Our explosion-proof drones deliver high-resolution visuals, thermal data, and AI-driven insights — helping chemical plants stay compliant, operational, and ahead of failures.

Inspect flare stacks, tanks, and pipelines in hours, not days

No production interruptions for inspections

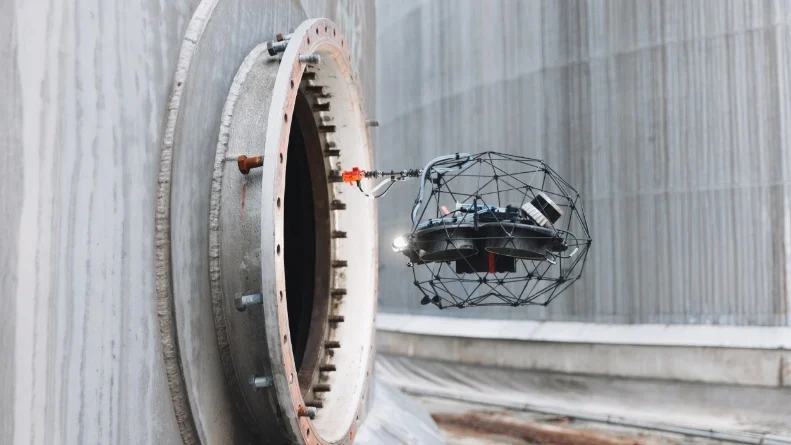

ATEX-certified drones for hazardous Zone 1/2 areas

Compliant with OSHA, EPA, API 510/570 standards

Instant reports with prioritized risks

Oil & gas assets are complex, hazardous, and costly to inspect. Our drones make inspections safer, faster, and more efficient—especially in confined spaces, elevated structures, and other high-risk environments.

Challenge | Traditional Method | Our Drone Solution |

|---|---|---|

200-ft Flare Stack Inspection | 3-day shutdown + $250k lost production | 2-hour flight, no shutdown |

Storage Tank Corrosion Mapping | Scaffolding + 5-person crew for 1 week | 1 drone + 1 pilot = 1 day |

Gas Leak Detection | Handheld sensors with limited coverage | 100% aerial coverage with OGI cameras |

Challenge | Traditional Method | Our Drone Solution |

|---|---|---|

200-ft Flare Stack Inspection | 3-day shutdown + $250k lost production | 2-hour flight, no shutdown |

Storage Tank Corrosion Mapping | Scaffolding + 5-person crew for 1 week | 1 drone + 1 pilot = 1 day |

Gas Leak Detection | Handheld sensors with limited coverage | 100% aerial coverage with OGI cameras |

Our certified pilots and engineers go beyond data capture—we deliver insights that drive Reliability-Centered Maintenance (RCM).

By combining drone inspections with deep oil & gas expertise, we help you prioritize maintenance based on asset criticality, failure modes, and operational impact—reducing downtime and extending asset life.

It’s not just technology—it’s actionable intelligence you can trust.

Our drones are built to inspect a wide range of chemical plant assets, including: