Overview

Discover how Birdseye’s drone inspection services completed complex Cargo Oil Tank (COT) inspections in just one week.

Drone-based inspections are becoming the talk of the town in maritime safety and asset management. Continuous inspection of Cargo Oil Tanks in ships roughly occurs every 5 to 10 years to ensure the tanks can transport oil efficiently. As these tanks age, the frequency and complexity of inspections increase.

The Challenge

- Necessity of rafting, scaffolding, or rope access to reach different parts of the tank.

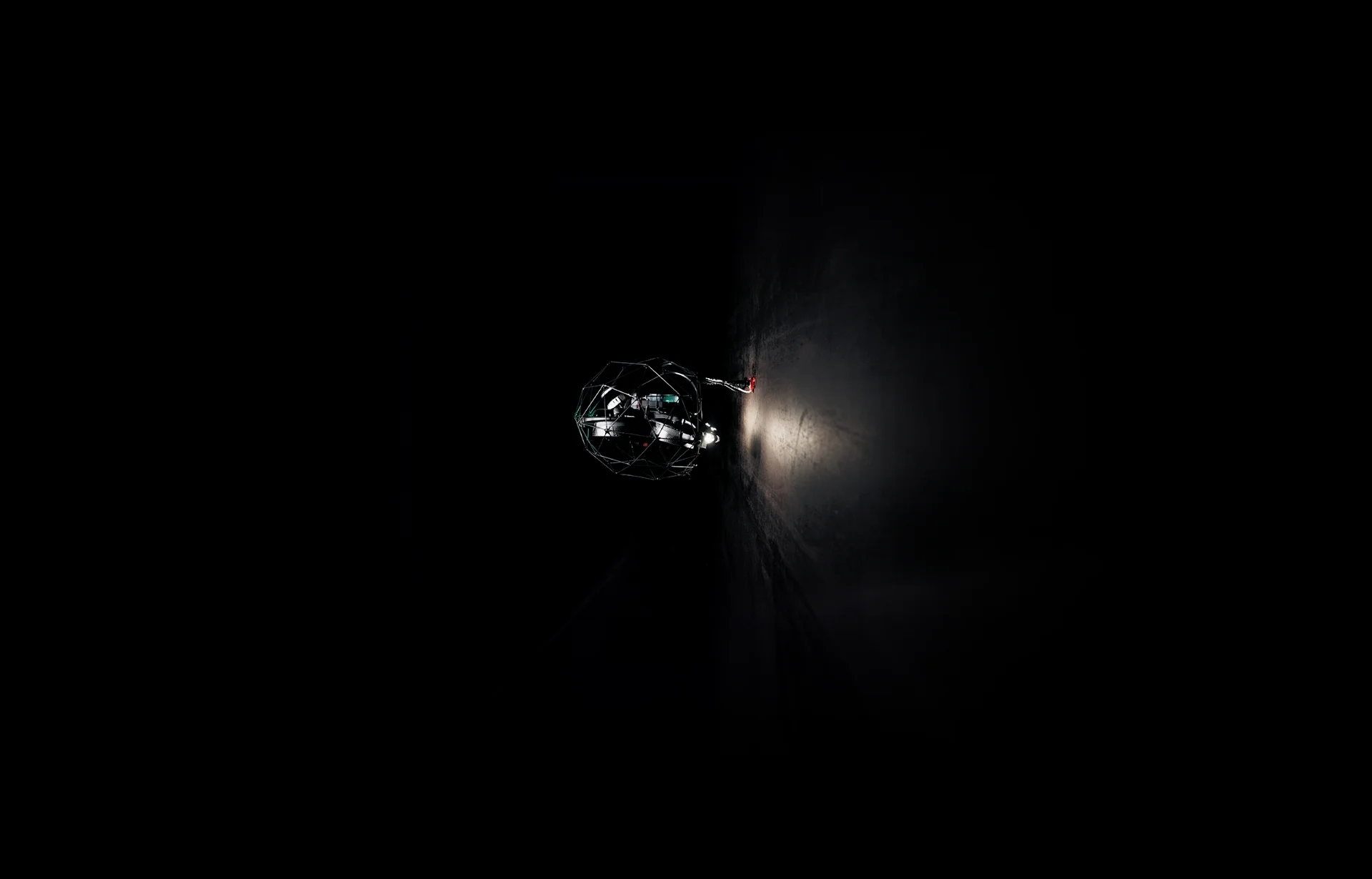

- Humans cannot enter the tank without a confined space entry permit.

The Solution

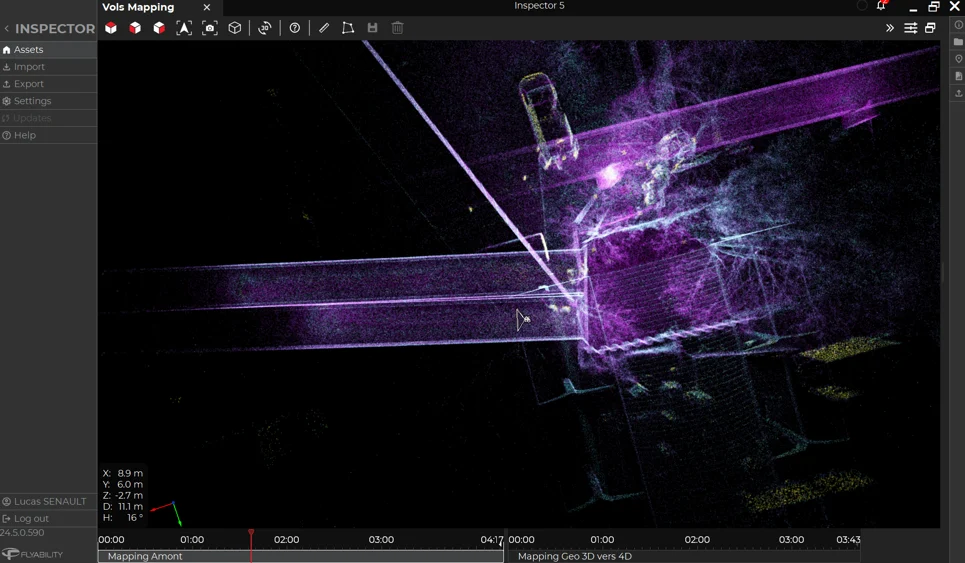

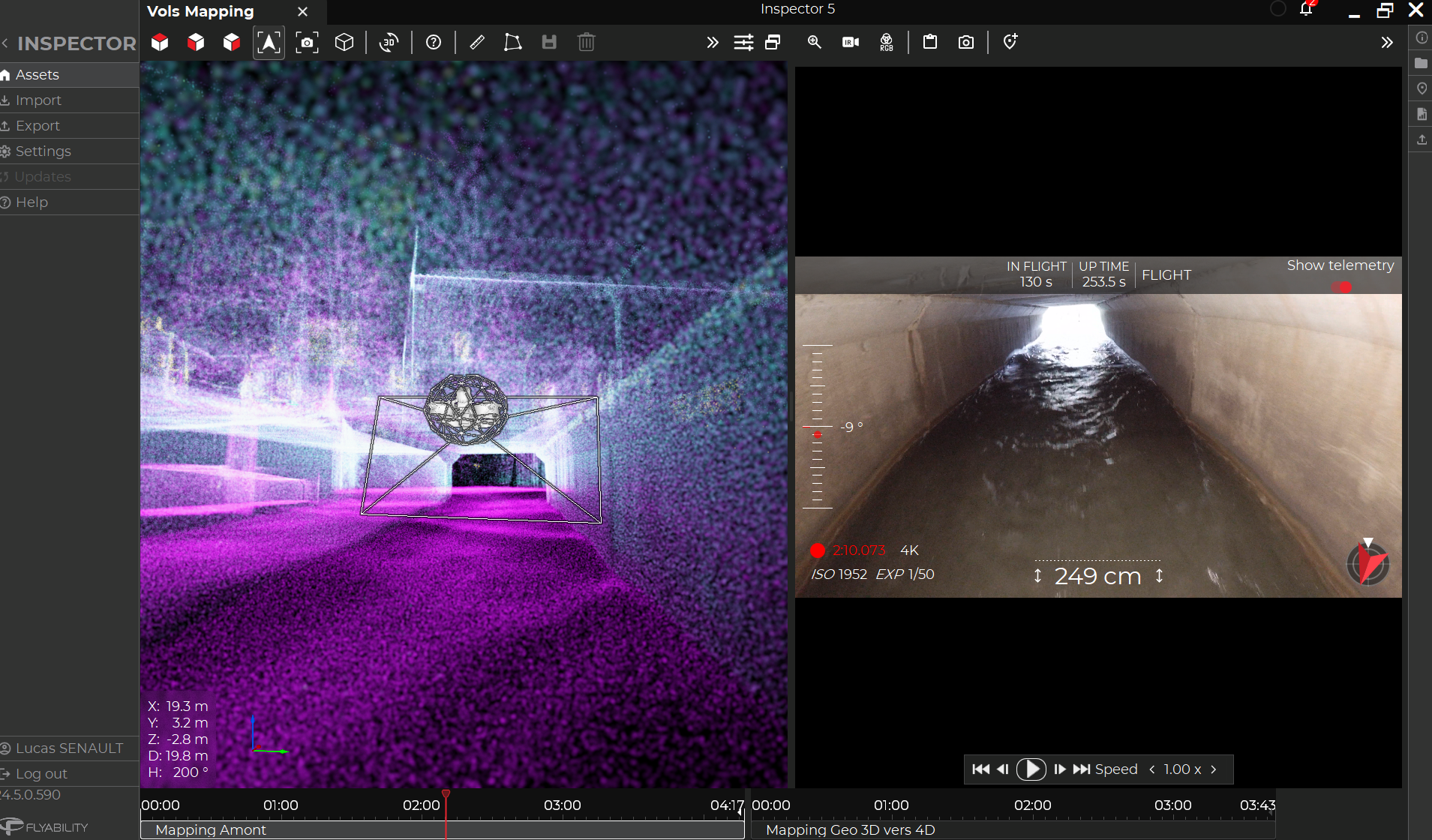

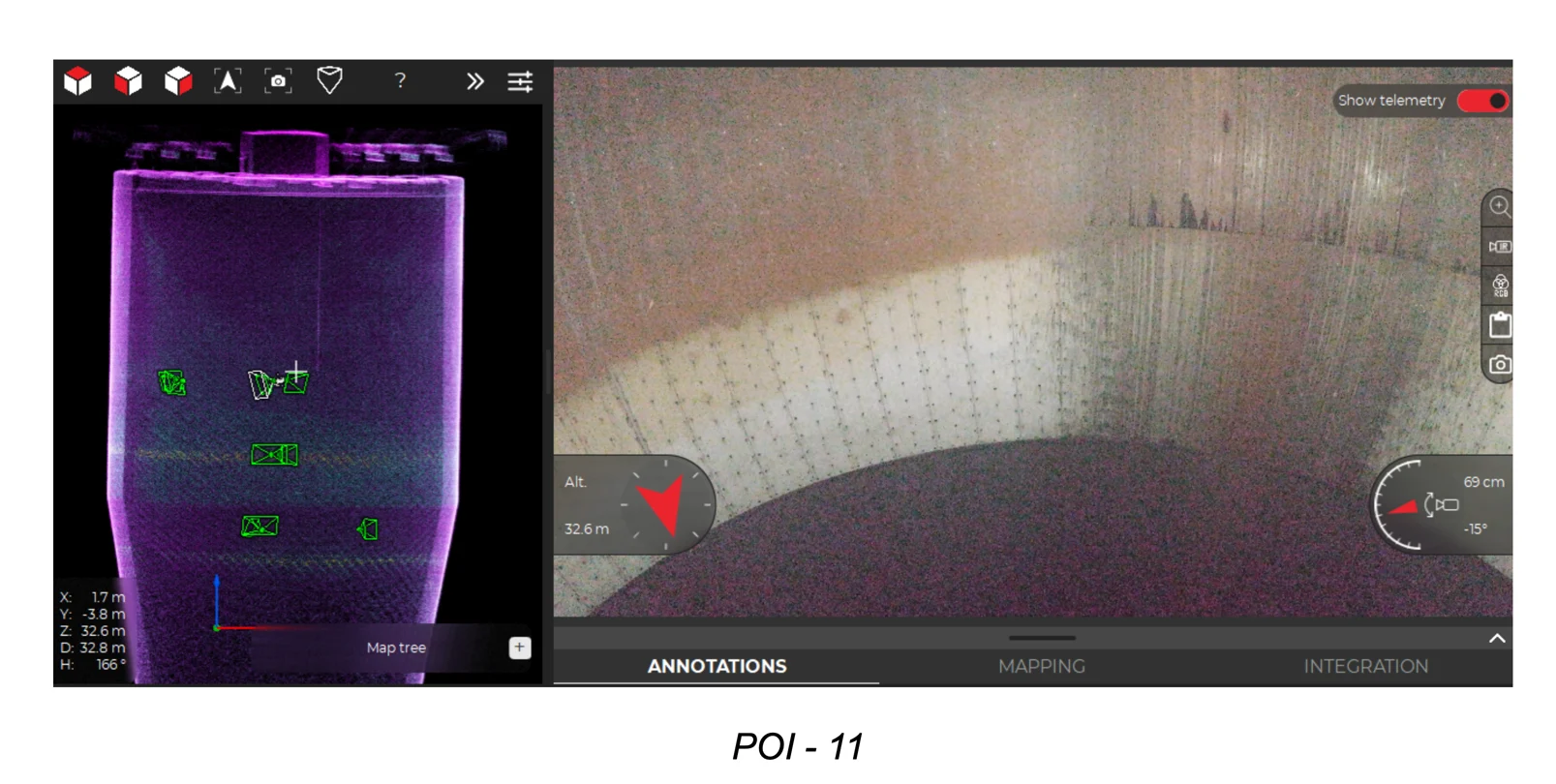

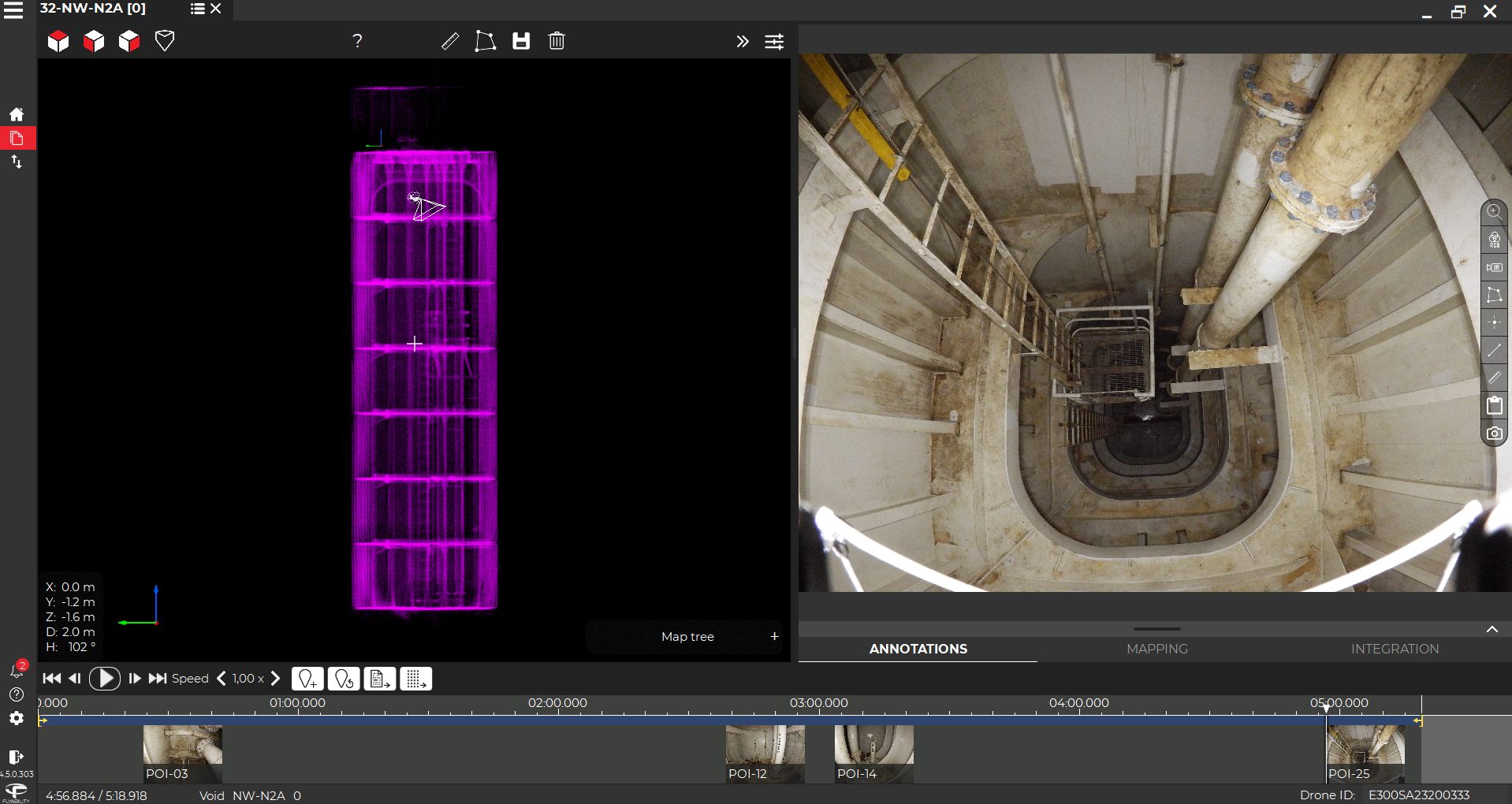

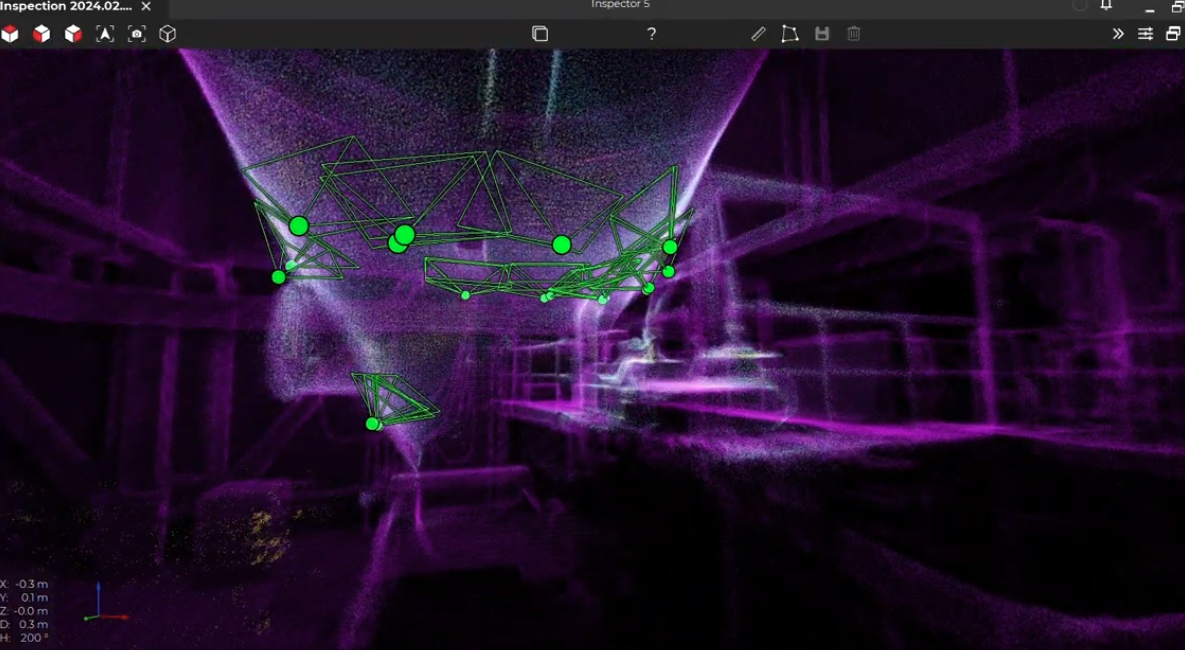

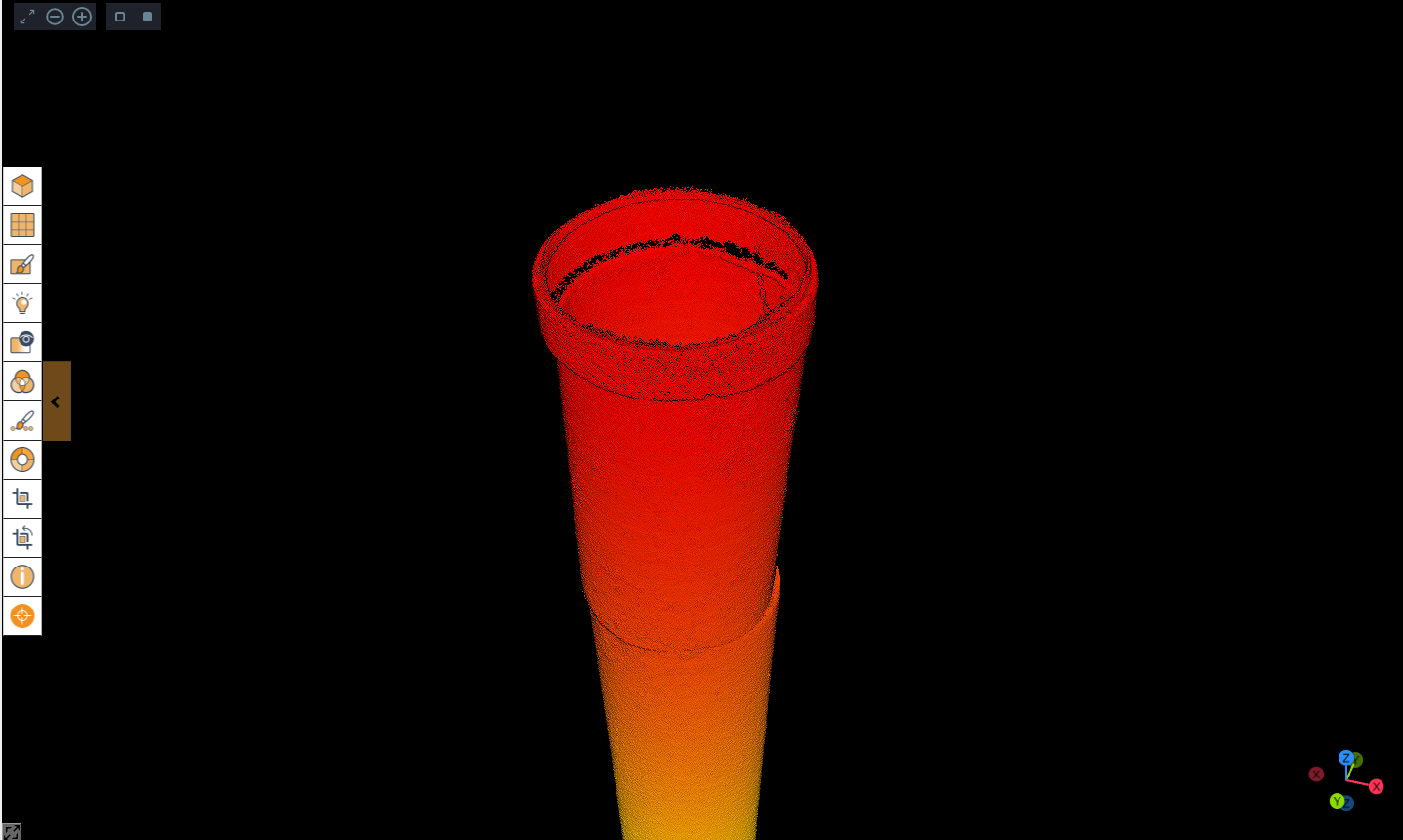

Visual and UT inspections are executed to check for damage and measure wall thickness respectively. By utilizing Birdseye drones with Ultrasonic Thickness (UT) measurement for maritime inspection, risk transformed into reality.

Key Outcomes

The use of the Elios 3 drone drastically improved the speed and safety of Cargo Oil Tank (COT) inspections. The table below outlines the comparative efficiency between traditional and drone-based inspection methods:

Inspection Time Comparison

| Method | Time per Tank | Tanks Inspected per Day | Total Time for 14 Tanks |

|---|---|---|---|

| Traditional | ~7 days | ~0.14 tanks/day | ~98 days |

| With Elios 3 Drone | ~0.5 day | 2 tanks/day | 7 days |

Operational Advantages

| Inspection Factor | Traditional Method | With Elios 3 Drone |

|---|---|---|

| Confined Space Entry | Required | Not required |

| Scaffolding | Required | Not required |

| Visual and UT Inspections | Done separately | Performed simultaneously |

| Speed Improvement | — | 6× faster |

Cost and Efficiency Impact

| Benefit | Impact |

|---|---|

| Labor Reduction | Fewer hours and personnel required |

| Vessel Downtime | Significantly reduced |

| Potential Cost Savings per Vessel | Up to $1 million |

| Data Accuracy & Reporting | Improved with simultaneous data capture |

Conclusion

The efficiency and precision enabled by drone technology, particularly the Elios 3, not only improved turnaround time but also minimized operational disruption and cost—delivering exceptional value to ship owners.