Overview

Explore how Elios 3 inspected 2,000 feet (600 meters) of piperacks, checking insulation, valves, and material condition. The drone completed the job in just 2 days and cut inspection costs by 60% compared to traditional methods.

Piperacks are the backbone of fluid and material transport in industrial plants. This high-scale infrastructure organizes and stabilizes pipelines for effective operation in industries such as oil refineries and power plants.

Regular and thorough inspections are vital for these piperacks to recognize possible complexities like sagging, corrosion, structural fatigue, and leaks early.

The Challenge

The complexity of piperack infrastructure poses significant challenges for inspection and maintenance:

- Due to its raised nature, specialized equipment like cherry pickers or scaffolding (often 50 feet high) is required.

- Workers are exposed to significant risk—falls and electric hazards are common threats.

- Manual inspections are slow, risky, and can interrupt ongoing site operations.

The Solution: Elios 3 Drone

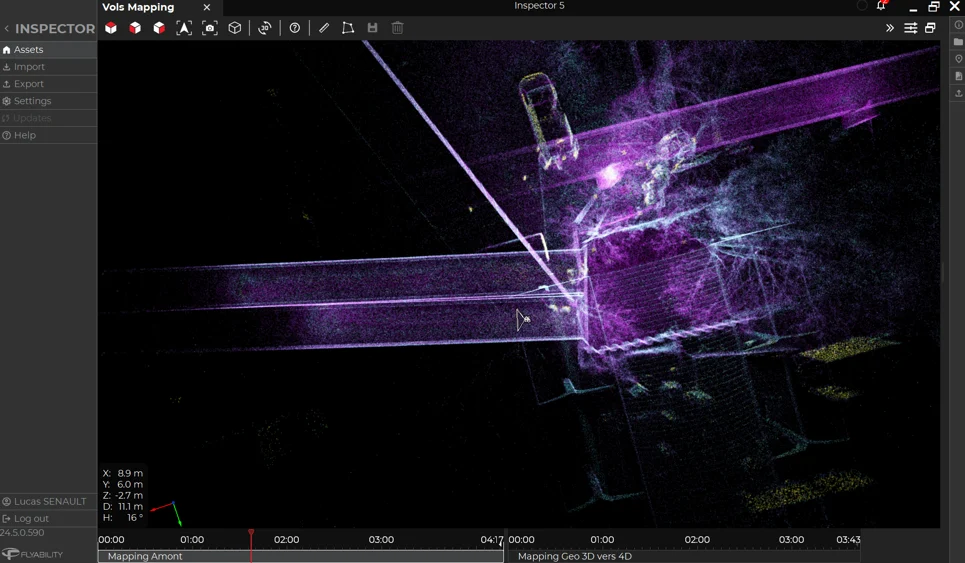

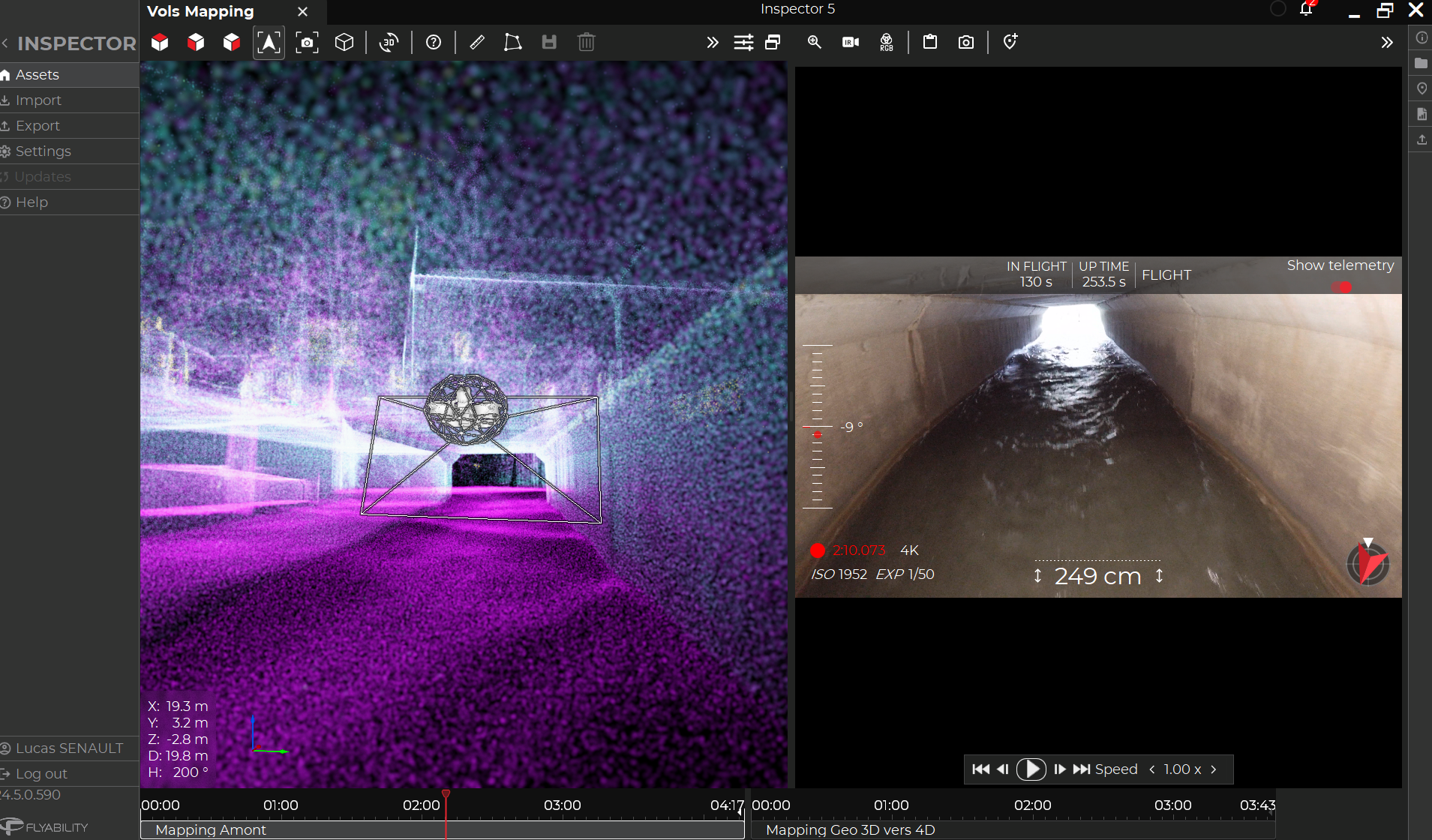

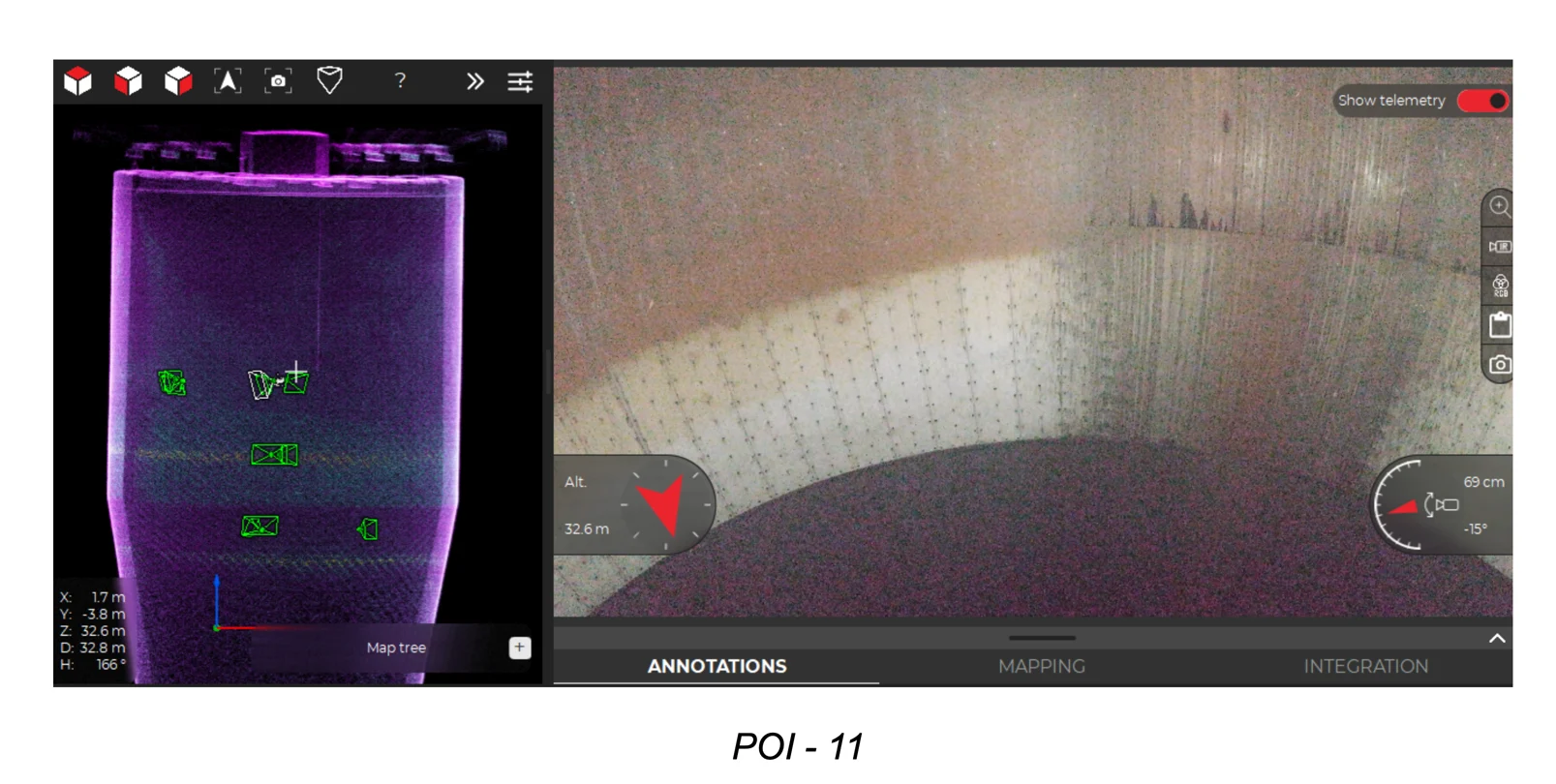

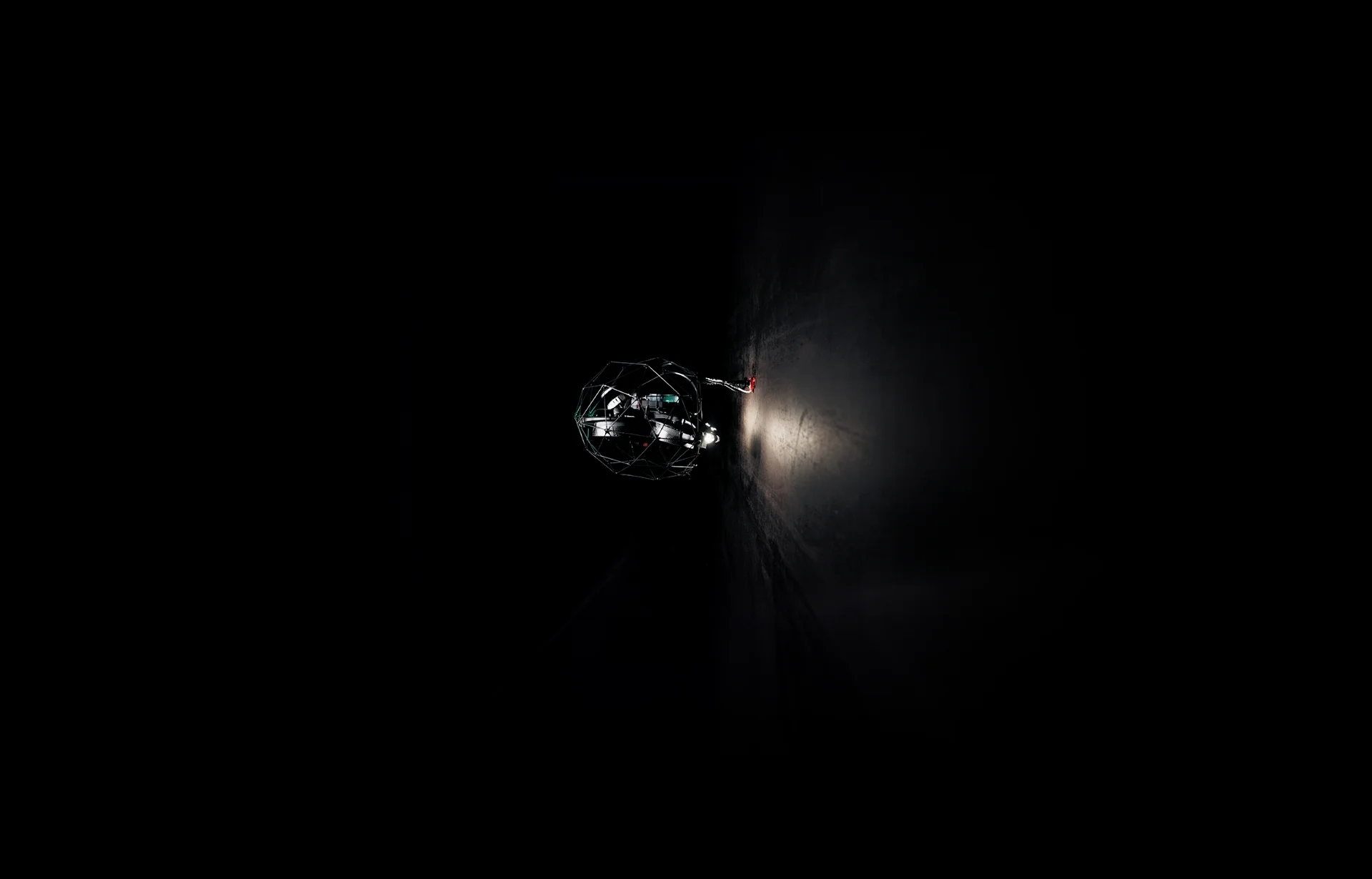

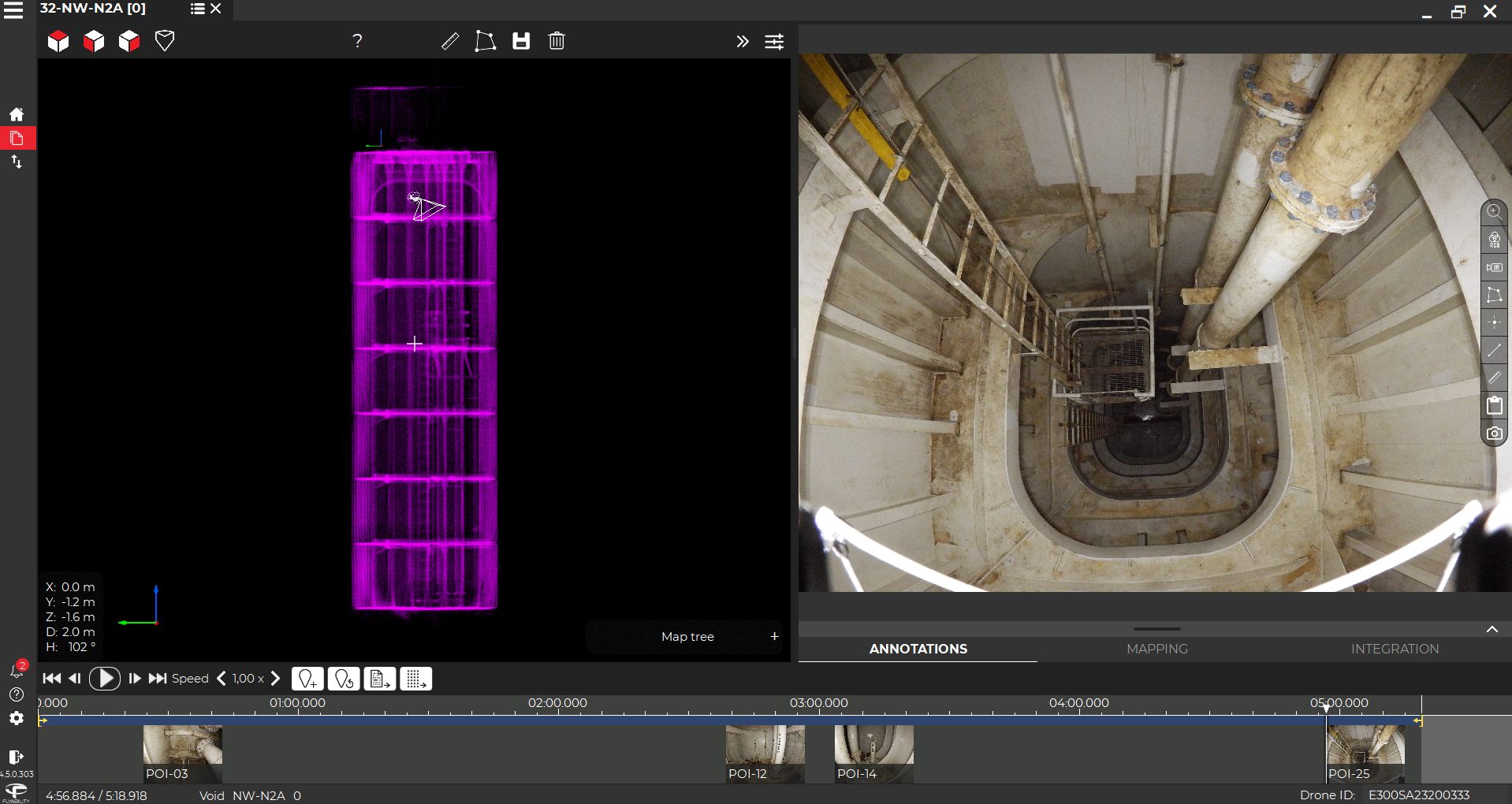

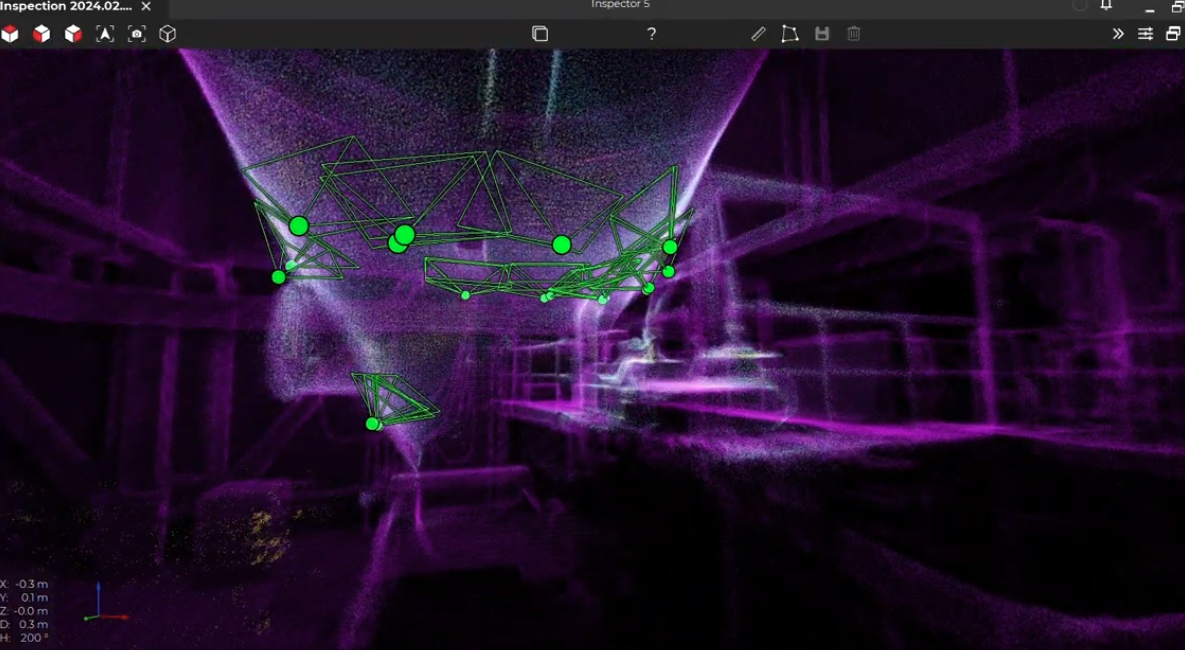

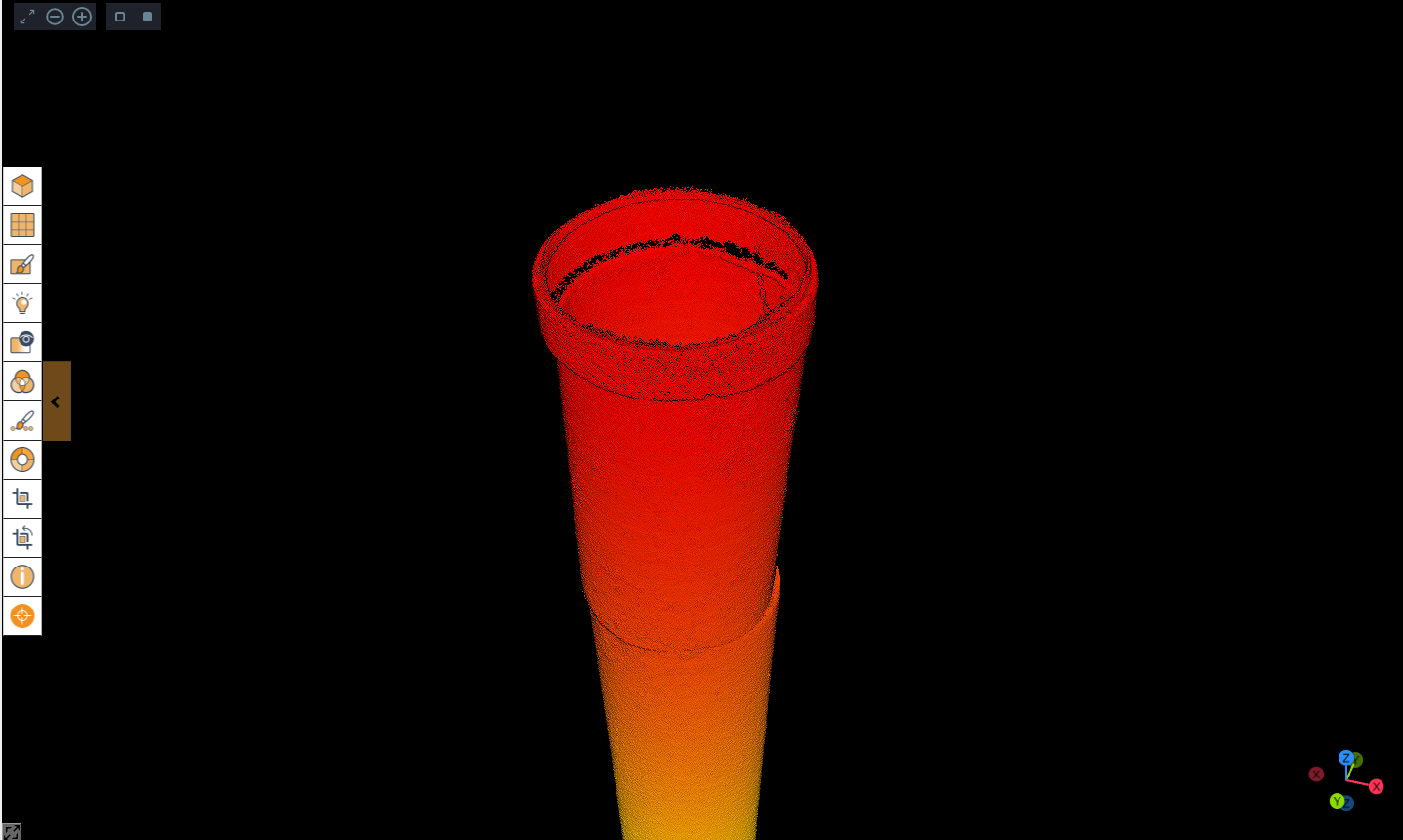

By leveraging Birdseye’s drone-based solution featuring Flyability’s Elios 3, 2,000 feet (600 meters) of pipe racks were inspected safely and efficiently. Thanks to built-in 4K cameras and a LiDAR scanner, high-quality data was collected without endangering workers.

The Outcome

| Benefit | Details |

|---|---|

| Easy Access | The drone flew directly into hard-to-reach areas, including tight gaps between pipes. |

| Safety | Its protective cage allowed close-proximity inspection with zero worker exposure to hazards. |

| Speed | Completed in just 2 days using 39 flights—much faster than traditional methods. |

| Cost Efficiency | Reduced inspection costs by 60%. |

| Visual Clarity | Captured 4K images and 3D LiDAR maps for accurate damage detection (e.g., corrosion, insulation failure). |

Future-Proof Your Inspection with Elios 3

Birdseye’s specialized drone services and advanced platforms like the Elios 3 are redefining how industrial maintenance is conducted. By minimizing risks, reducing costs, and enabling compliance with smart, data-driven inspection strategies, Elios 3 future-proofs industrial asset monitoring like never before.