Birdseye drones are revolutionizing the approach to sewer inspections by offering a safe, efficient, and cost-effective solution for assessing confined and hazardous environments. Designed to navigate the complexities of sewer systems, these drones eliminate the need for manual entry into dangerous spaces, thereby enhancing worker safety.

Equipped with advanced imaging and sensor technologies, Birdseye drones provide high-resolution data that facilitates accurate assessments and proactive maintenance, ensuring the integrity of critical infrastructure.

At Birdseye, we deliver advanced drone solutions designed specifically for sewer inspections. Here’s how we help utilities and inspection teams work smarter, faster, and safer.

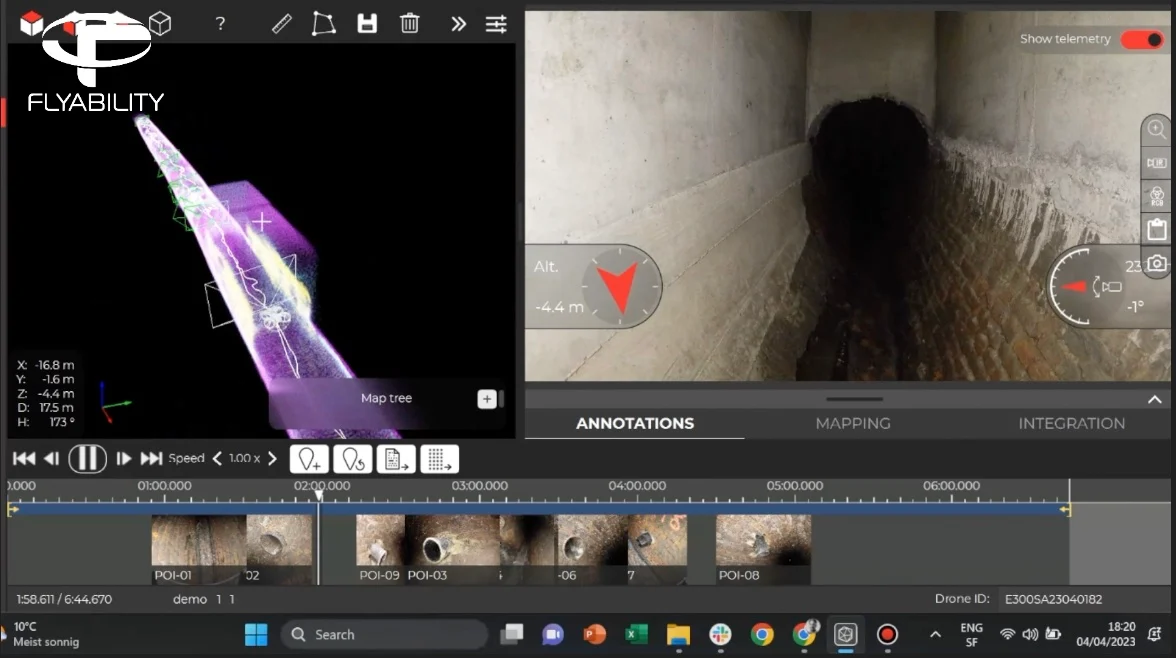

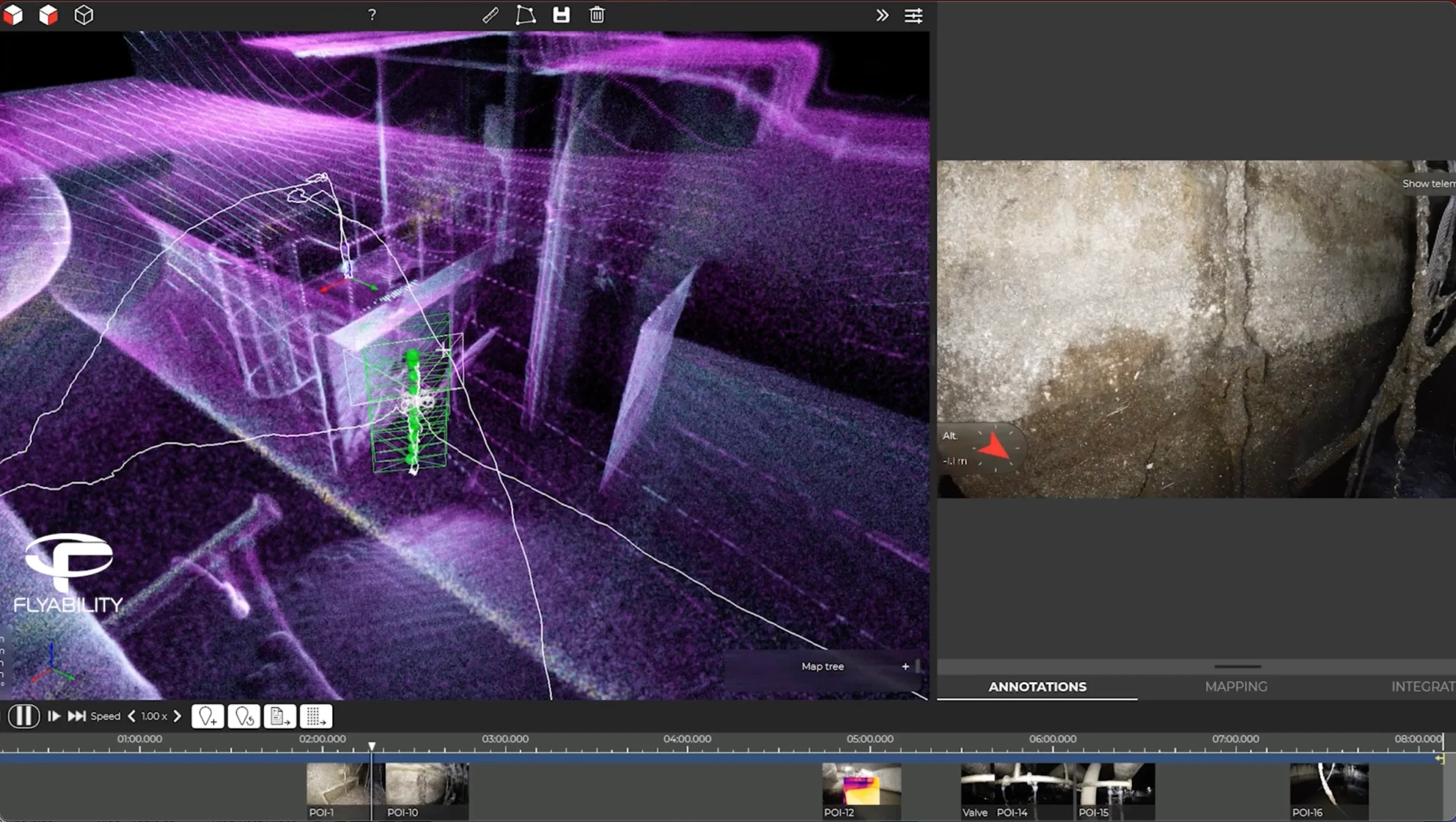

Our drones provide live video and generate 3D models on the fly, giving operators instant visibility for quick, informed decisions.

Drone inspections can cover up to 900 meters per day—more than double traditional methods—allowing teams to inspect more, faster.

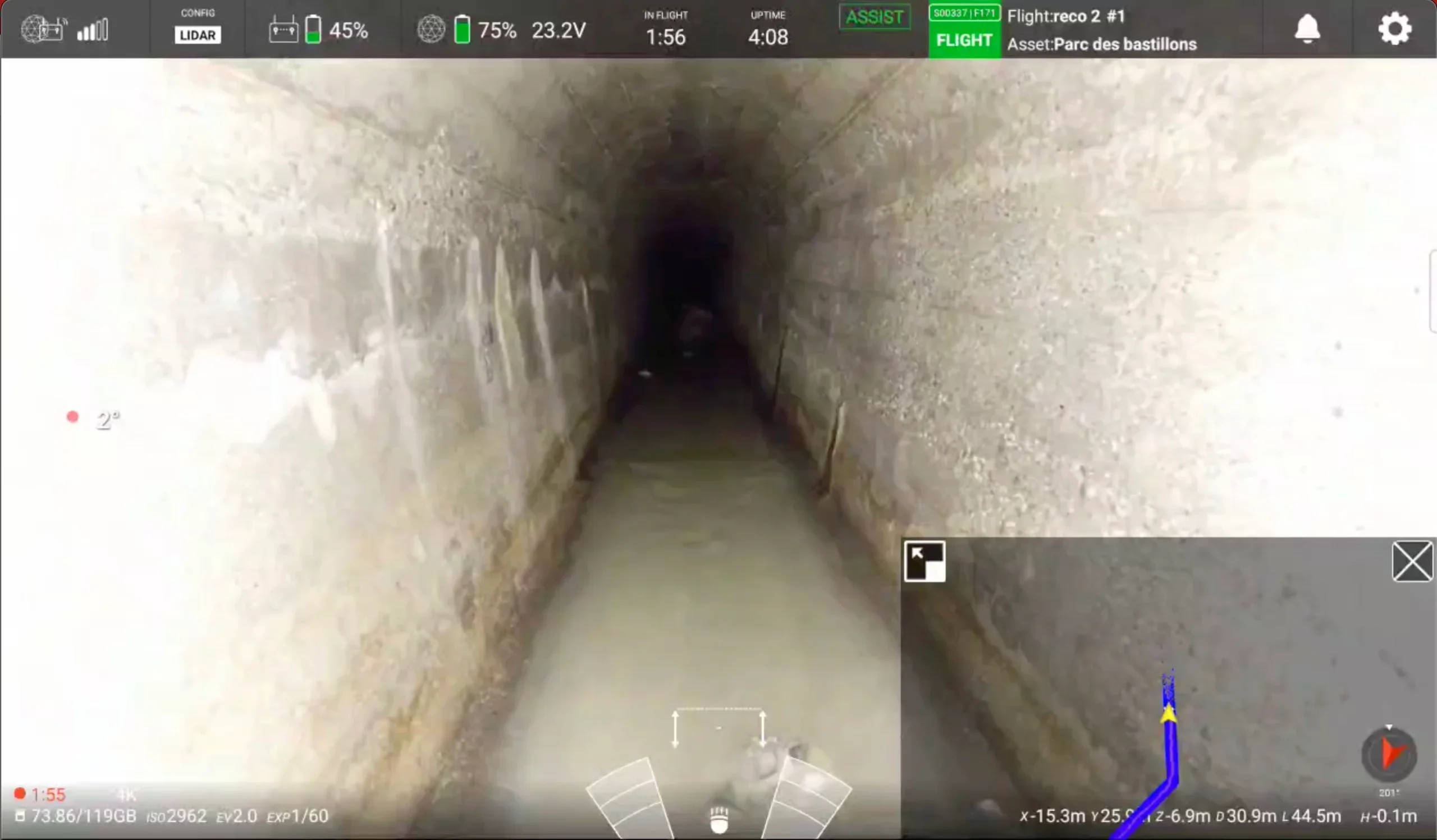

Access tight, dark, and debris-filled areas with full visual coverage—no blind spots, no missed defects.

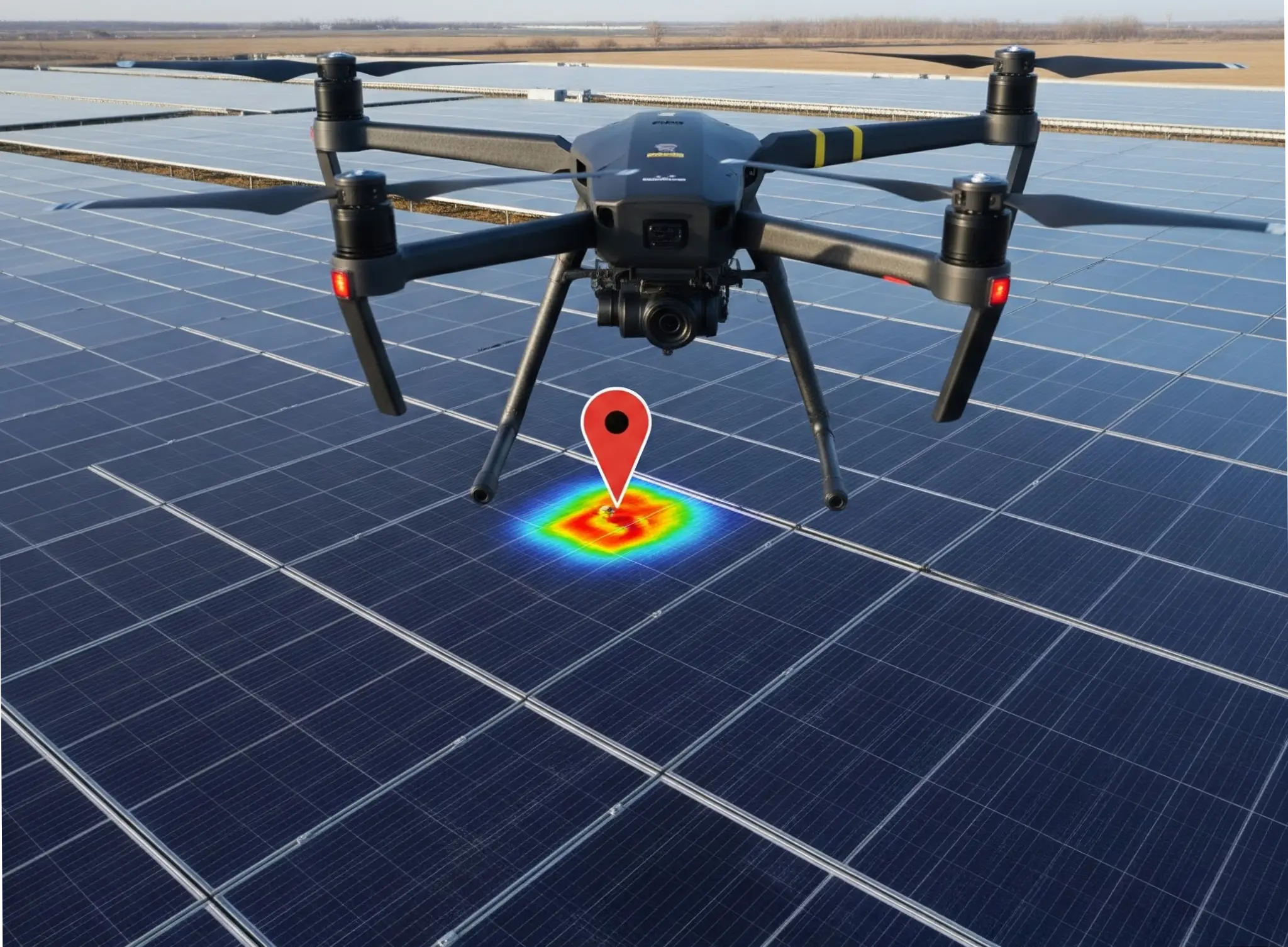

Using spatial data, inspectors can precisely locate faults, reducing guesswork and guiding accurate, efficient repairs.

Teams can dig exactly where needed—minimizing surface disruption, saving more time.

Drones eliminate the need for confined space entry, protecting workers and ensuring compliance with safety standards.

At Birdseye, we deliver advanced drone solutions designed specifically for sewer inspections. Here’s how we help utilities and inspection teams work smarter, faster, and safer.

Birdseye’s drones are built with a collision-resistant cage, making them ideal for tight and unpredictable sewer environments. High-lumen LED lighting, 4K video, and optional thermal imaging ensure clear visuals in dark, wet, and confined spaces—all while maintaining lightweight maneuverability.

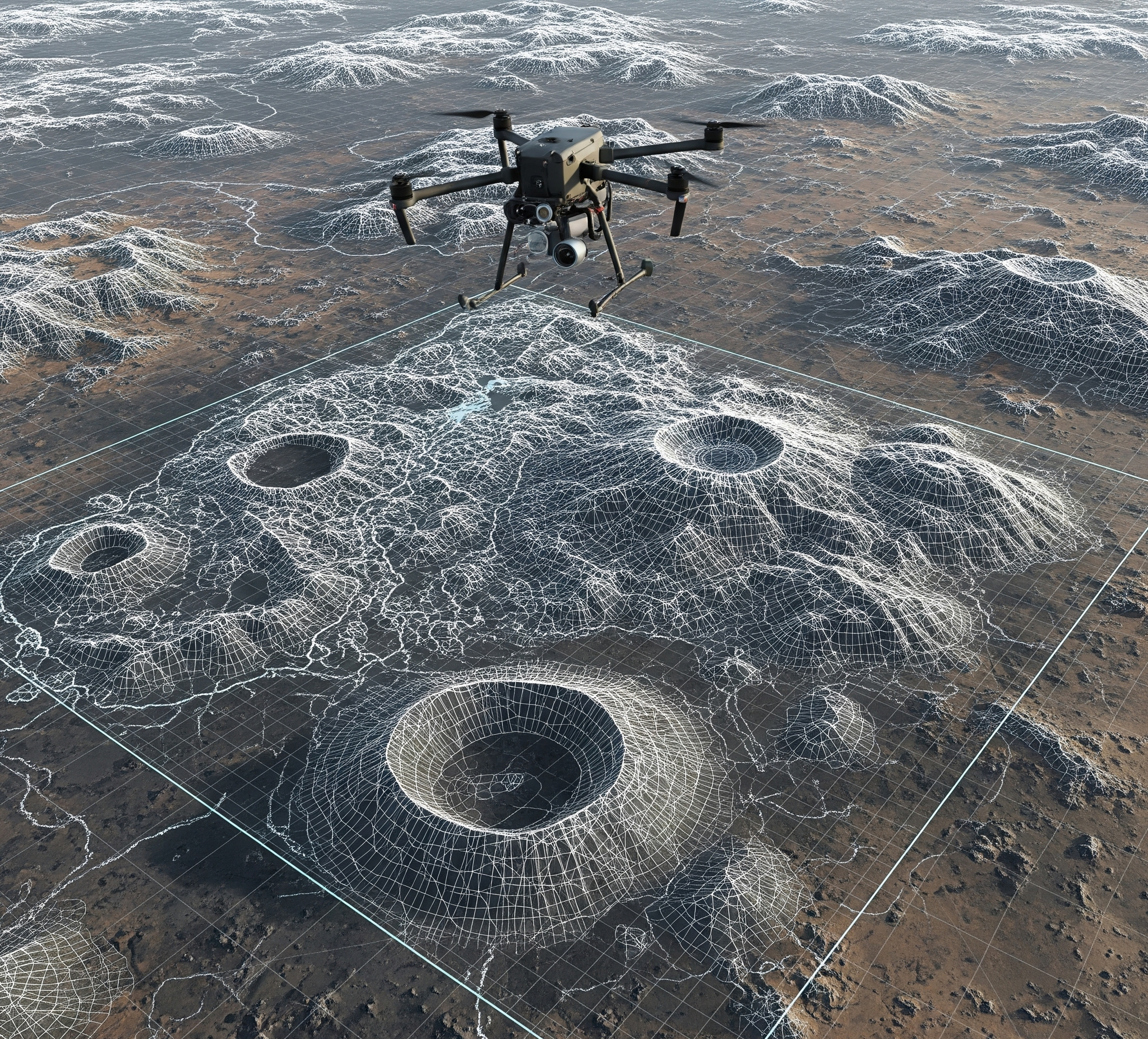

With visual-inertial odometry and optional LiDAR-based SLAM, drones maintain flight stability without GPS. This allows safe navigation through complex, low-light, GPS-denied spaces like pipelines and tunnels, while ensuring consistent orientation, even in low-feature or debris-heavy areas.

LiDAR-enabled models generate live 3D point clouds for immediate environmental awareness. These maps allow operators to monitor pipe geometry, detect deformation, and understand sewer layout—critical for post-collapse analysis or infrastructure modeling without waiting for offline processing.

Birdseye’s Inspector software synchronizes video, telemetry, and spatial data to tag and localize defects. Teams can generate inspection reports, export to CAD/GIS systems, and pinpoint exact defect locations, enabling precision maintenance with minimal excavation and operational downtime.

Encrypted live video feeds and intuitive ground control interfaces let inspectors assess sewer conditions in real time from above ground. Features like real-time playback, overlay data, and autonomous fail-safes keep operations smooth, safe, and compliant with industrial standards.

Birdseye supports ROS for robotic extensions and offers API access for workflow automation and system integration. Data can be embedded into asset management platforms, digital twins, or custom dashboards—empowering utility operators to turn inspection data into actionable infrastructure insights

By choosing Flyability for your sewer inspections, you’re choosing a safer, faster, and more efficient way to inspect and maintain your sewer systems. Let Birdseye bring the future of sewer inspection to your operations today.