Overview

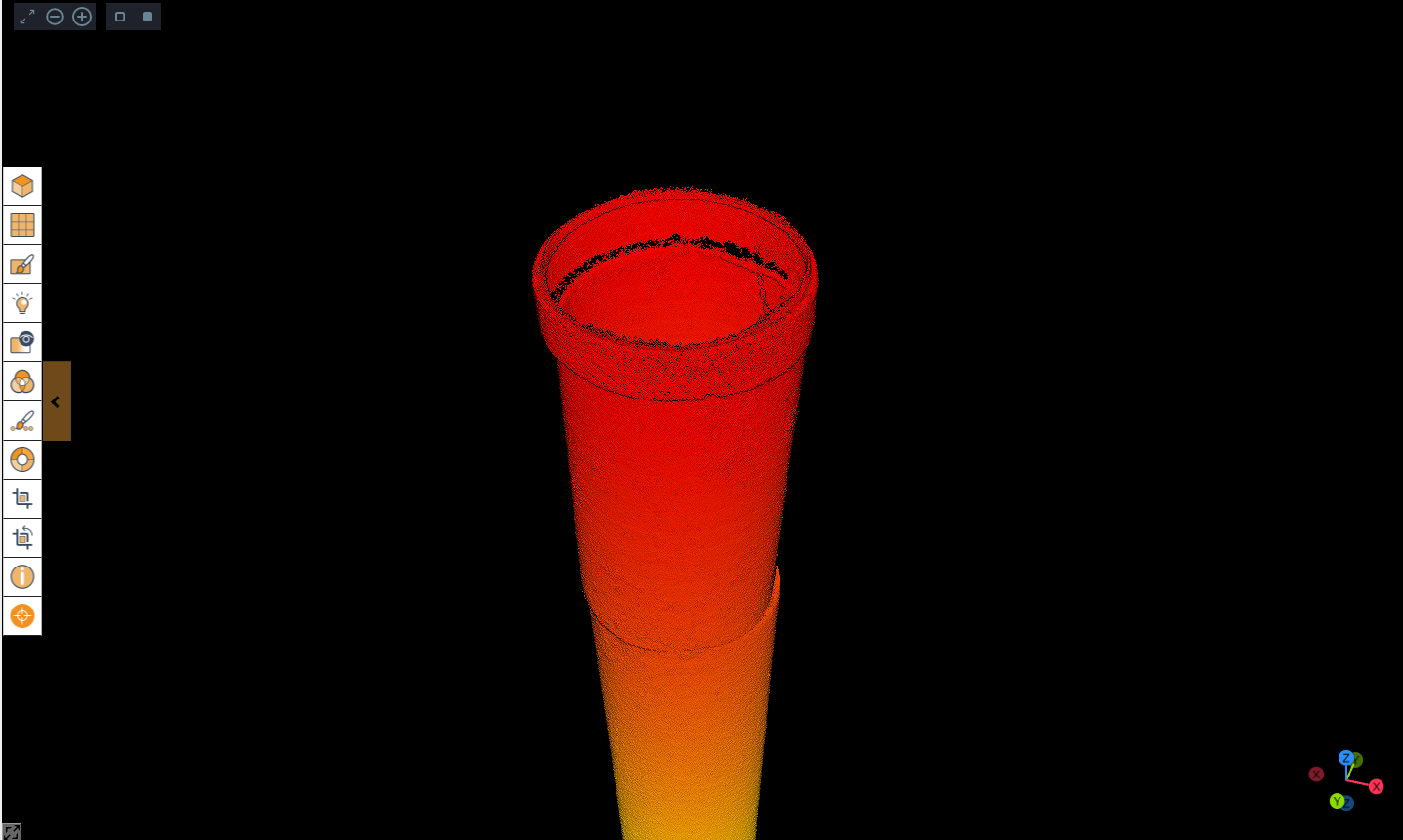

Three key challenges that impact storage tanks are oxidation, surface wear, and structural deterioration

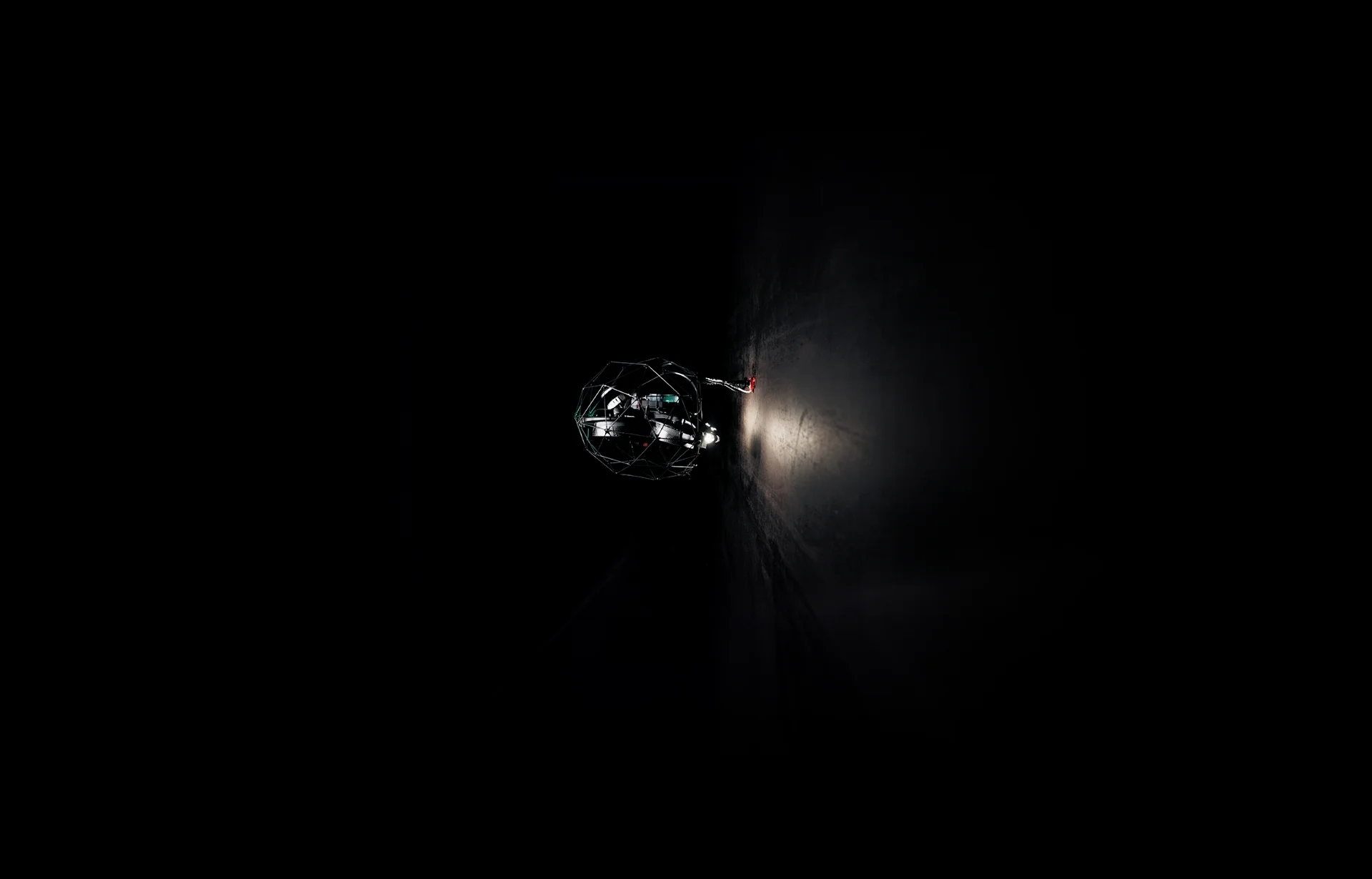

Which leads to minimization of strength and reliability of storage tanks. Continuous monitoring and inspection processes are highly necessary to identify and eradicate such issues early. When defects go unnoticed, the consequences can include leaks or explosions that harm the environment, affect people’s health, and put workers’ lives at risk. This is where Birdseye’s drone-based inspection services come in leveraging Voliro T.

Equipment involved to conduct inspection:

Voliro T Drone for Ultrasonic Testing

The Voliro T drone is equipped with advanced UT (Ultrasonic Testing) tools that can take up to 200 readings per hour, inspecting tank walls, roofs, and floors without needing direct access.

Two types of UT tools on the drone:

Standard UT Probe

|

EMAT Probe

|

Solution

|

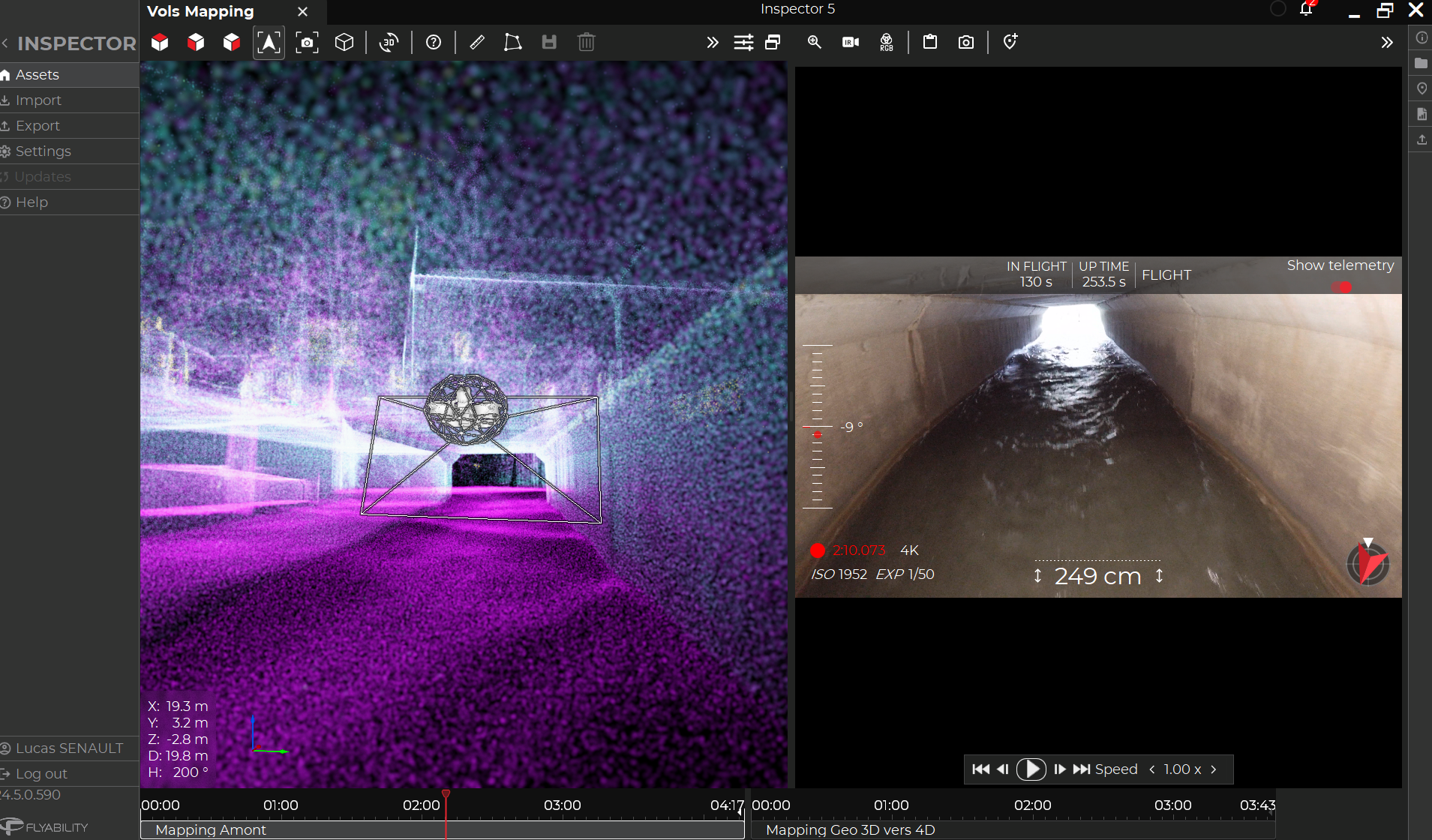

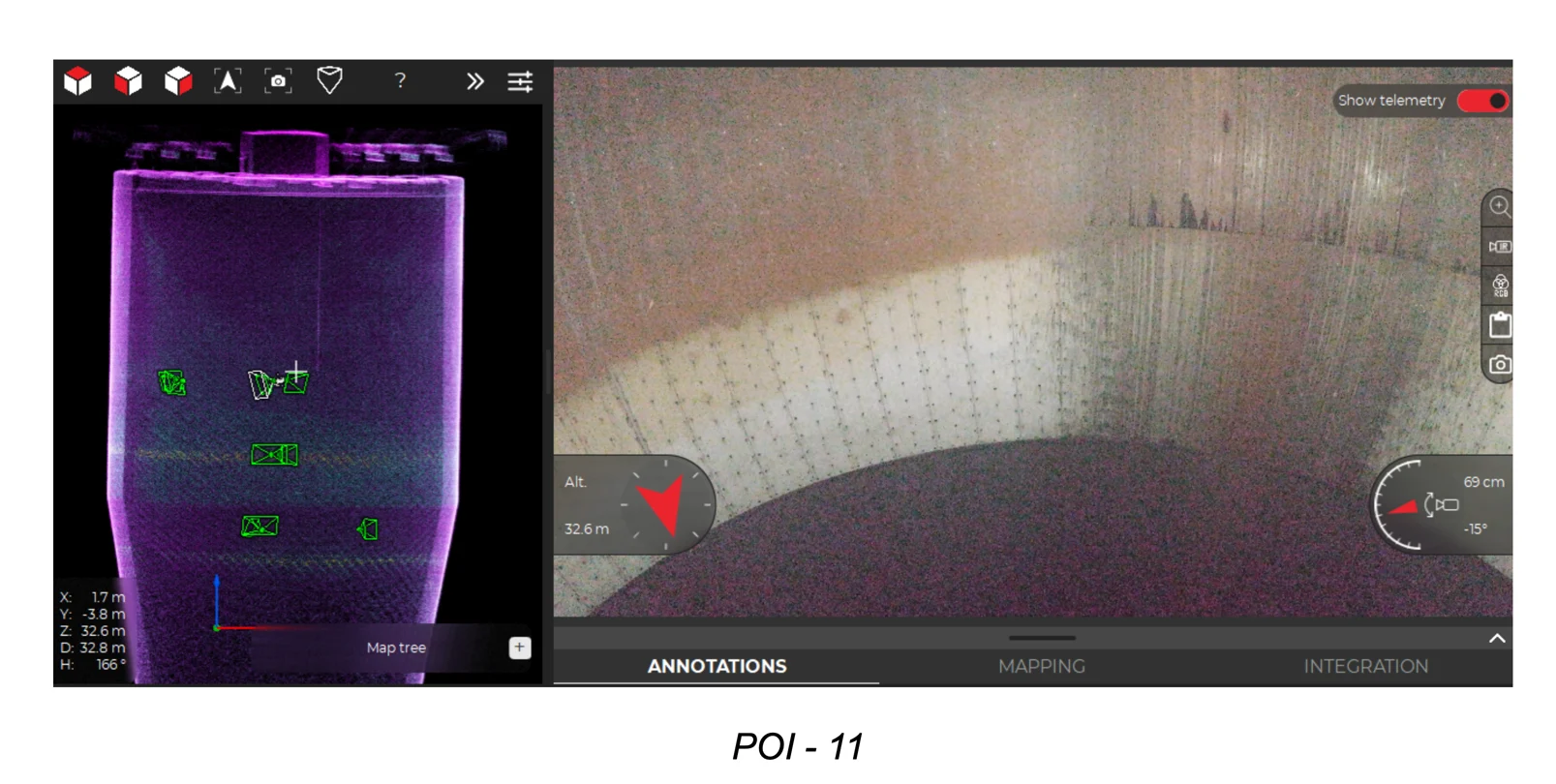

1. High-Definition Visual Cameras Equipped with dual cameras where a 4k inspection camera offers a comprehensive view of the surface and it detects cracks with ease. 2K Pilot Camera provides a wide-angle forward-facing view for navigation and situational awareness. |

2. Sensor Integration Along with Ultrasonic Testing (UT) Probes and Electromagnetic Acoustic Transducer (EMAT) Probes, Dry Film Thickness (DFT) Gauges are utilized to analyze coating thicknesses precisely.

|

|

3. Real-Time Data Streaming 5G connectivity enables effortless data transfer to and fro from the Voliro cloud. |

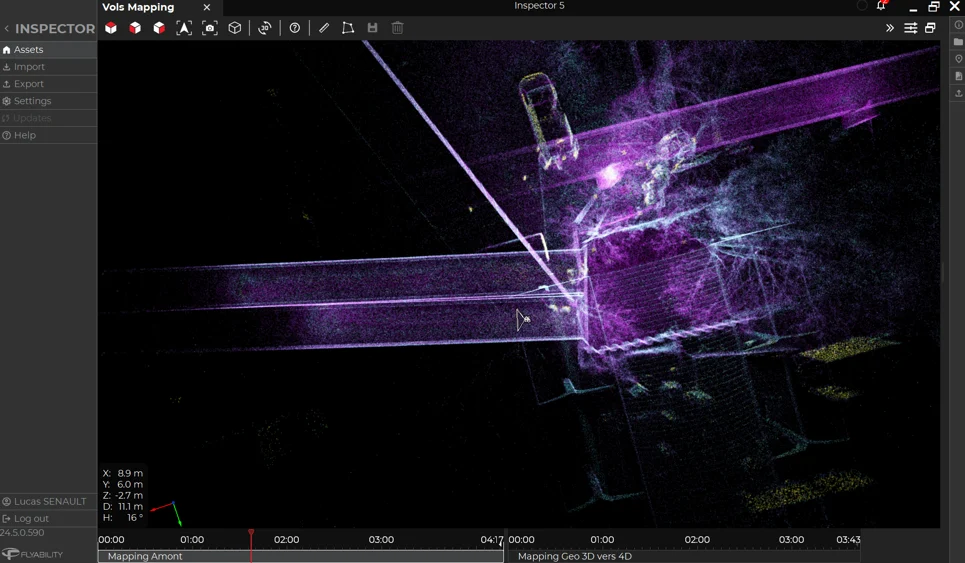

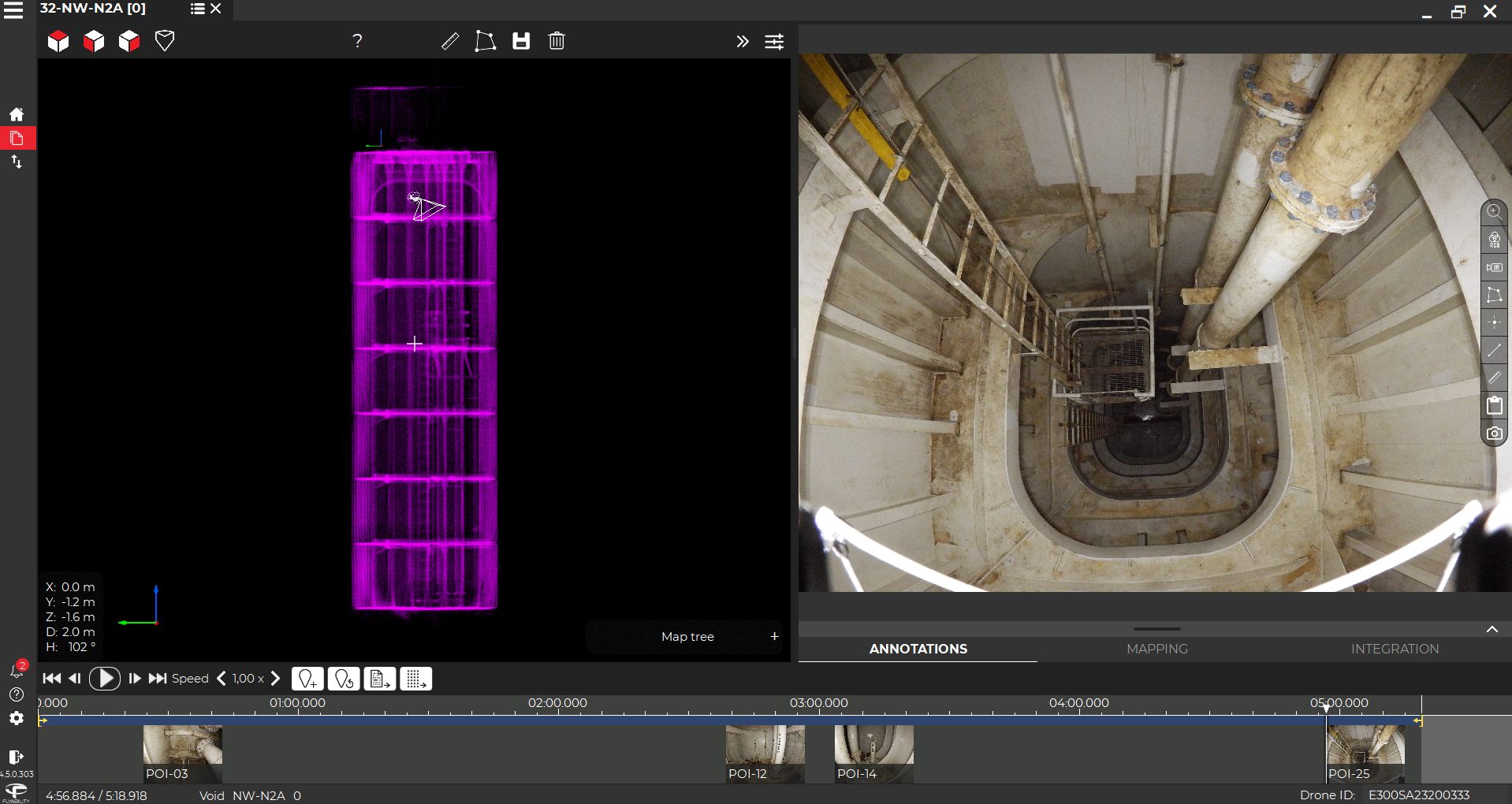

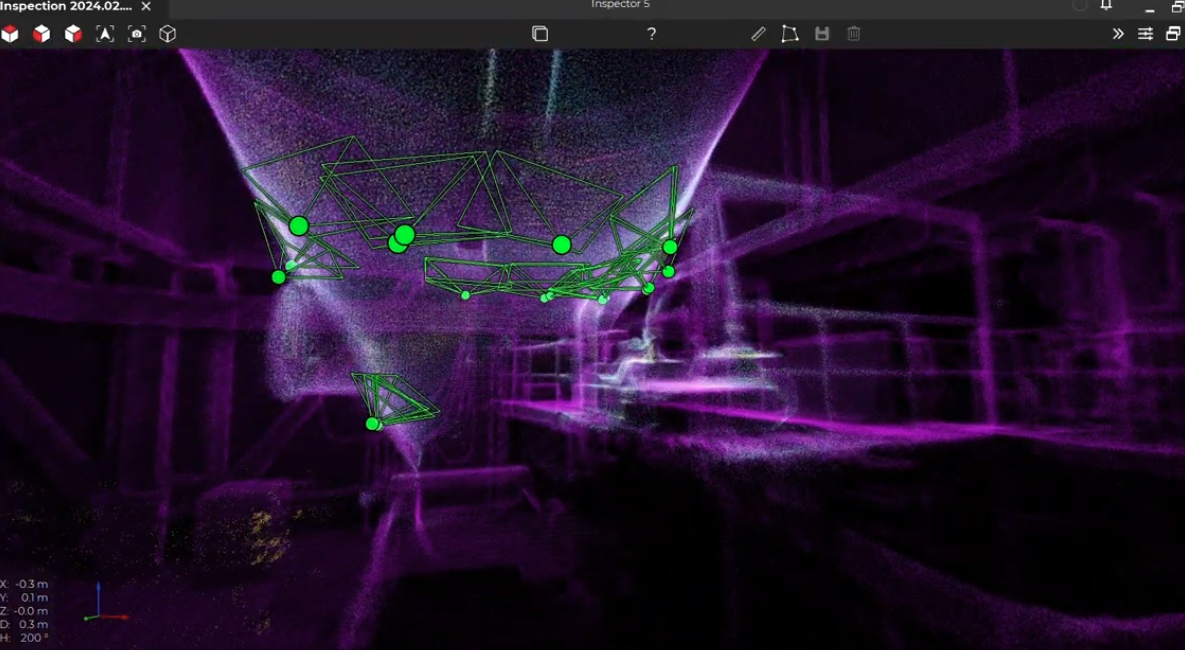

4. User Interface and Control The inspection view is accessible through a ground control station (GCS), which generates:

|

Outcomes

Voliro T produced highly efficient data, streamlined inspection workflows and radically improved safety.

Requirement of 615m3 of scaffolding was eradicated.

It cut down 400 man-hours in installation and dismantling processes.