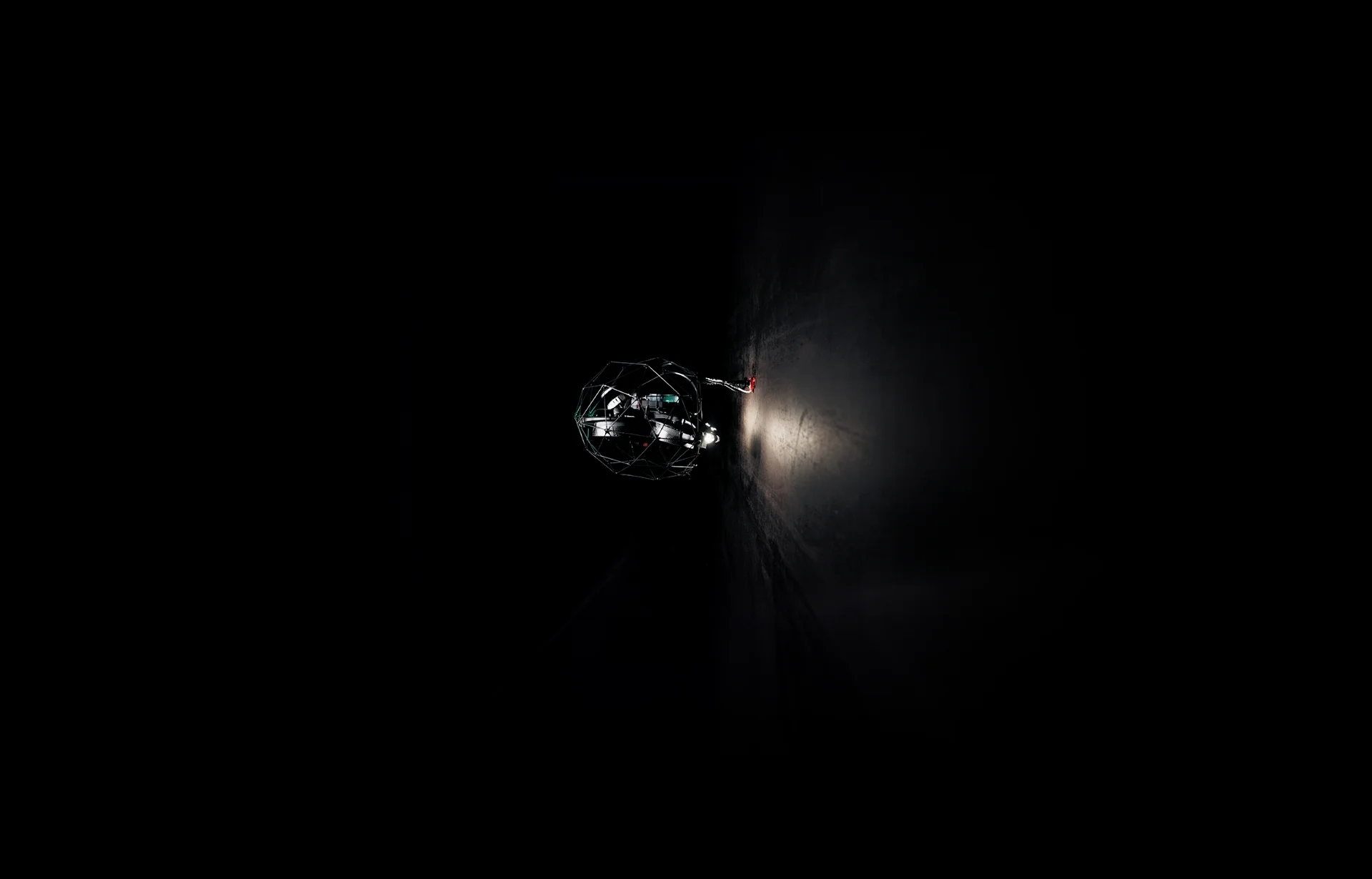

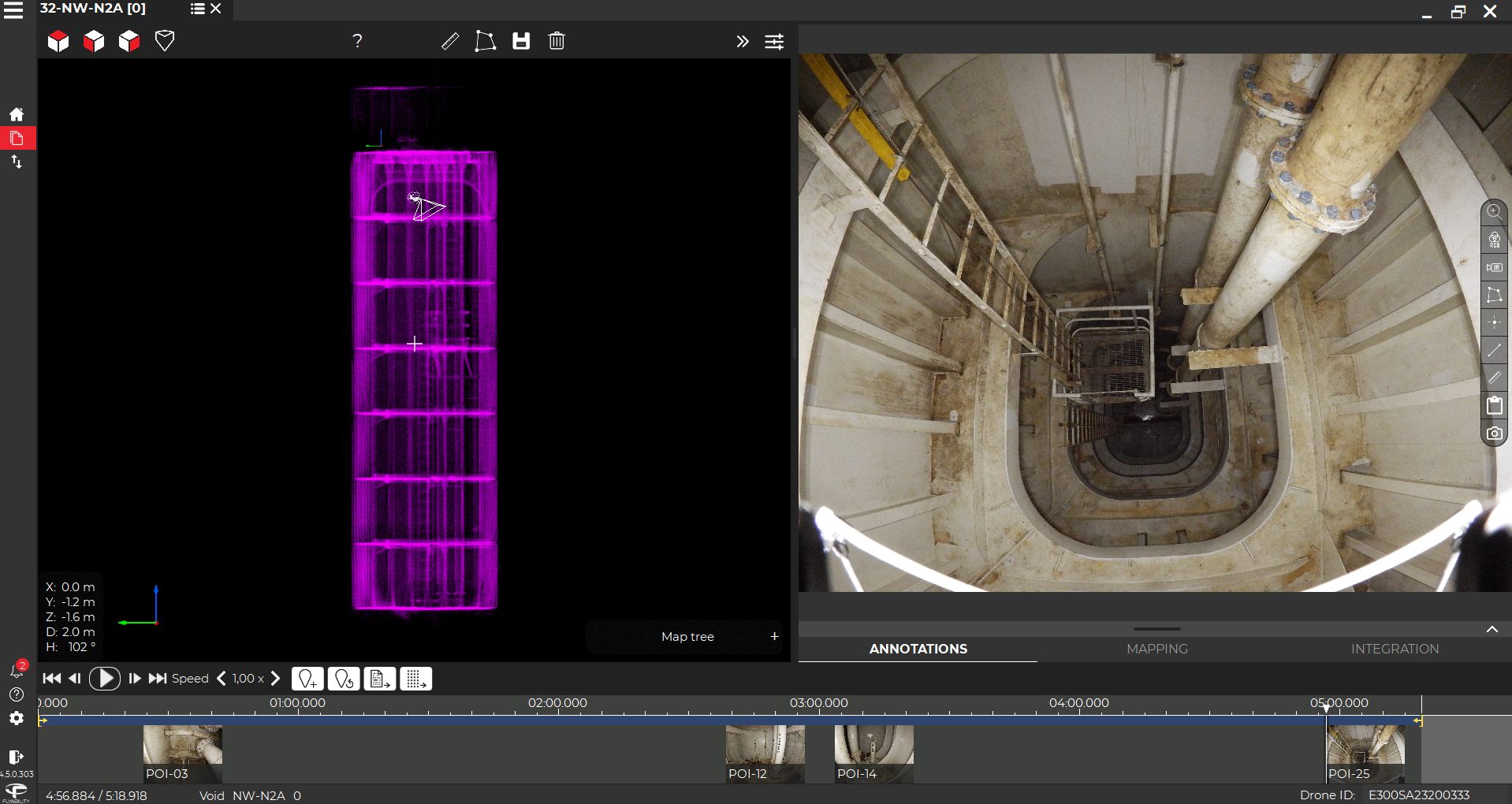

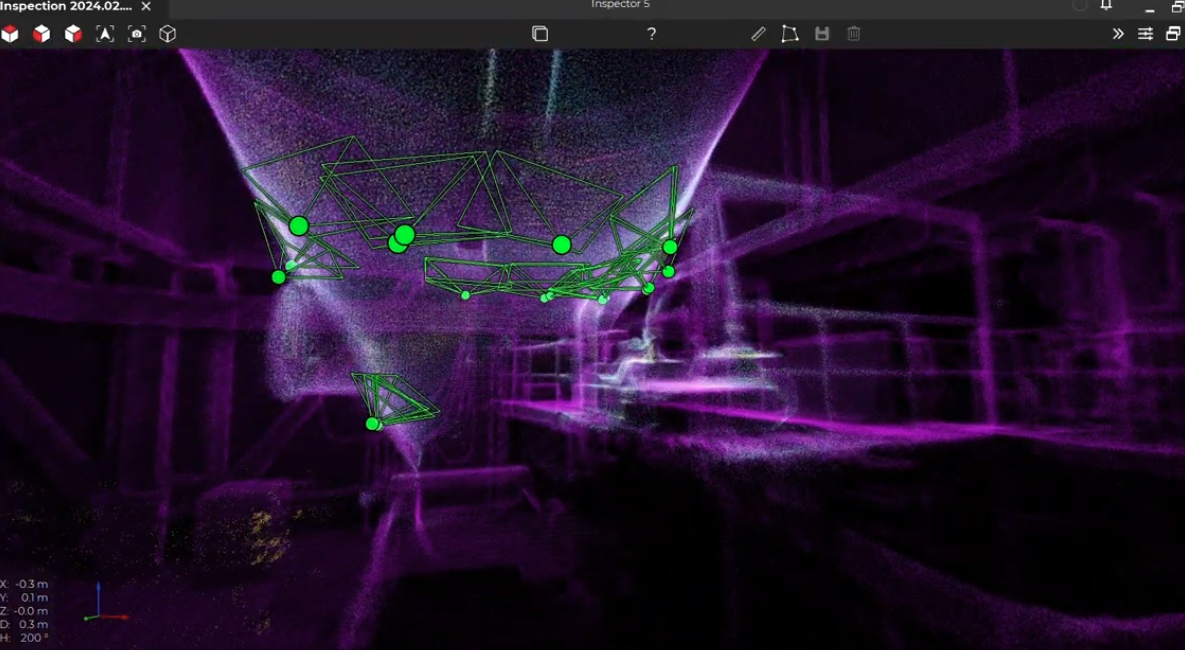

A trained pilot used the Elios 3 drone to fly inside the chimney, collecting visual and LiDAR data and generating a 3D model of the structure. This modern method replaced the need for cranes — which take 1–2 days to set up and cost up to €30,000 — with a faster, more cost-effective process.

Elios 3 completed the inspection in just one hour. The chimney cooled for 1–2 hours, and the entire operation was done in approximately three hours — drastically reducing downtime and cost.

Inspection Results

The data revealed that the inner concrete sleeve had shifted 150mm eastward in the top 7–10 meters, causing a 4-degree lean and posing a major structural risk. Engineers used the 3D model to assess the damage and plan repairs accurately. They removed the damaged 7-ton section, cleaned and inspected the outer tube, and installed a new concrete piece — all completed in just two weeks.

Conclusion

The ease of drone deployment saved at least two full days compared to traditional workflows, proving how drone-based inspection can be faster, safer, and significantly more efficient in critical infrastructure inspections.