Overview

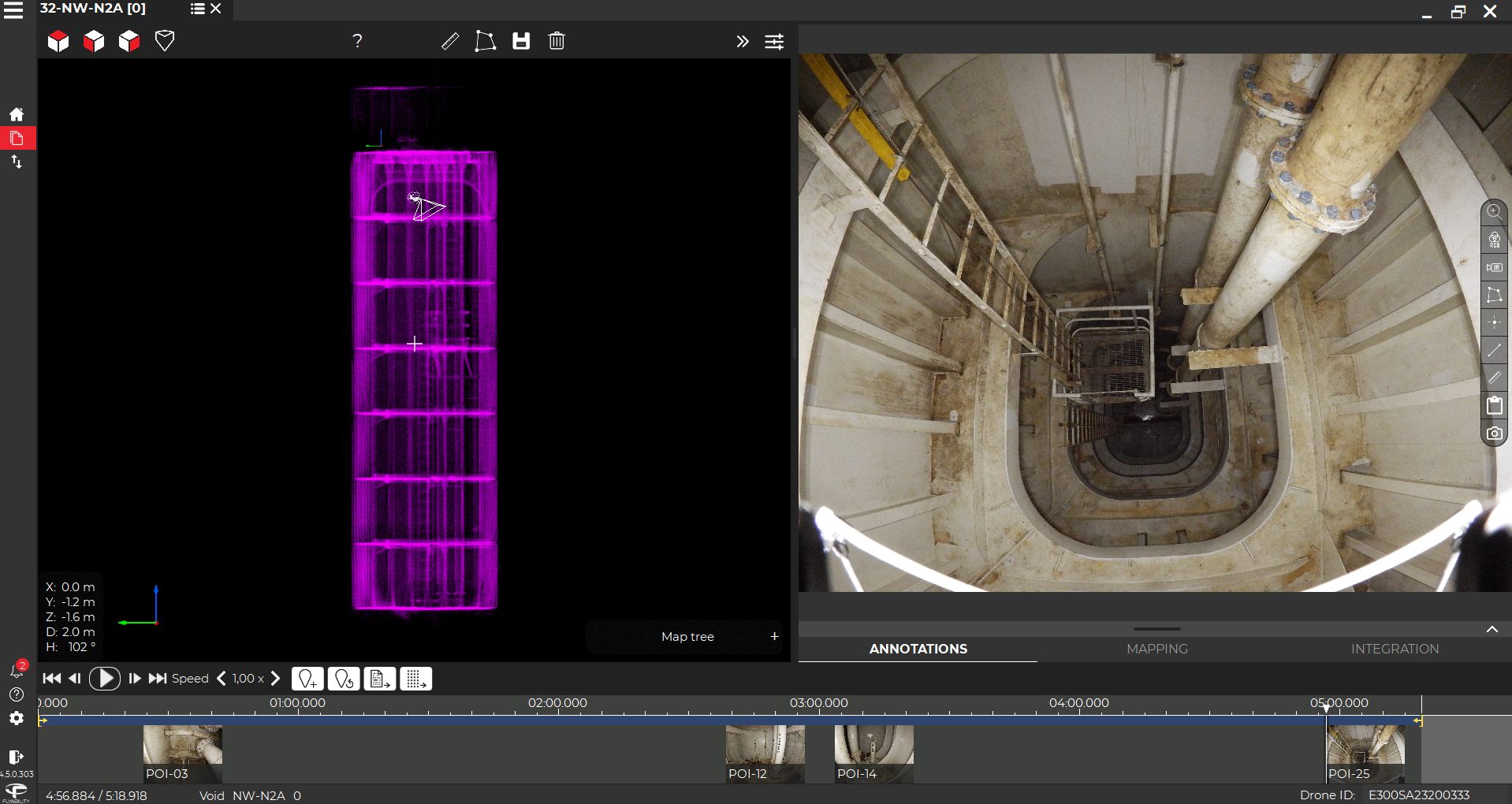

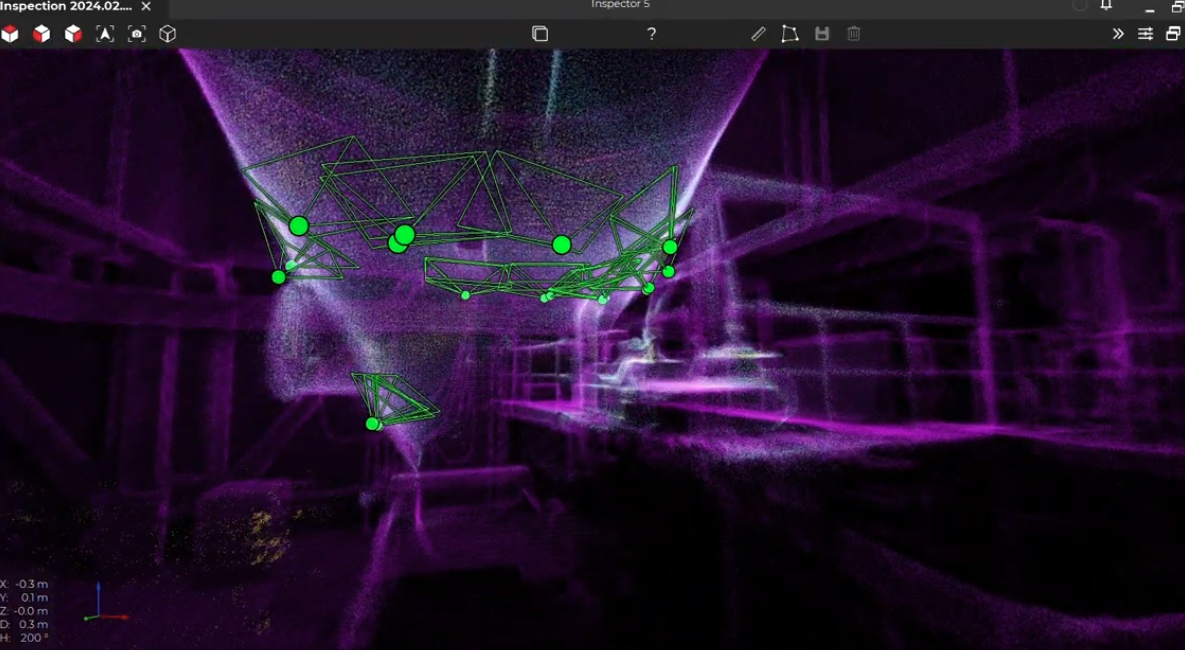

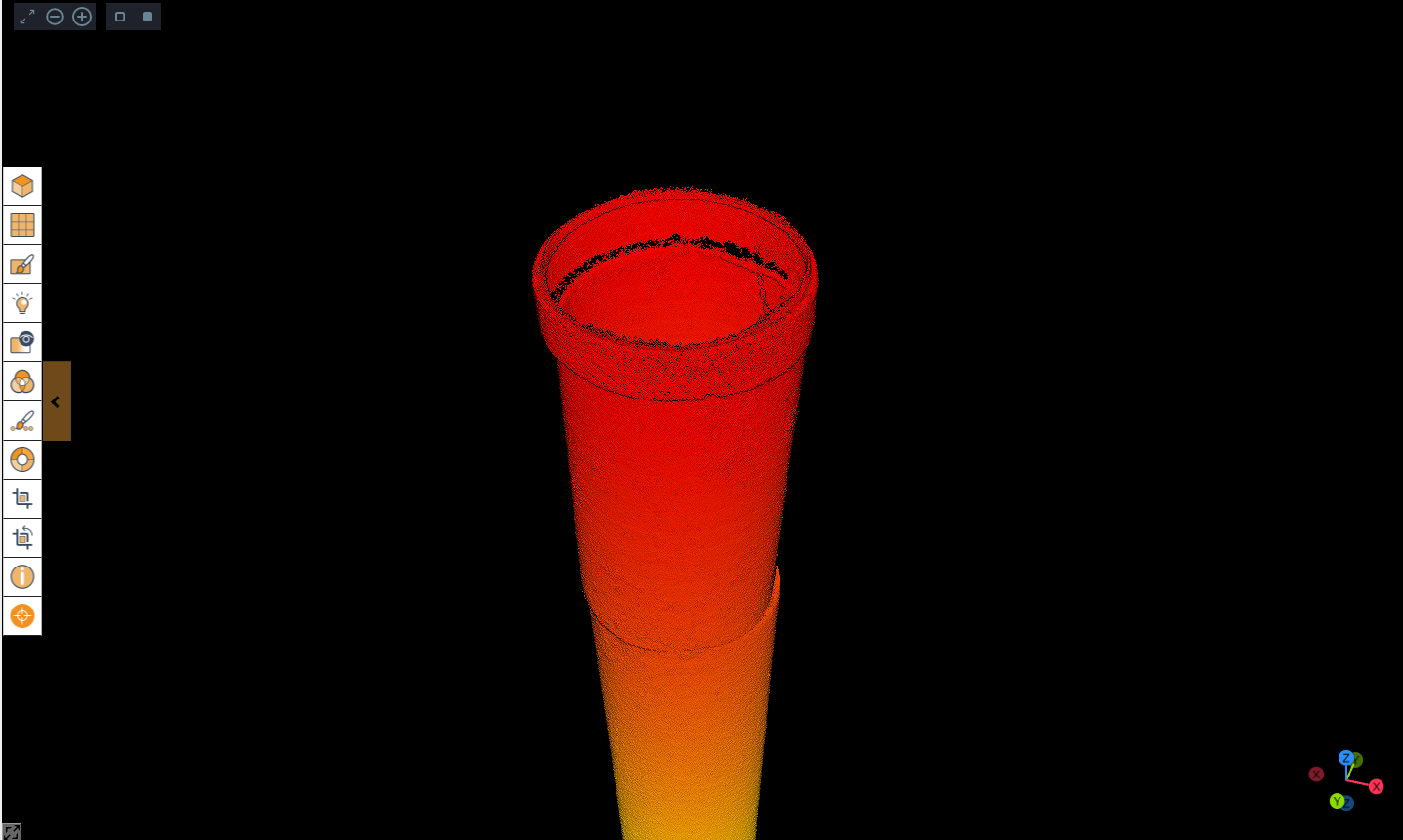

Birdseye’s Voliro T drone integrated with a Dry Film Thickness (DFT) gauge revolutionized the inspection of 380 kV transmission towers. It assessed the thickness of protective coatings, which is critical for ensuring structural integrity and long-term performance.

These towers are constantly exposed to harsh environmental conditions. Adequate coating thickness acts as a barrier against moisture and corrosive elements. Voliro T has now made it possible to integrate DFT measurements into routine inspections, enhancing tower protection and reliability.

Challenges

- Safety Risks in Manual Inspections: Traditional inspections involve climbing tall structures, increasing the risk of falls and worker injury.

- Maximized Operational Downtime: Power lines had to be shut down for safety during manual inspections, disrupting service and revenue flow.

- Time-Consuming Processes: Manual inspections are labor-intensive and reduce the number of towers that can be inspected daily.

Solutions Delivered by Birdseye

- Accelerated Safety and Efficiency: Voliro T with DFT gauges collects data without human entry, enhancing safety and reducing risk.

- Increased Inspection Efficiency: A single operator can inspect up to 10 towers per day, reducing time and labor costs.

- Minimized Downtime: Inspections can be conducted while the power lines remain active, avoiding service interruptions.

Outcome Summary

| Aspect | Impact |

|---|---|

| Safety | No human climbing needed; inspections done remotely by drone. |

| Efficiency | Up to 10 towers inspected daily by a single operator. |

| Downtime | Zero interruption to power lines during inspections. |

| Data Accuracy | Real-time, reliable coating thickness data captured for asset planning. |

Conclusion

The integration of Dry Film Thickness (DFT) measurement with Birdseye’s Voliro T drone has set a new benchmark for critical infrastructure inspection. It ensures safe, fast, and cost-efficient monitoring of coating integrity, even under demanding environmental conditions. With the ability to inspect up to 10 towers daily, this approach enhances planning accuracy, reduces risks, and protects long-term asset performance.