Reimagine safety, speed, and precision in your mining operations—BirdsEye delivers actionable insights through high-performance drones and LiDAR technology, even in the harshest underground and open-pit conditions.

Mining today demands precision and speed. BirdsEye delivers both—while keeping boots off the ground.

“We used to send teams in with flashlights.

Now, we send Birdseye drones with LiDAR

and get a 3D map back in hours.”

– Our Client Says

Competitors rely on photogrammetry, which fails in dusty shafts. BirdsEye’s LiDAR “sees” through smog—no lighting required.

Speed | Ease of use | Accuracy |

10 min to capture high resolution point cloud data | Create a live 3D map and locate the drone and its exact trajectory | Detailed 3D insights with 100% coverage |

Speed | Safety | Accuracy |

9 min to capture the data with Elios (one flight) | No work at height. The data is collected from a safe distance | 3D models provide accurate stockpile calculations |

Speed | Access | Accuracy |

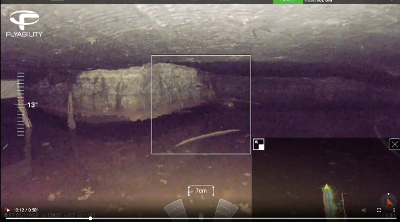

~10 min to find the cause of an ore pass hang-up | Fly directly into the ore pass and gather both visual and LiDAR data | Geolocalize the hang-up in the ore and see exactly how the hang-up looks like |

Speed | Access | Safety |

~8 min to inspect 2 Ore passes and a small stop | 100% data coverage even in no-go zones | No workers exposed to hazards |

Speed | Cost Efficiency | Safety |

Deploy a drone on demand without the need for elaborated safety procedures and/or complex scaffolding | Perform inspections without stopping the production with one pilot only vs. standard teams of 3-4 people | No workers exposed to hazards |

Speed | Access | Safety |

Deploy a drone on demand without the need for complex safety procedures | Get 100% data coverage—even in no-go zones | No workers exposed to hazards |

What you get with every BirdsEye mission:

All data delivered securely via cloud within 24–48 hours. GIS-ready and shareable with your internal teams.