Overview: Power Station Inspection Complexity

Power stations are big, complex, and contain hazardous environments. This makes traditional manual inspections both challenging and risky. Since 2016, the power station has been leveraging outdoor drones for inspections.

Challenges Faced

Hazardous Environments: Traditional inspection requires the need for working at height or in confined spaces due to the complex structures of power stations. So workers are highly exposed to risks.

Time Consuming: Workers spend hours to put up the equipment for inspection and require significant investment.

Limited Indoor Drone Options: When outdoor drones were utilized, it depended on GPS for navigation making it hard to operate in areas where GPS signals were lacking. Due to potential collision hazards, outdoor drones were not suitable for use near sensitive facilities.

Inefficient Inspection Workflow: Multiple resources were required to conduct inspections effectively but Manual methods and traditional tools often caused delays.

Skepticism About Drone Viability: Some staff were not ready to allow drones for inspection as they believed it would not suit industrial applications.

Solutions

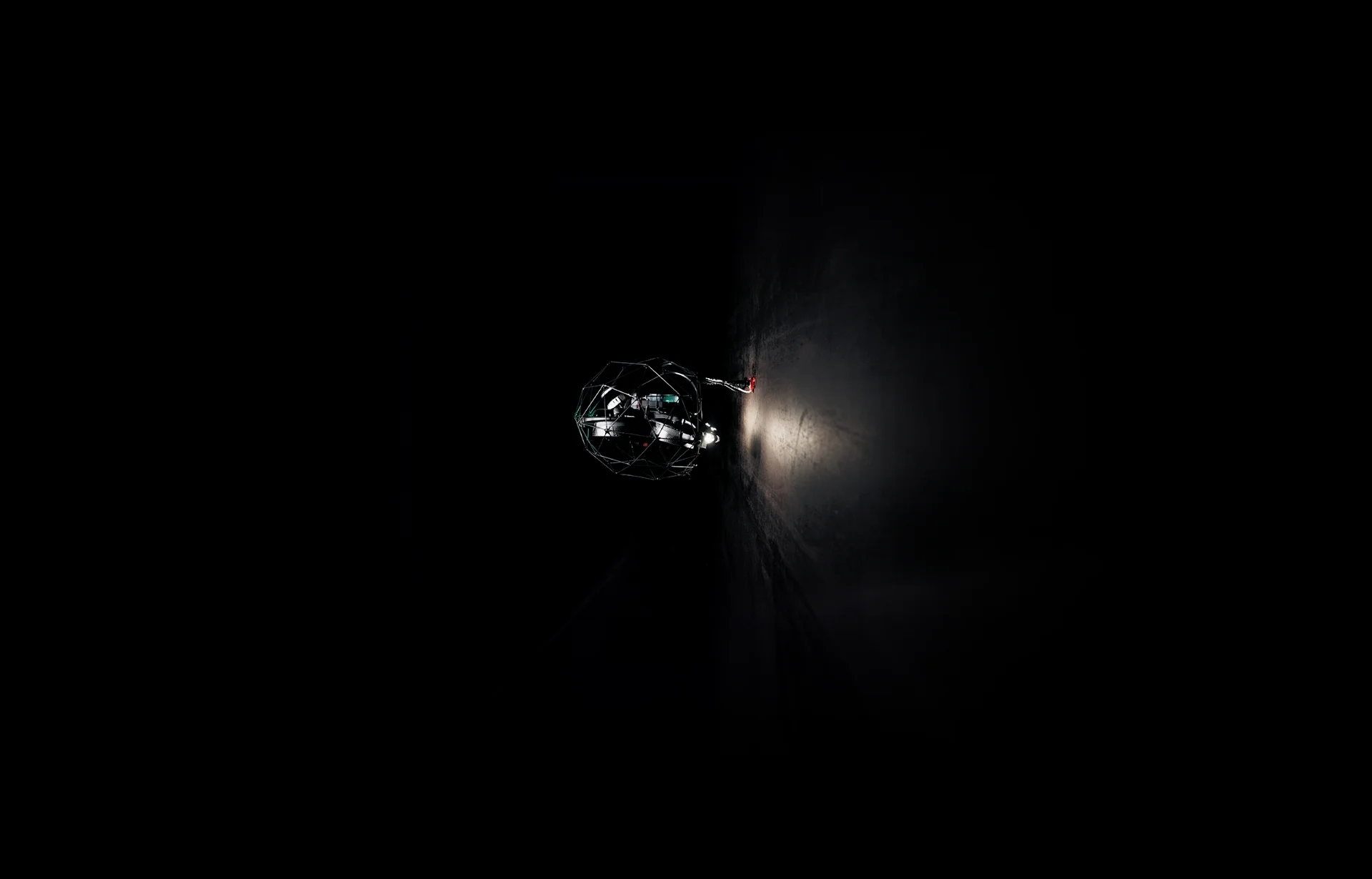

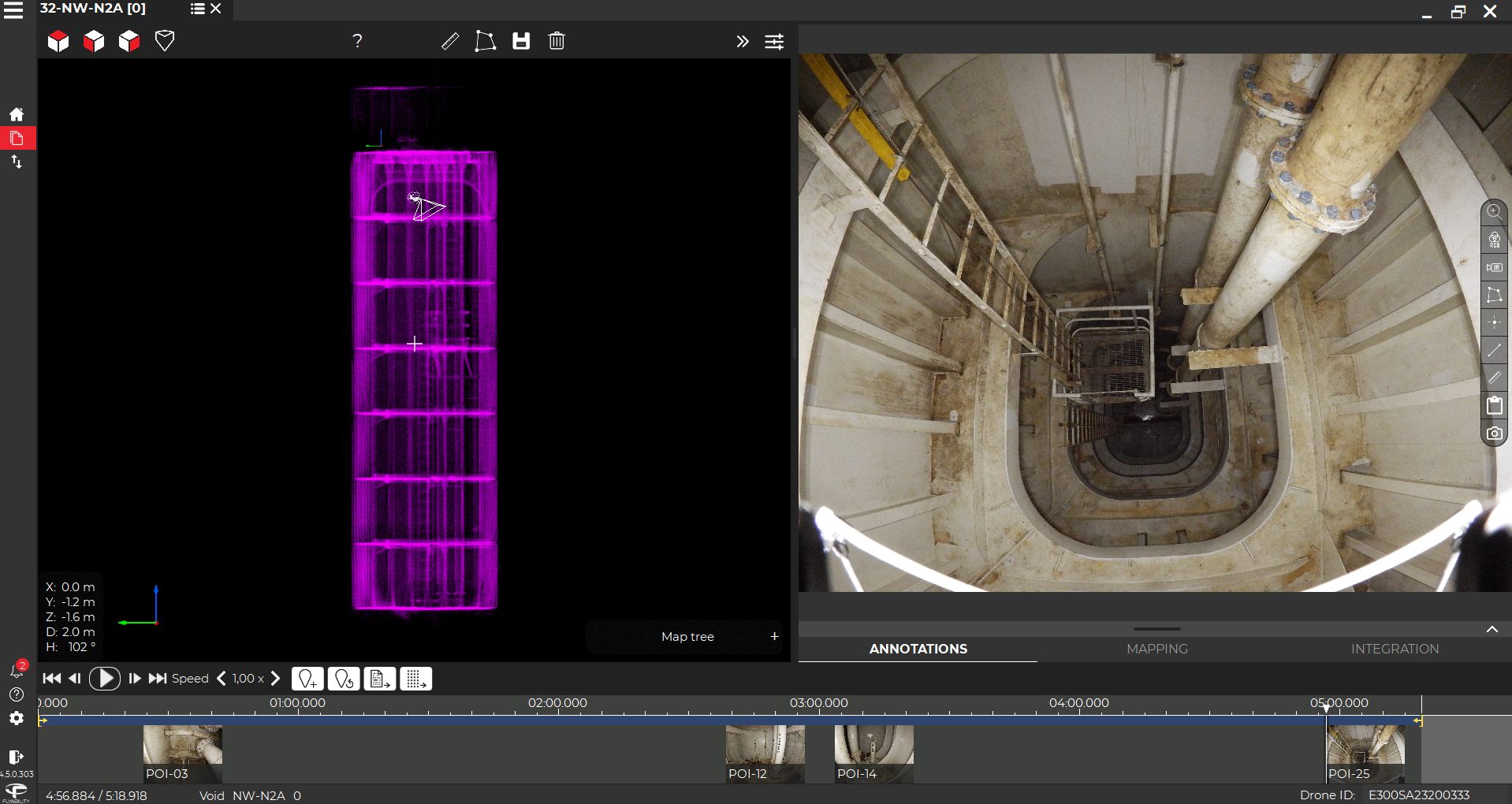

Elios 2 and 3 were used for the inspection process.

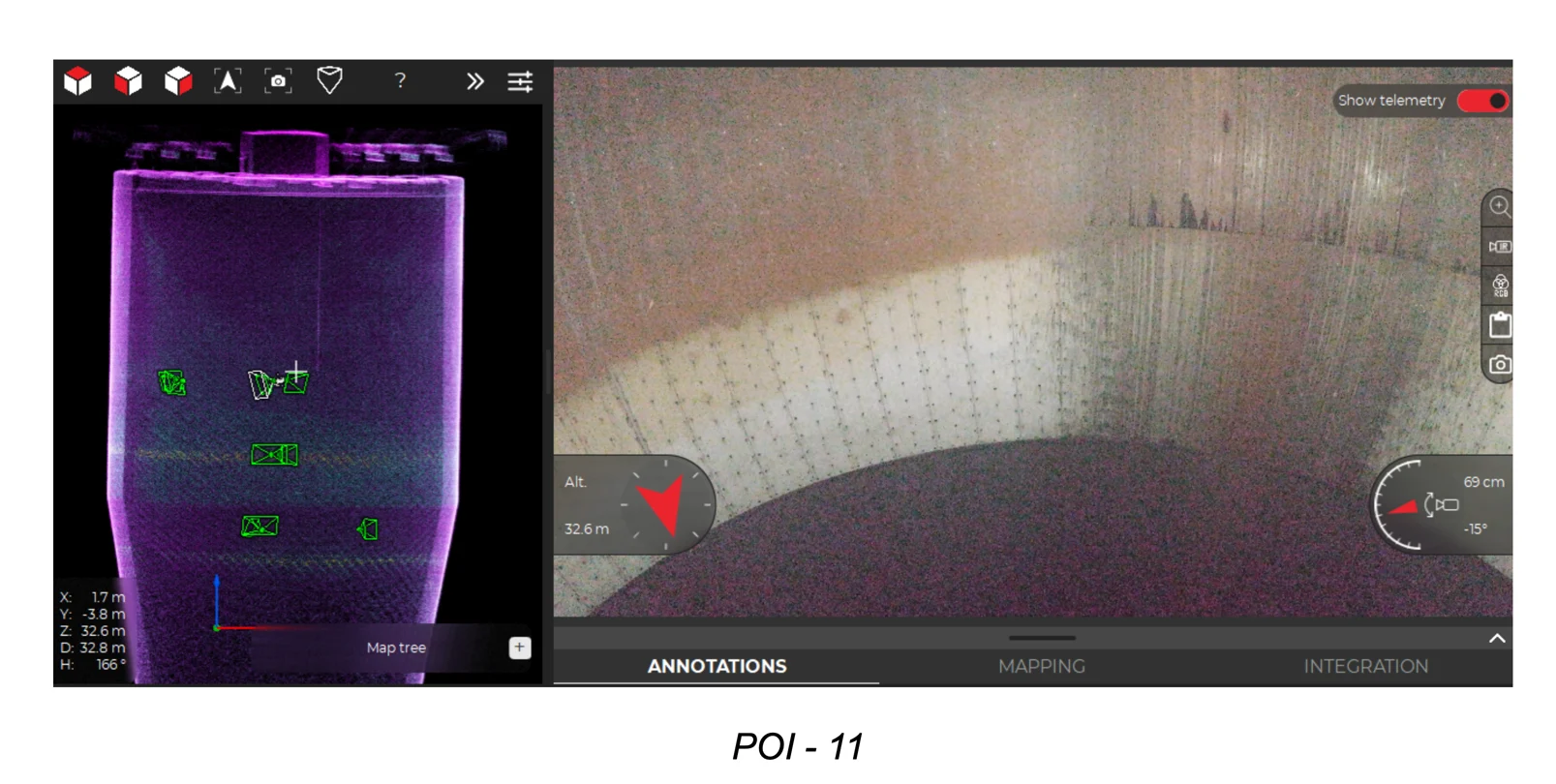

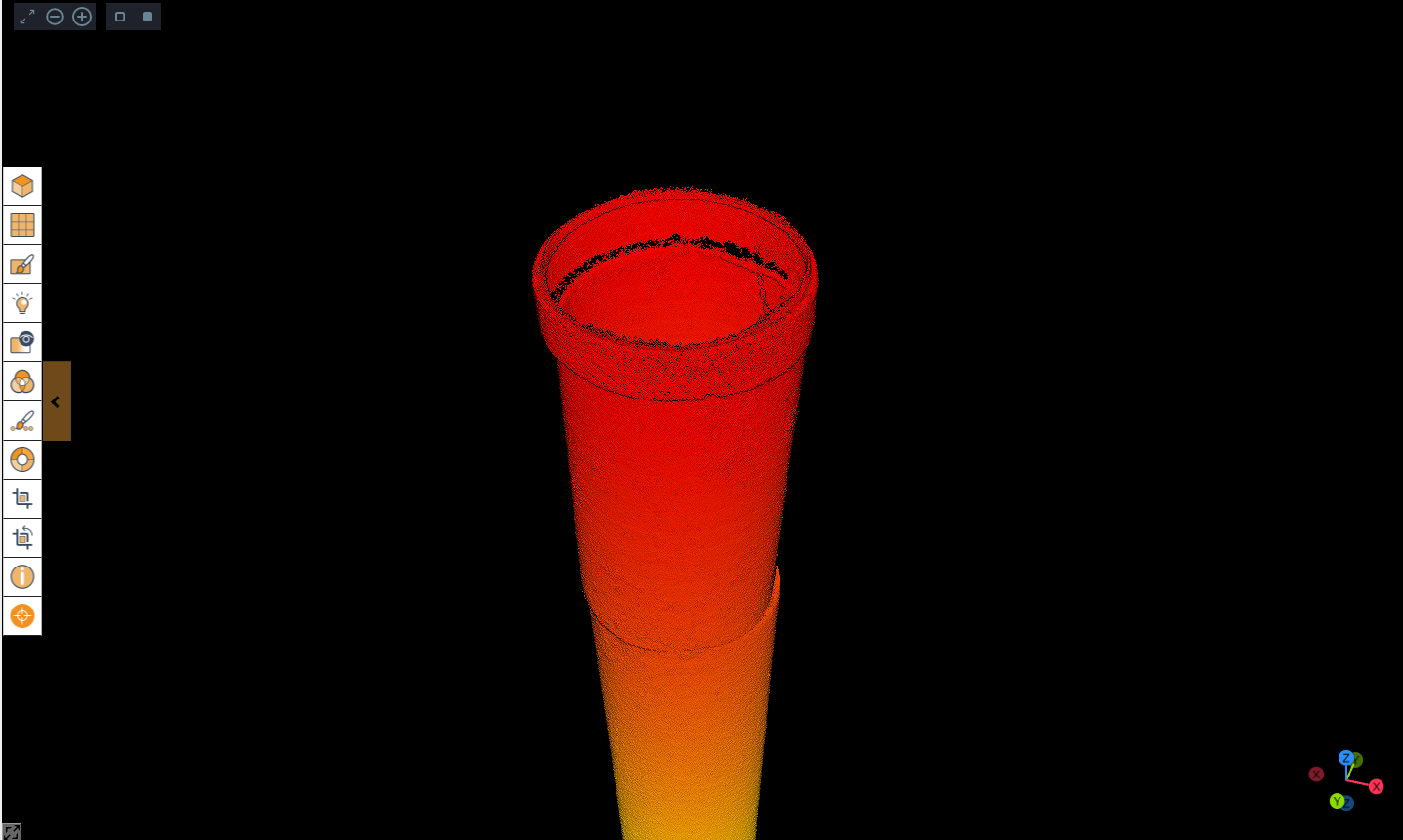

With Elios 2’s unique design and collision tolerance it paved the way for inspection of indoor stockpile measurements and boilers with a height of 30 meters. It also enabled simultaneous thermal and visual data collection.

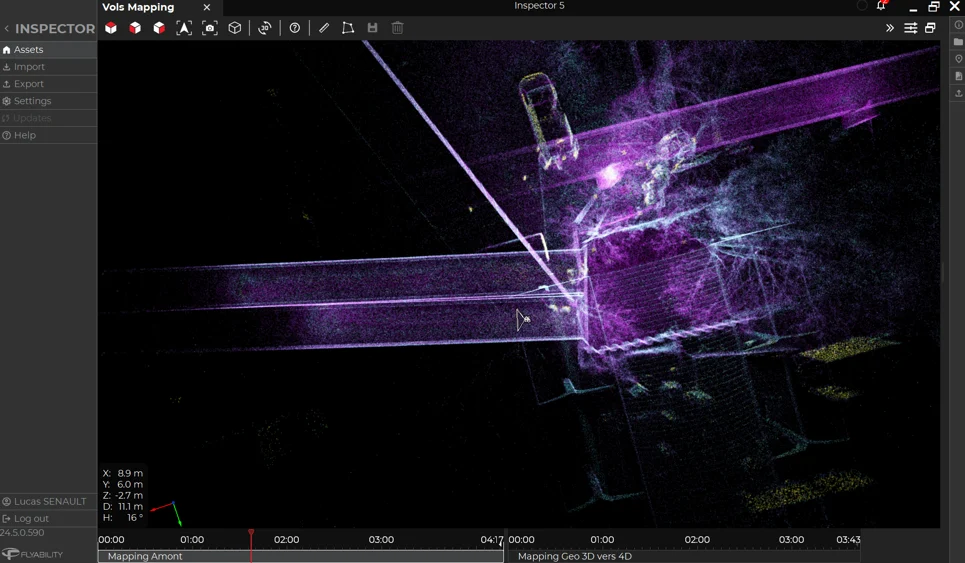

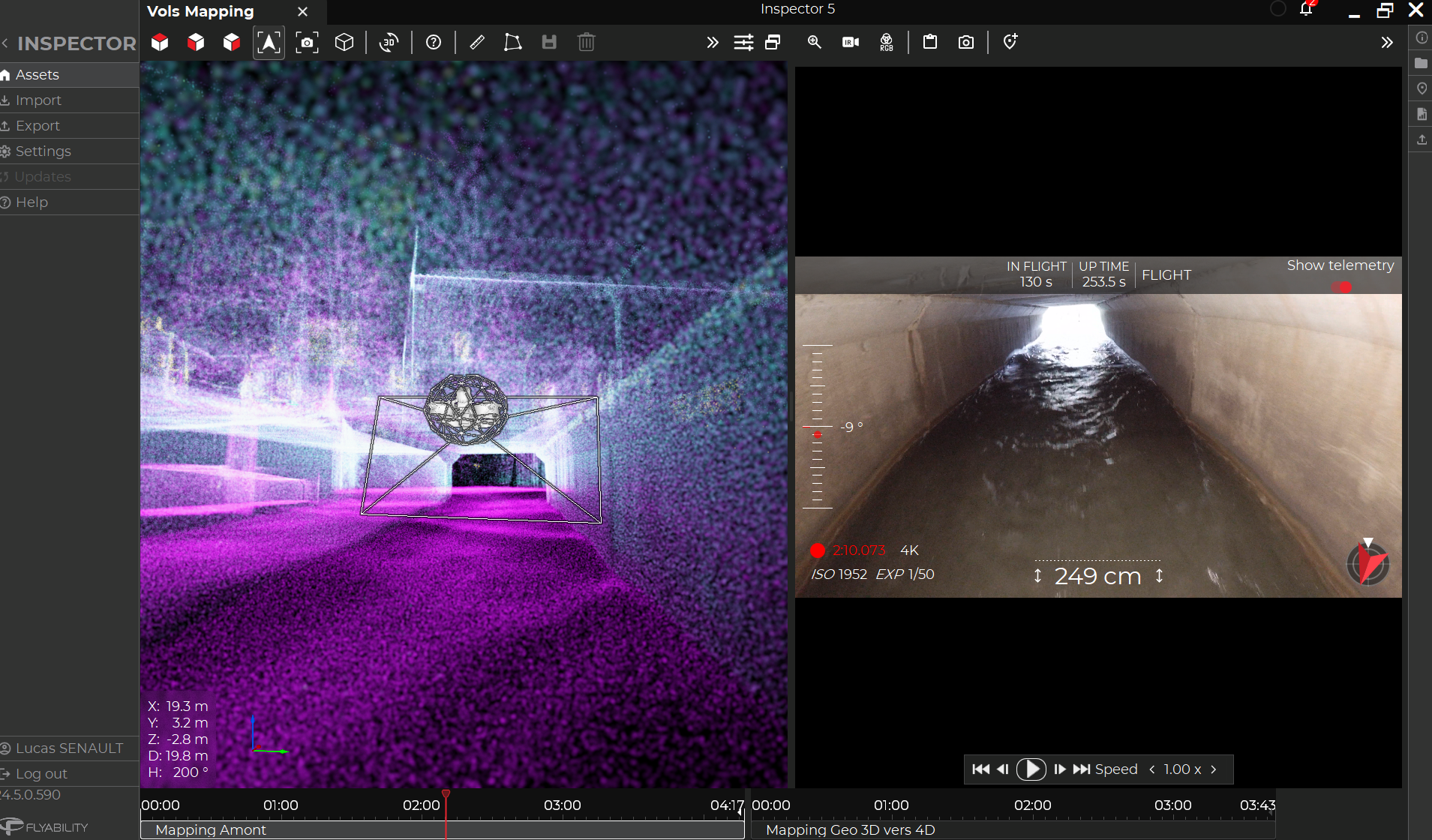

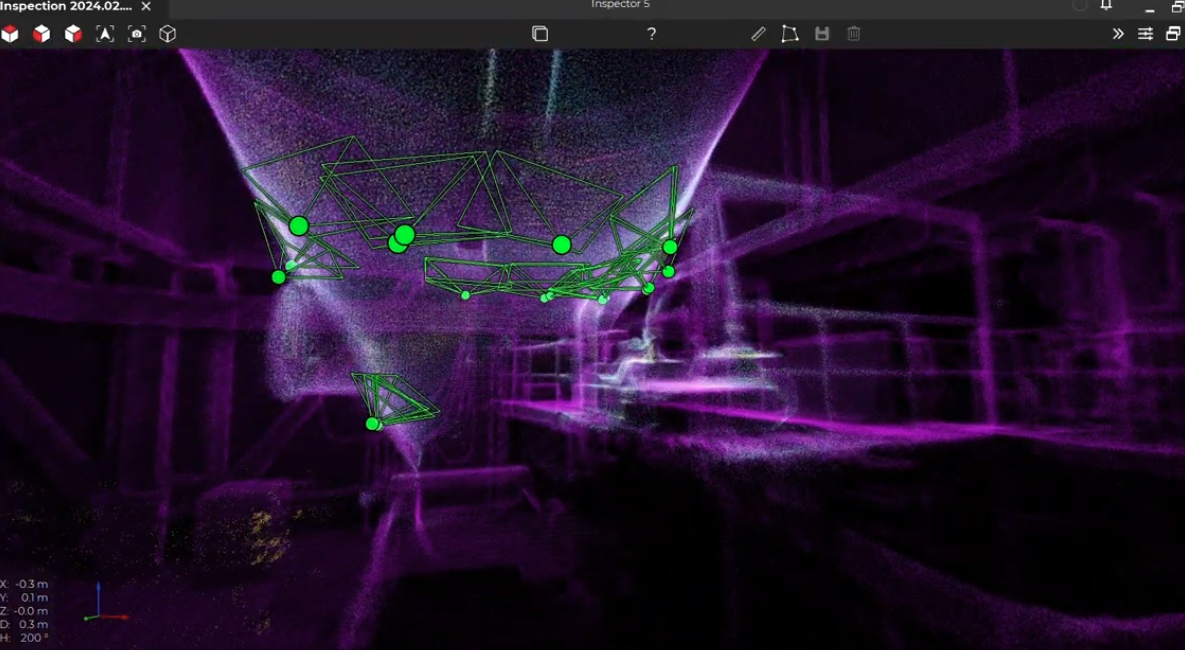

With the launch of Elios 3, because of its advanced features – LiDAR and visual payload, it was leveraged for faster, safer and streamlined inspection processes and to collect LiDAR data.

Outcome

- Drone-based inspections eliminate scaffolding and reduce downtime significantly.

- Elios drone completes scans quickly without draining or confined space entry.