Overview

External inspections of operational storage tanks must be conducted monthly to detect any signs of deterioration such as leaks, stains, bulges, or deformations. These checks include roofs, walls, bottoms, and attached components like pipes and ladders.

Challenges

- Manual inspections are time-consuming and often risky for human workers.

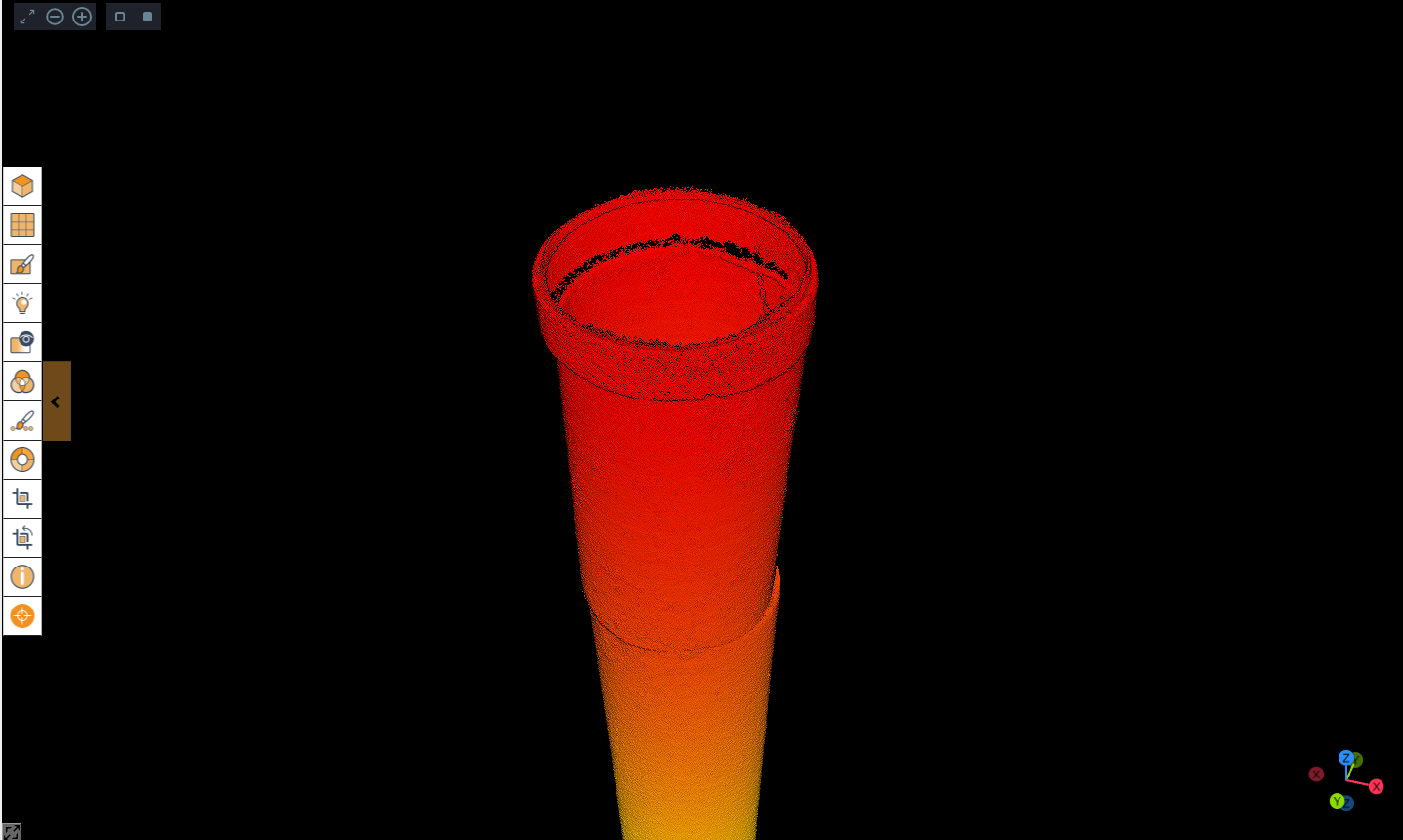

- Identifying areas with less than 50% thickness is critical per STI SP001 standards.

- Inspections must be swift following events like storms or visible structural damage.

- Traditional thickness measurements can lack precision and take significant time.

Solution

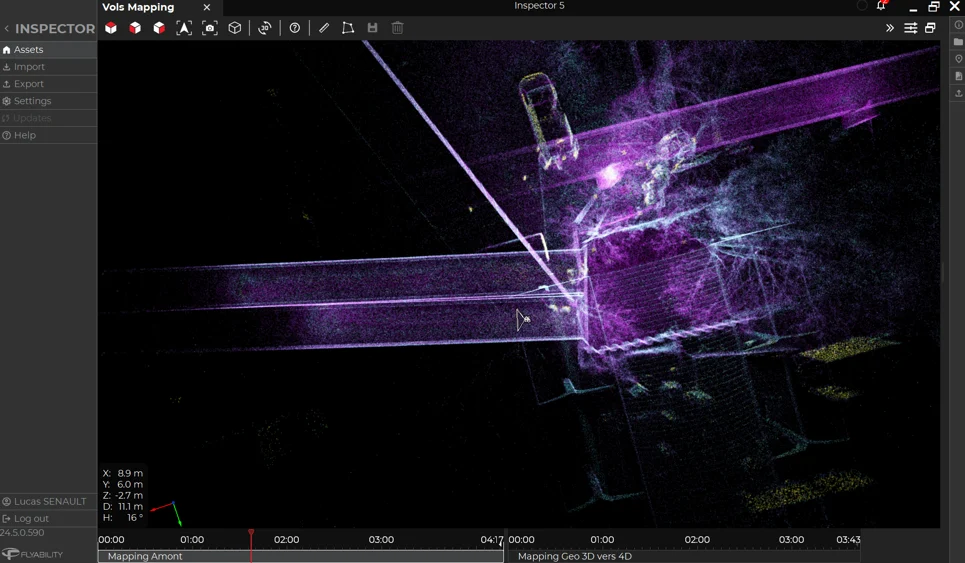

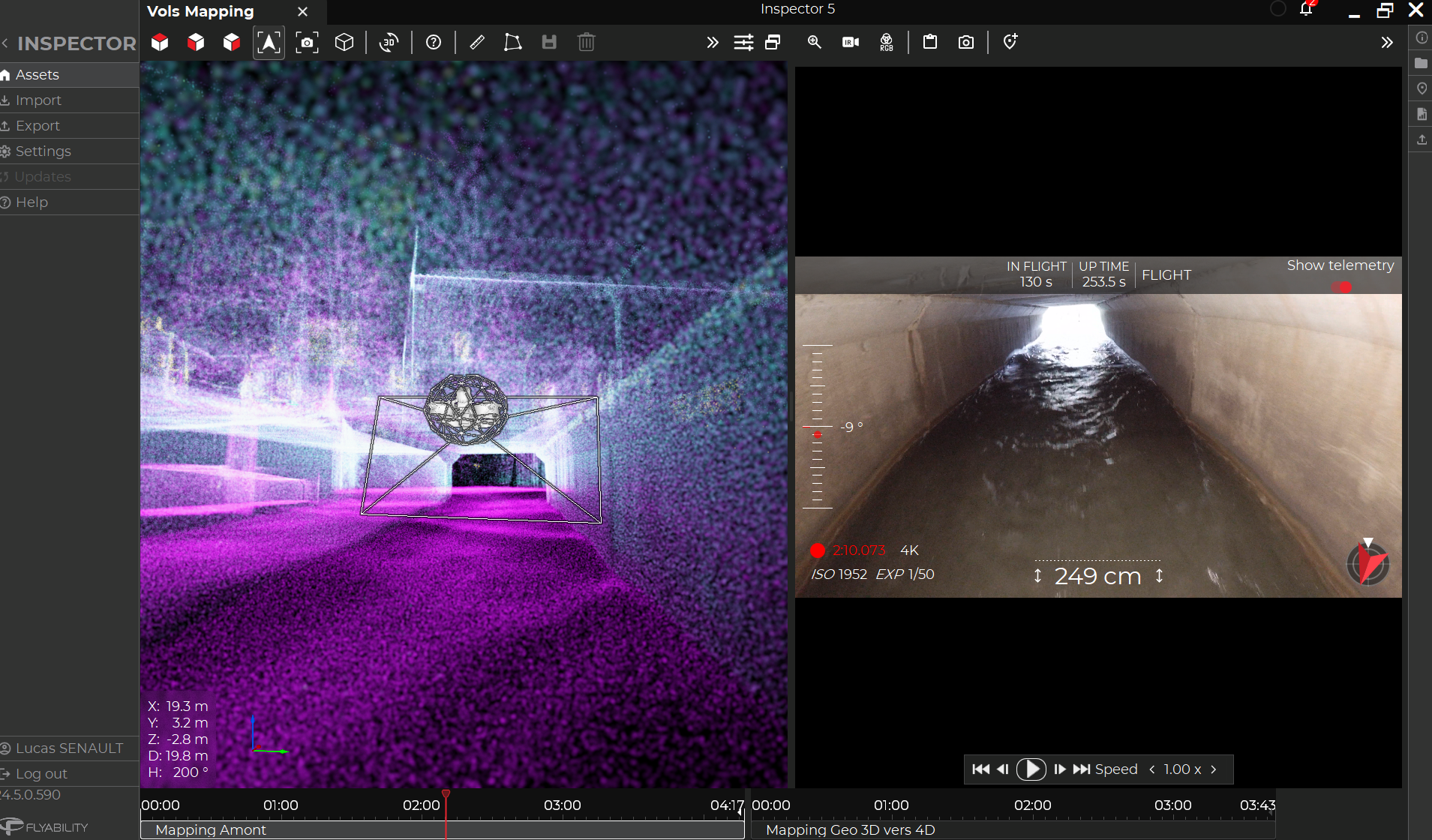

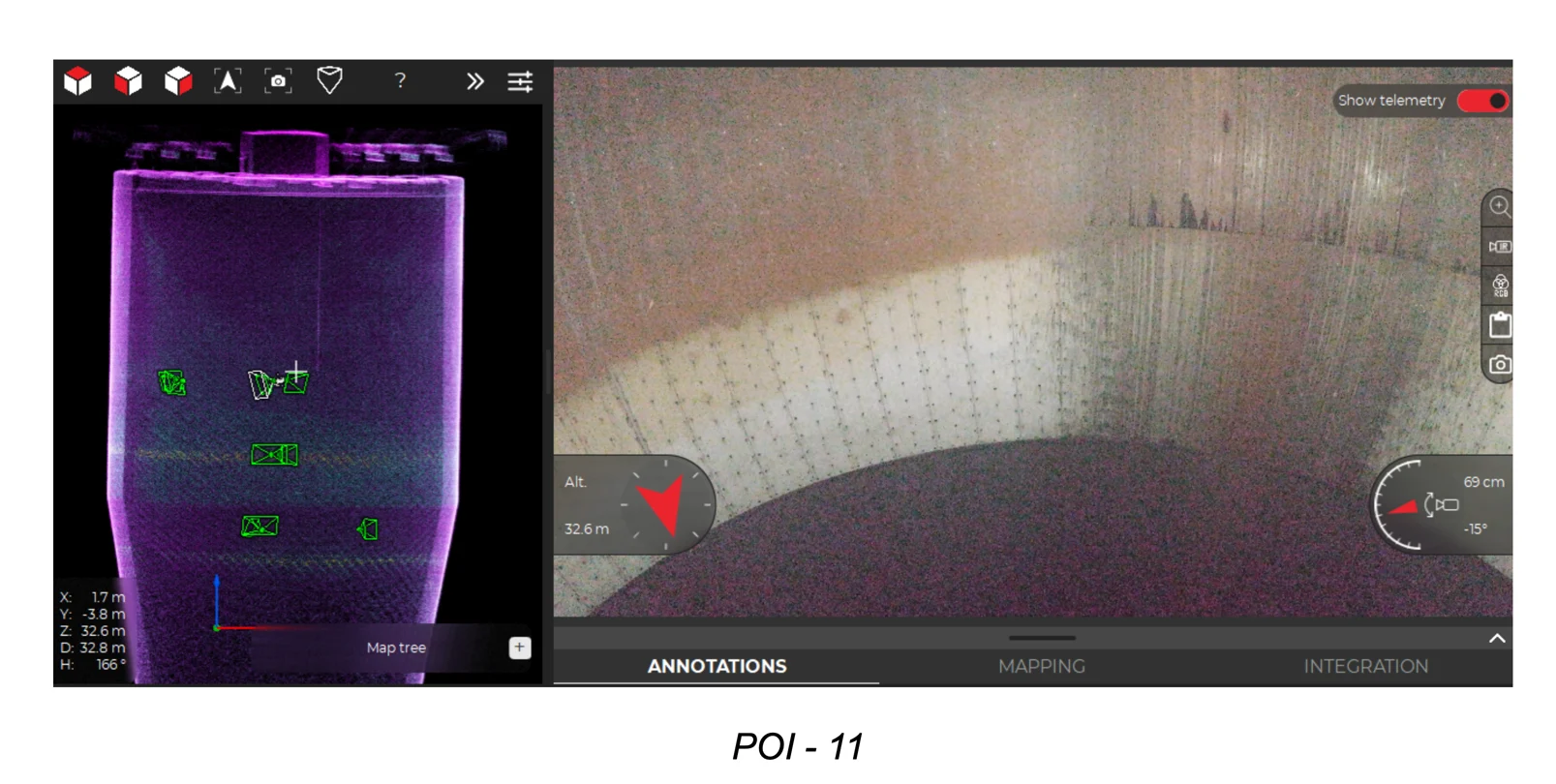

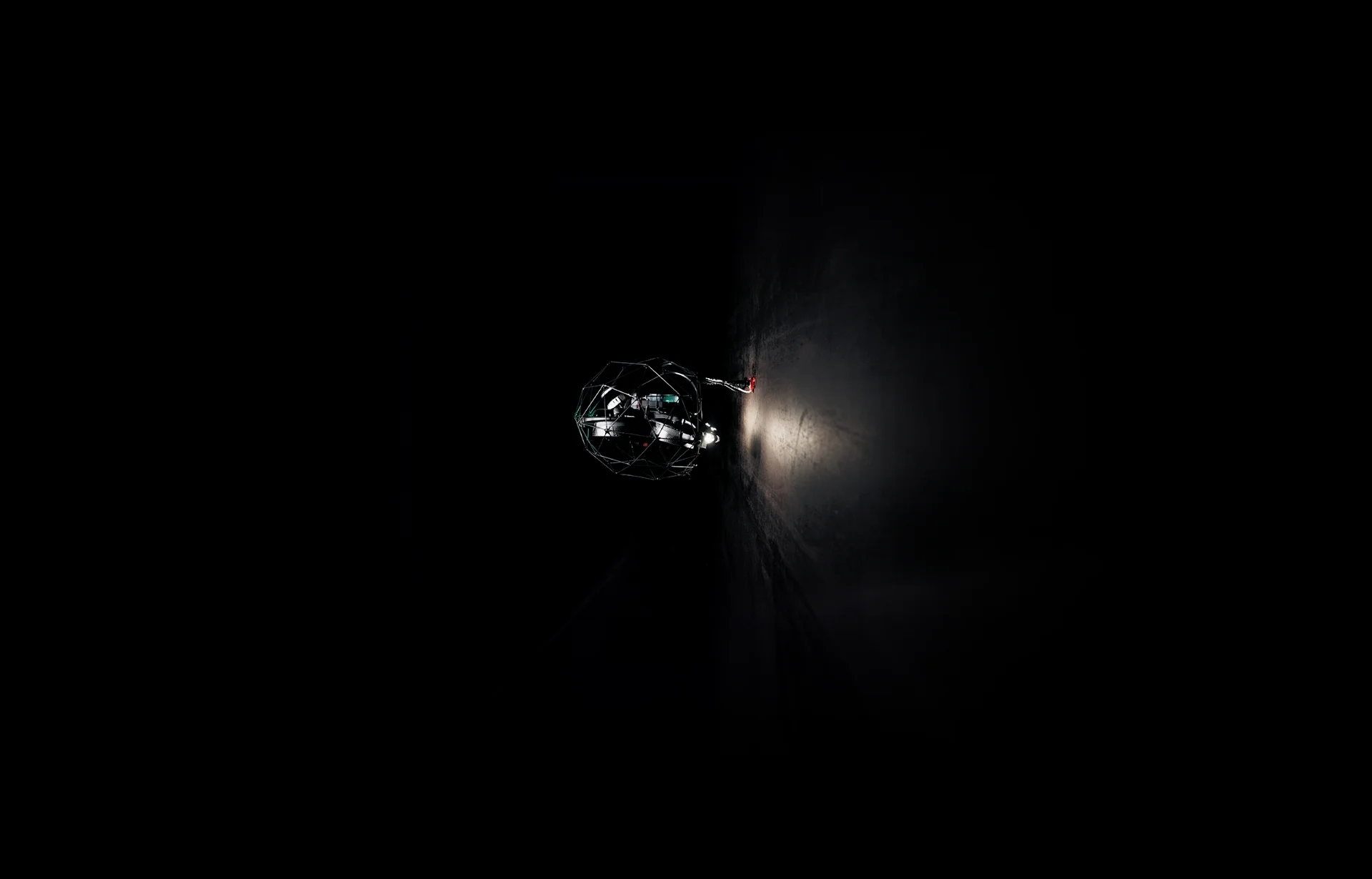

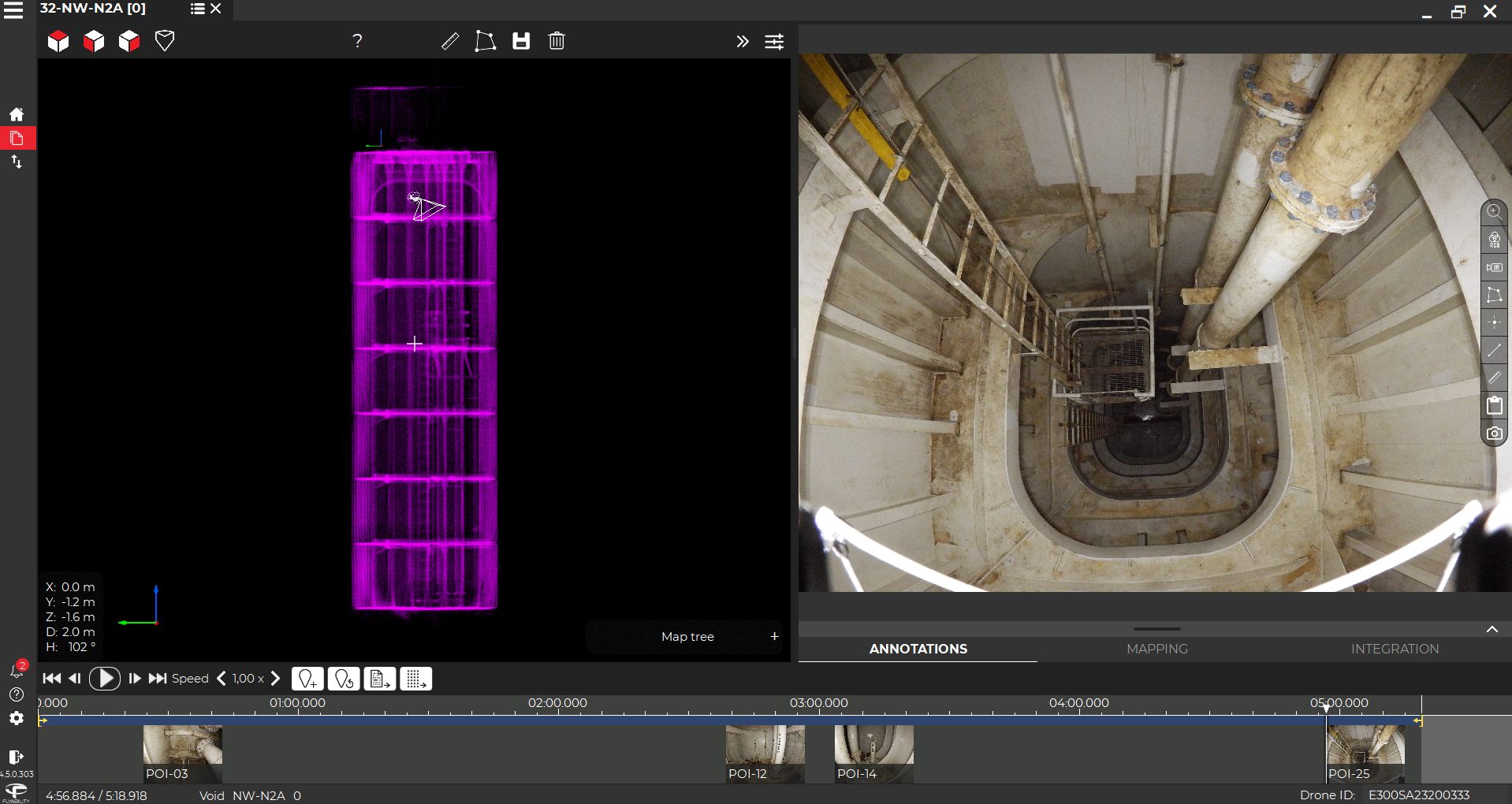

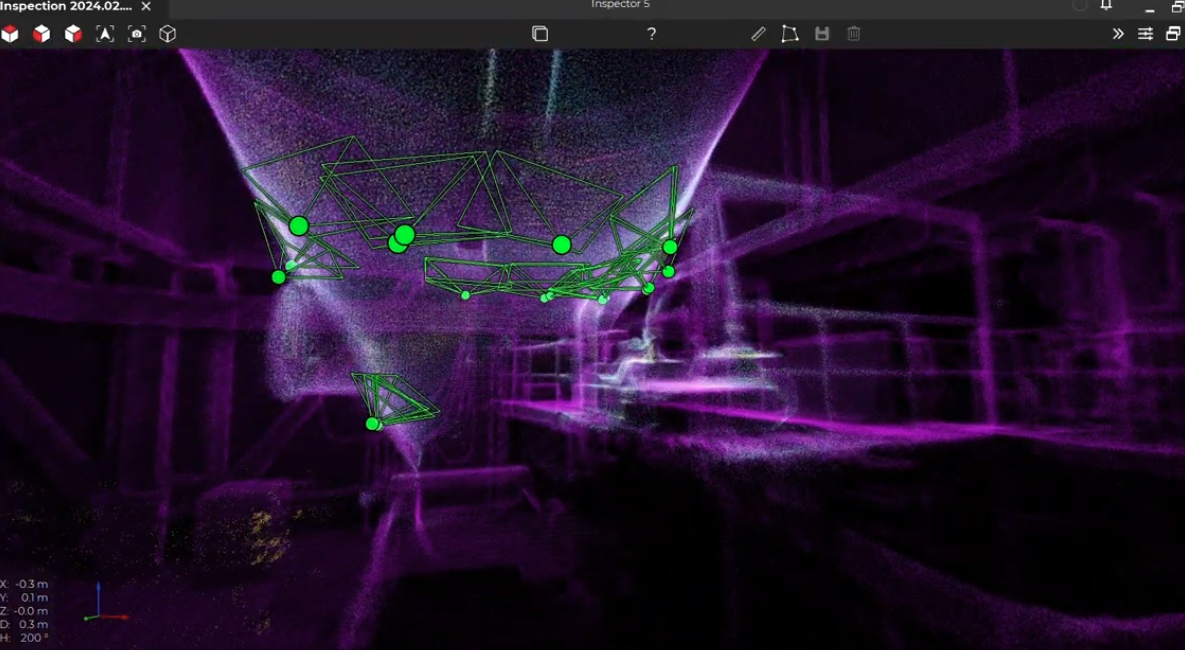

Using drones like the Voliro T, inspections were carried out efficiently with onboard ultrasonic thickness gauges and high-resolution imaging. These drones enabled accurate and rapid assessments without the need for scaffolding or shutdowns.

Outcome

- Faster Inspections: 5 tanks were fully inspected in a single day.

- Efficiency: A single tank was reviewed in just 75 minutes.

- Comprehensive Data: 8 vertical or horizontal scanlines captured detailed visual and ultrasonic data.

- Accurate Thickness Assessment: Drones provided high-resolution UT data for structural analysis.

Conclusion

Drone-assisted inspections, particularly with the Voliro T, deliver exceptional speed, safety, and precision. These inspections allow industrial facilities to maintain compliance and integrity while minimizing downtime and operational risks.