Overview

Working offshore is complex and demanding. If equipment breaks down or materials don’t arrive on time, it can cause serious delays, downtime, or safety risks. Since space is limited offshore, it’s significantly important to carefully balance inspections, maintenance, and daily operations to keep everything running efficiently.

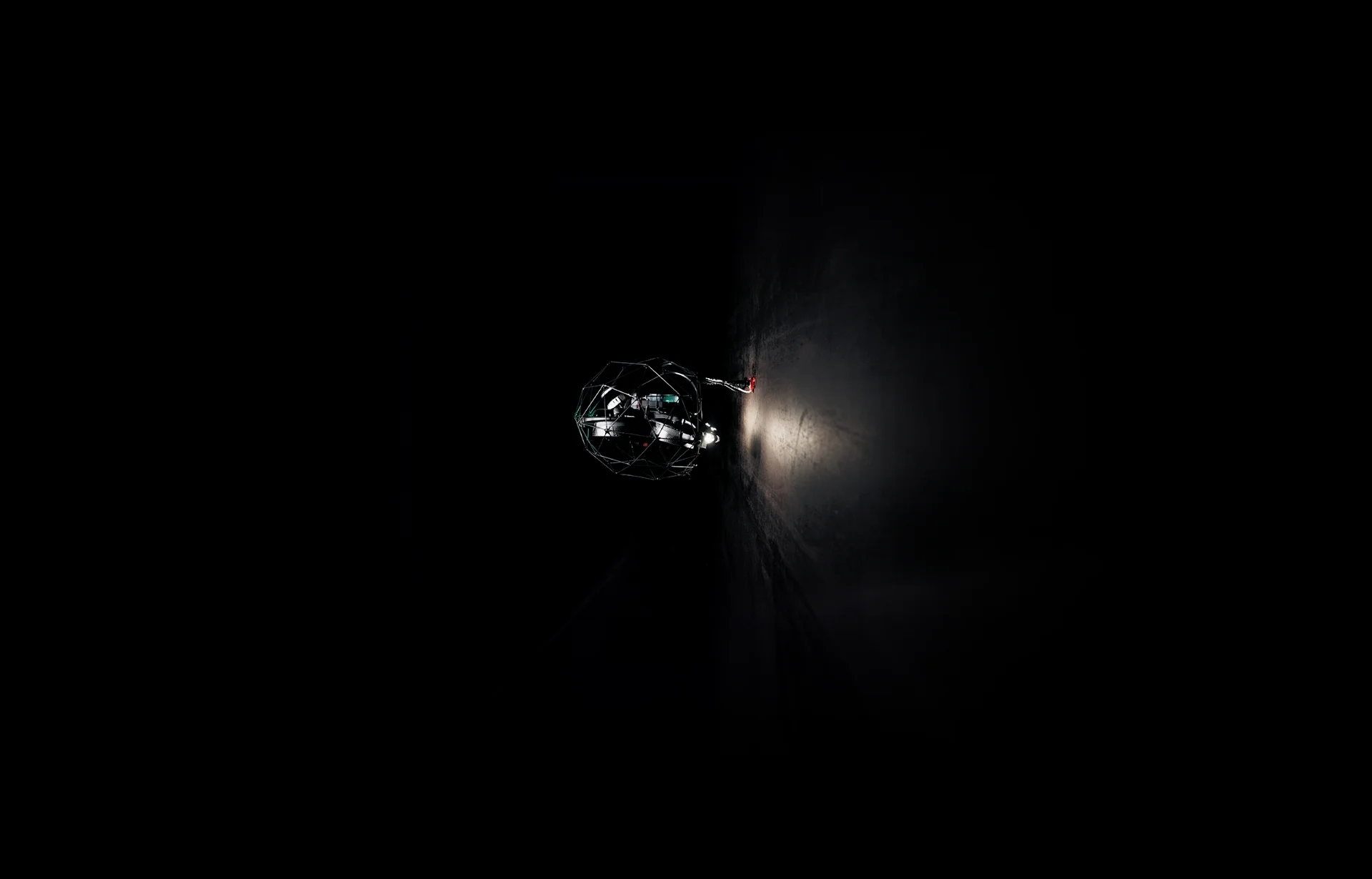

Stepping in as the game-changer, the Elios drone was leveraged to perform the tank inspections to save time at the rig.

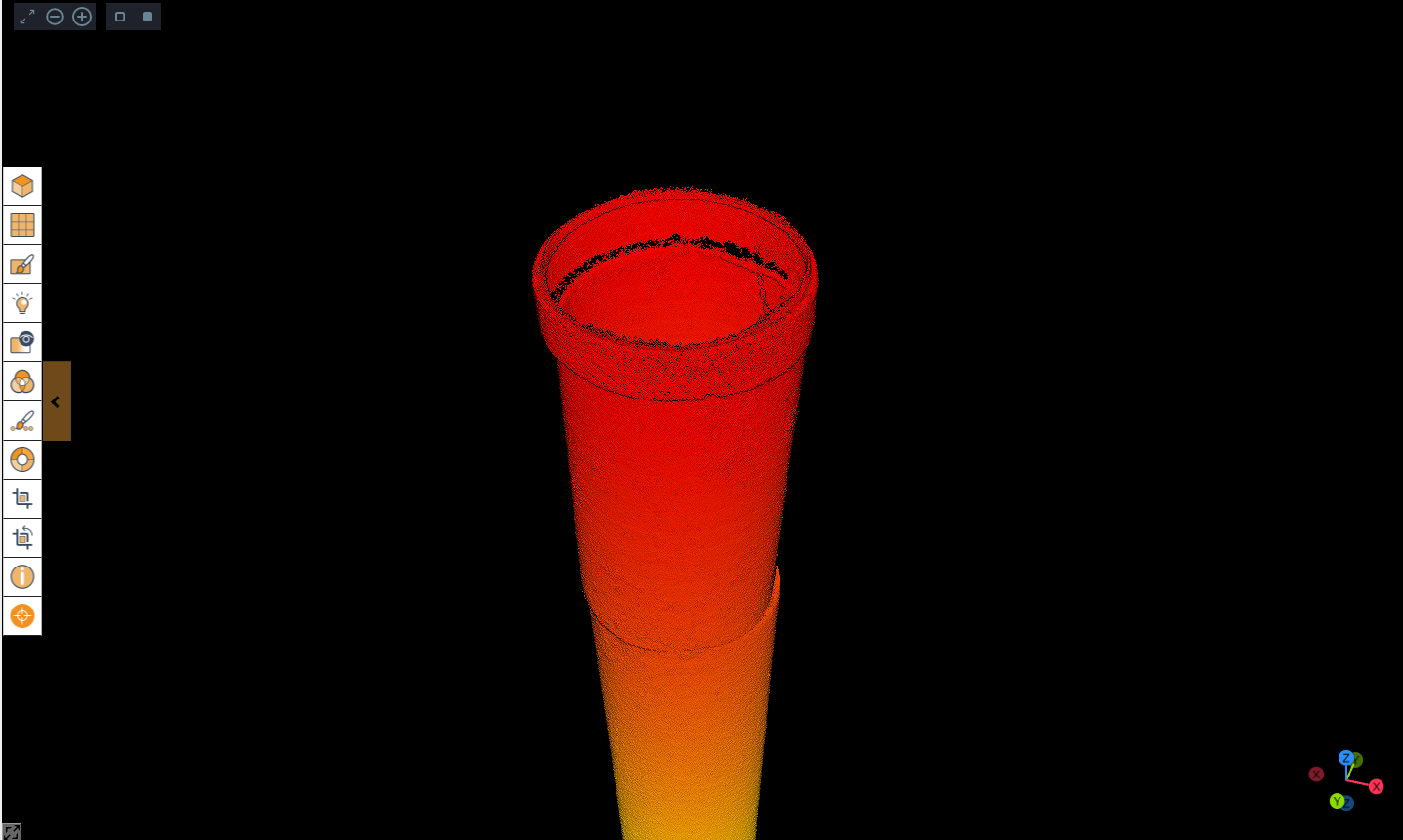

Large tanks had to be detected to gather data on their condition, examining for errors and detecting faults. Areas that needed to be worked on majorly were specifically highlighted.

Challenge

|

Labour Around 60 people on board ranging from engineers to general staff are required. |

Equipment & Time Ropes, various workers and an immense amount of time are taken to inspect several large tanks in 3R2. |

|

Regulatory Inspections As a decade-old facility, it has adhered to rigorous regulatory requirements. The inspection results are crucial for updating existing records. |

Permit for Entry In order for workers to begin the inspection process, a special permit had to be obtained. This added time and complexity. |

Results

Consists of 2 phases:

- The inspection team arrived at 3R-2 and began preparation for drone flights.

- ELIOS 2 performed initial scouting and reconnaissance of the tanks to streamline the main inspection flights.

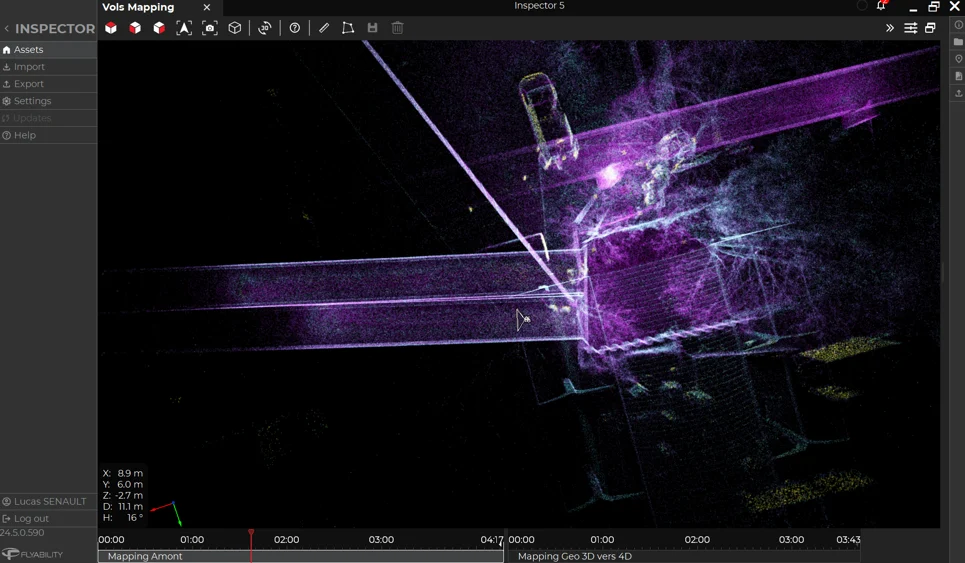

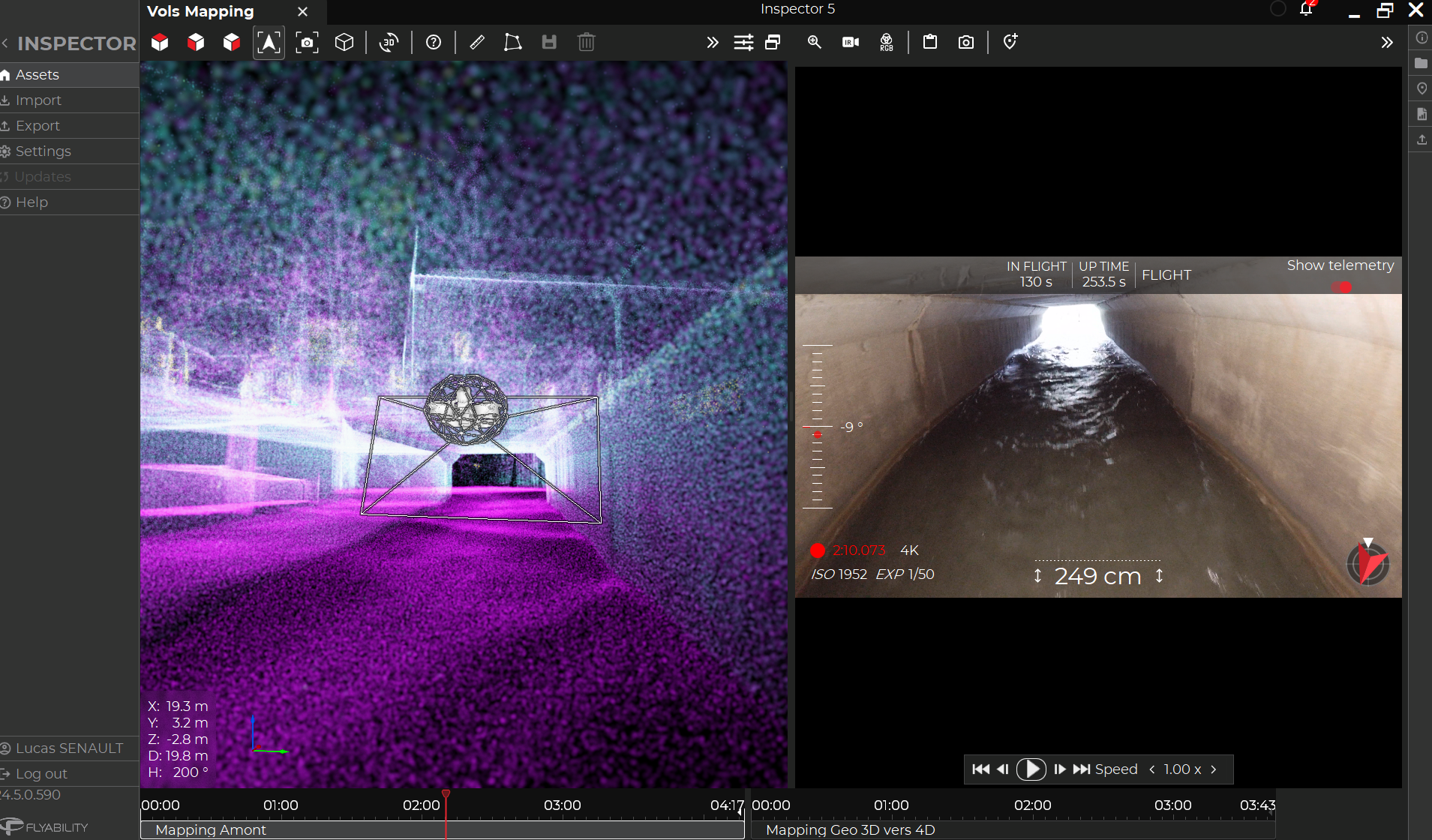

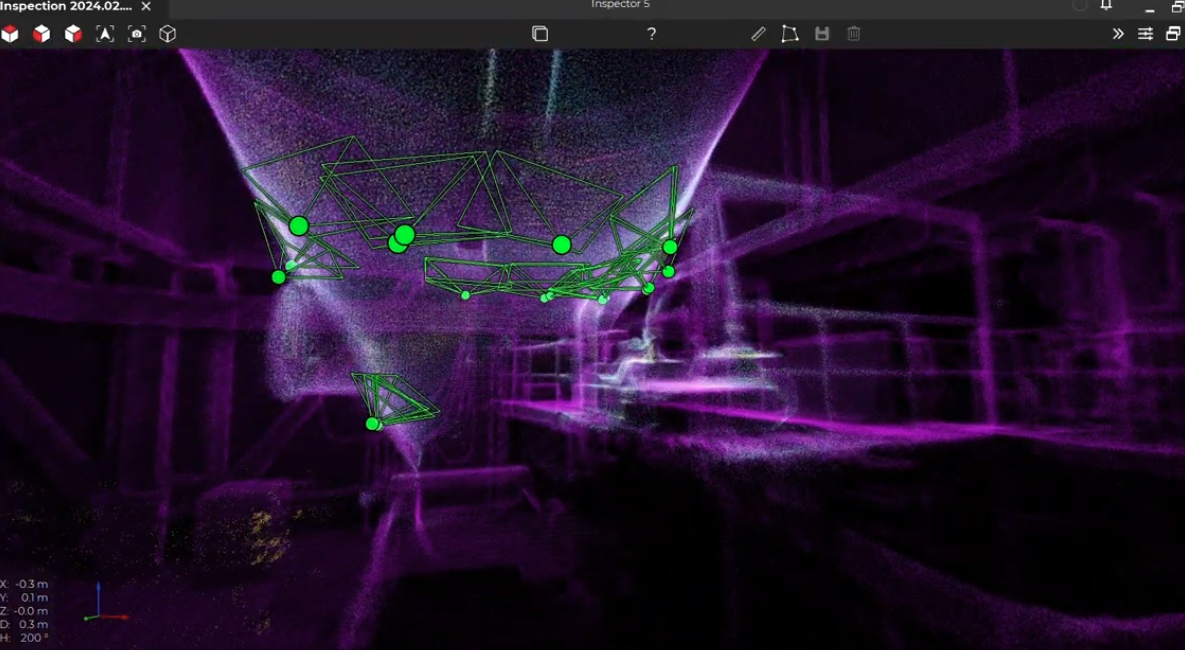

- ELIOS 3 was deployed to complete detailed scans and capture advanced data.

What Birdseye Delivered

| Time Taken for Inspection | 14 days, 10 hours |

| Number of Flights | 88 |

| Number of Tanks Inspected | 63 tanks |

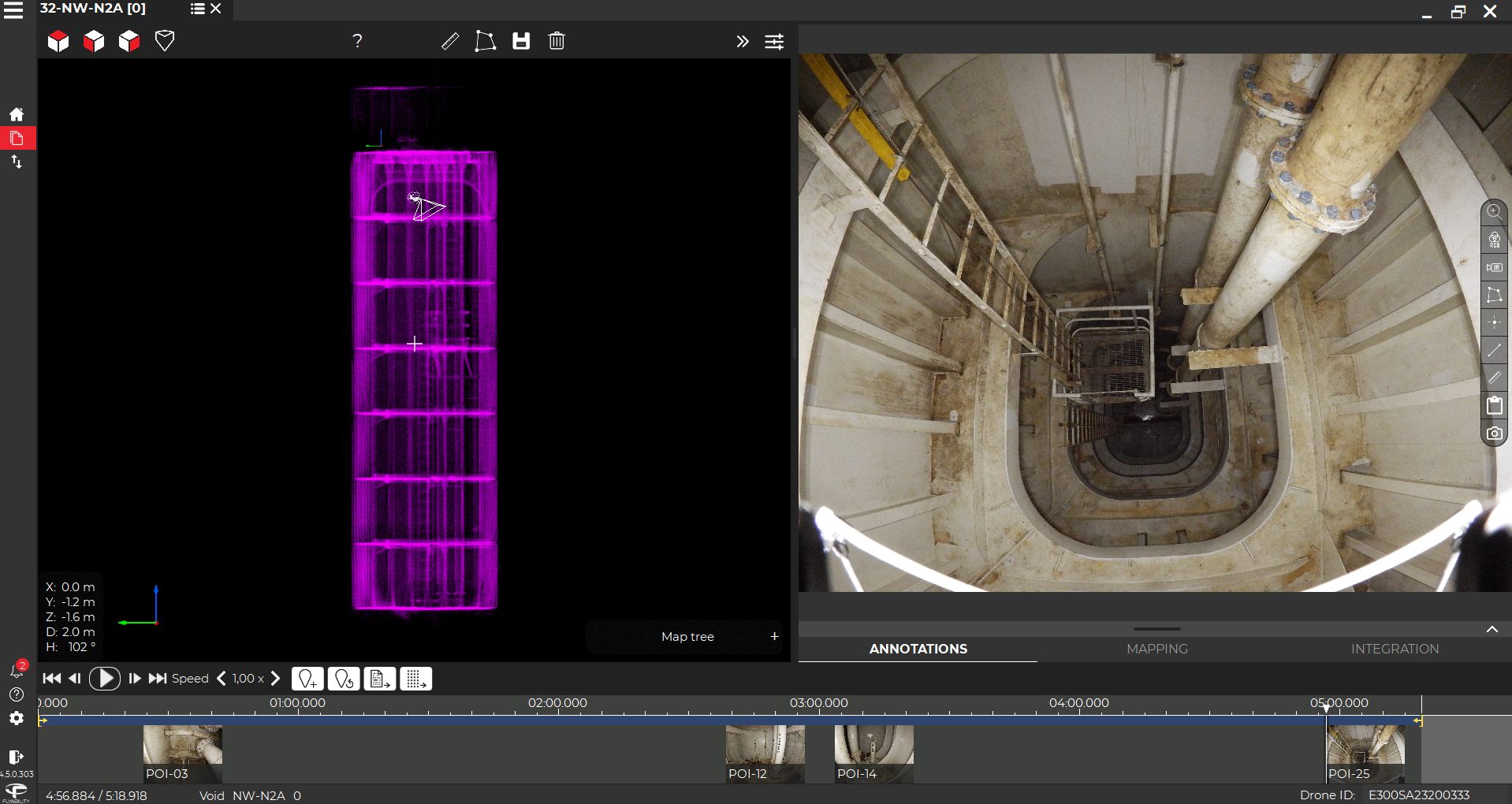

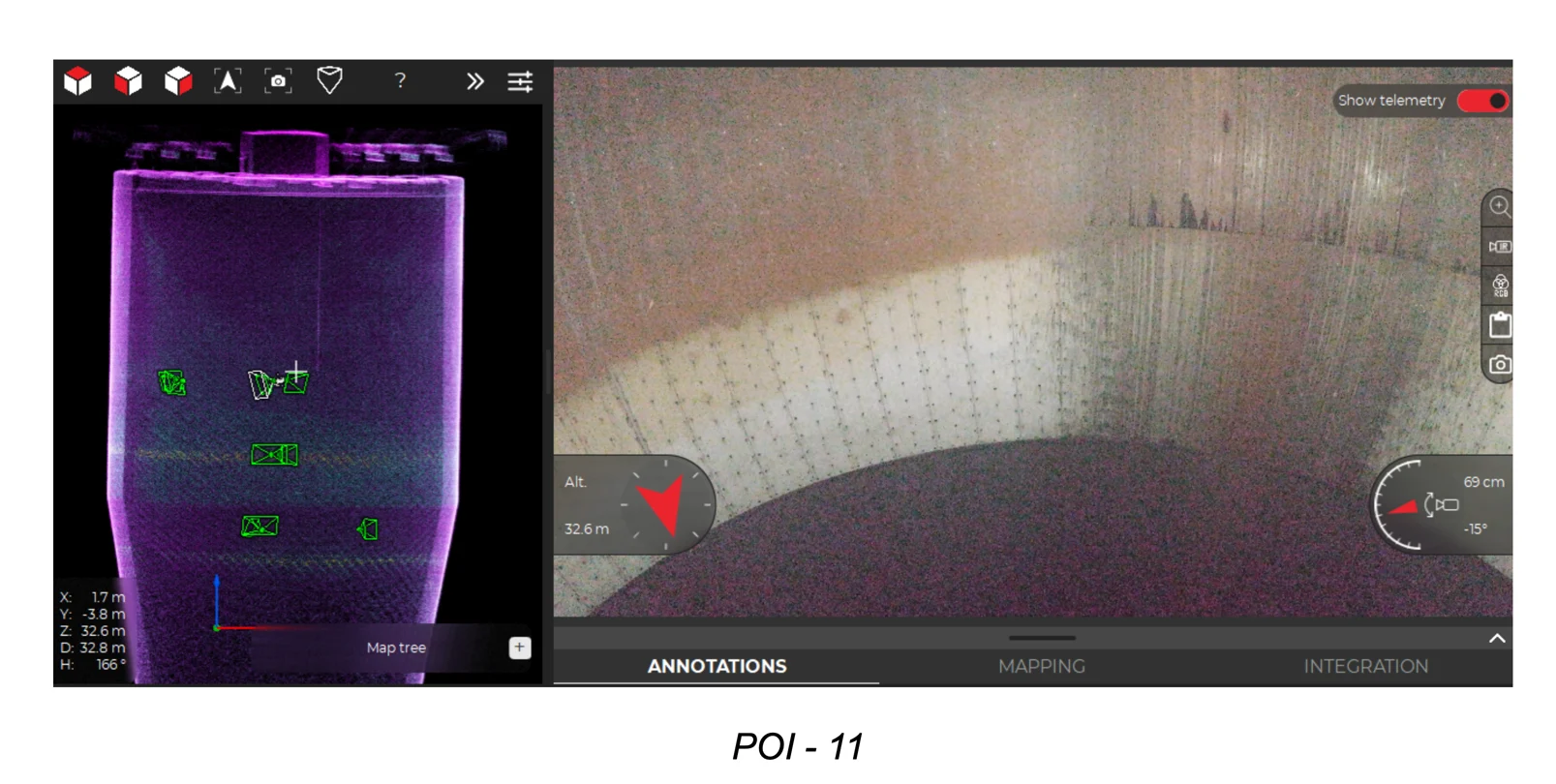

After successful drone flights, both Elios 2 and Elios 3 captured detailed data to update records and identify flaws. Elios 3’s LIDAR delivered a 3D model of the tanks’ interior to assess structural condition.

Conclusion

Using Birdseye’s inspection services equipped with Flyability’s Elios drones, the team achieved significant improvements in operational efficiency at the 3R-2 facility. These efficiencies translated into substantial time and cost savings for site managers, while also streamlining the movement of staff and inspectors—helping address the challenge of limited PoB (Personnel on Board). The Elios drones not only kept personnel out of confined and hazardous spaces but also captured high-quality data that met the regulatory standards set by the Class Society.

This approach helped tackle a major industry-wide challenge with both safety and compliance at its core.